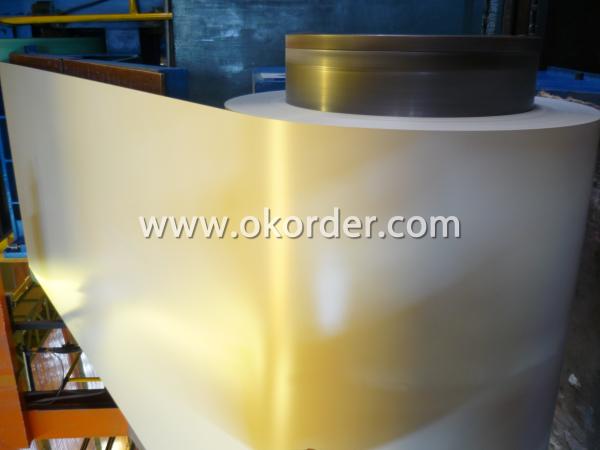

Best Quality for White Prepainted Galvanized Steel

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50MT m.t.

- Supply Capability:

- 10000 tons per month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Information of White Prepainted Galvanized Steel

With GI as base metal, after pretreatment (degrease and chemical treatment) and liquid dope with several layers of color, then after firing and cooling, finally the plate steel is called pre-painted galvanized steel. Pre-painted galvanized steel is good capable of decoration, molding, corrosion resistance. It generally displays superior workability, durability and weather resistance.

Specification of White Prepainted Galvanized Steel:

1. Thickness 0.23-1.2mm (BMT)

2. Zinc Coating 80-275g/m2

3. Color According to RAL color fan Internal

4. Diameter 508mm or 610mm

5. Coil Weight 4-8MT

6. Quality Commercial and structural quality

7. Paint Polyester paint for topside, epoxy for reverse

8. Standard JIS G 3312, ASTM A755M, EN 10169

9. Base Steel Grade SGCC,SGCD,DX51D+Z,DX52D+Z;S200GD,S220GD, S280GD,S350GD,CS,FS,SS

Chemical Composition of White Prepainted Galvanized Steel

C | Si | Mn | P |

0.04-0.06% | 0.01-0.03% | 0.18-0.22% | 0.014-0.016% |

Technical Data of White Prepainted Galvanized Steel

Yield Strength | (Mpa) 280-320 |

Tensile Strength | (Mpa) 340-390 |

Elongation | 20%-30% |

Reverse Impact | 9J |

T-bending | ≥2T |

Pencil Hardness | ≥2H |

Duration Of Salt Spray Test | 500 H |

Bending At 180 Degree | No crack, purling and fraction |

Application of White Prepainted Galvanized Steel

Outdoor:

roof, roof structure, surface sheet of balcony,

frame of window, door, door of garage, roller shutter door, booth, Persian blinds, cabana, etc.

In door:

door, isolater, frame of door, light steel structure of house, home electronic appliances, etc.

Packaging & Delivery of White Prepainted Galvanized Steel

Anti-damp paper inside full wrapped with plastic film, iron sheet outside on wooden pallet in 20 feet container with 25mt.

- Q:What are the different types of steel shelving and storage systems available?

- There are several types of steel shelving and storage systems available, including boltless shelving, industrial shelving, wire shelving, and pallet racking. Boltless shelving is easy to assemble and disassemble, making it a popular choice for warehouses and garages. Industrial shelving is heavy-duty and designed to hold large and bulky items. Wire shelving is lightweight and allows for good air circulation, making it suitable for storing items that may need ventilation. Pallet racking is designed to store palletized goods and is commonly used in warehouses and distribution centers.

- Q:How is steel coil produced?

- Steel coil is produced through a process called hot rolling, where a slab of heated steel is passed through a series of rollers to reduce its thickness and shape it into a long, coiled strip. This strip is then cooled and processed further to achieve the desired quality and specifications before being cut into individual coils for various industrial applications.

- Q:What are the different types of steel tanks and their applications in the food processing industry?

- There are several types of steel tanks used in the food processing industry, including stainless steel tanks, carbon steel tanks, and alloy steel tanks. Stainless steel tanks are the most common type, known for their corrosion resistance and hygienic properties. They are widely used for storing and processing various food products such as dairy, beverages, sauces, and oils. Carbon steel tanks, on the other hand, are less expensive but require additional measures to prevent corrosion. They are commonly used for bulk storage of dry food ingredients like grains, flour, and sugar. Alloy steel tanks are a specialized type that offers enhanced strength and durability. They are utilized in food processing applications that involve high-pressure processes or extreme temperature conditions, such as canning or sterilization. Overall, steel tanks play a crucial role in the food processing industry, ensuring proper storage, transportation, and processing of food products while maintaining hygiene and safety standards.

- Q:What are the different grades of tool steel and their applications?

- Tool steel is a type of high-quality carbon or alloy steel that is specifically designed for use in the manufacturing of tools and machinery parts. There are several different grades of tool steel, each with its own unique properties and applications. Some common grades include: 1. O-1 Tool Steel: This grade is known for its excellent hardness, wear resistance, and toughness. It is commonly used in making cutting tools, punches, and dies. 2. A-2 Tool Steel: A-2 grade offers good wear resistance and machinability. It is often used in applications requiring high production rates and precision, such as forming dies and precision measuring tools. 3. D-2 Tool Steel: D-2 grade is a high-carbon, high-chromium, and high-molybdenum steel. It exhibits excellent wear resistance and can retain its hardness even at high temperatures. It is widely used in making cutting tools, shear blades, and cold work punches. 4. H-13 Tool Steel: H-13 grade is a hot work tool steel with excellent heat resistance and high toughness. It is commonly used in applications that involve high temperatures, such as die casting, extrusion, and hot forging. 5. M-2 Tool Steel: M-2 grade is a high-speed tool steel known for its exceptional hardness and heat resistance. It is commonly used in making drills, reamers, and other cutting tools that require high-speed machining. These grades are just a few examples, and there are many other tool steel grades available, each suited for specific applications. The choice of grade depends on factors such as the desired hardness, wear resistance, toughness, and the specific tool or part being manufactured.

- Q:What are the different types of steel bars and rods available?

- There are several different types of steel bars and rods available, including mild steel bars, carbon steel bars, alloy steel bars, stainless steel bars, and tool steel bars. Each type varies in terms of its composition, strength, and intended use.

- Q:How do steel products contribute to the construction of research laboratories and scientific facilities?

- Steel products play a crucial role in the construction of research laboratories and scientific facilities. Steel is widely used as a structural material due to its high strength, durability, and ability to withstand extreme environmental conditions. It provides the necessary framework for these complex structures, ensuring their stability and longevity. Additionally, steel is often used in specialized equipment and infrastructure within the laboratories, such as fume hoods, ventilation systems, and lab benches. Its versatility and adaptability allow for the creation of customized solutions to meet the unique needs of scientific research. Overall, steel products contribute significantly to the construction and functionality of research laboratories, facilitating the advancement of scientific knowledge and innovation.

- Q:What are the different types of steel products used in the manufacturing of tools and machinery?

- There are several types of steel products used in the manufacturing of tools and machinery. Some common examples include carbon steel, alloy steel, stainless steel, and tool steel. Carbon steel is widely used due to its strength and affordability. Alloy steel contains additional elements such as chromium, nickel, and molybdenum to enhance specific properties like hardness and corrosion resistance. Stainless steel is favored for its resistance to rust and staining, making it suitable for tools and machinery used in moisture-prone environments. Tool steel is specifically designed for tool-making, offering high hardness, wear resistance, and toughness.

- Q:How is steel used in the production of medical devices?

- Steel is commonly used in the production of medical devices due to its strength, durability, and biocompatibility. It is used to manufacture various surgical instruments, implants, and other equipment that require precision, reliability, and resistance to corrosion.

- Q:How is steel used in the production of HVAC systems?

- Steel is commonly used in the production of HVAC systems due to its strength, durability, and resistance to corrosion. It is utilized to fabricate various components such as ductwork, pipes, and heat exchangers, ensuring the system's structural integrity and longevity.

- Q:How do steel products contribute to the construction of theme-based culinary experience centers?

- Steel products contribute to the construction of theme-based culinary experience centers by providing structural support and durability to the buildings. Steel beams, columns, and frames are used to create the framework of the centers, ensuring stability and safety. Additionally, steel is often used for the fabrication of kitchen equipment, such as countertops, shelves, and cooking appliances. Its strength and resistance to heat and corrosion make it an ideal material for creating a functional and aesthetically pleasing culinary environment.

1. Manufacturer Overview |

|

|---|---|

| Location | Jiangsu, China |

| Year Established | 2003 |

| Annual Output Value | US$1 Million - US$2.5 Million |

| Main Markets | Southern Asia; America; South America; Eastern Europe |

| Company Certifications | ISO 9000 ISO 14000 OHSAS 18000 |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 1% - 10% |

| No.of Employees in Trade Department | 100 People |

| Language Spoken: | English; Chinese |

| b)Factory Information | |

| Factory Size: | Above 200,000 square meters |

| No. of Production Lines | 14 |

| Contract Manufacturing | Design Service Offered |

| Product Price Range | Average |

Send your message to us

Best Quality for White Prepainted Galvanized Steel

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50MT m.t.

- Supply Capability:

- 10000 tons per month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords