Best Quality Aluminum Ceiling China Supplier

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Type: | Place of Origin: | Brand Name: | |||

| Model Number: | Function: | Feature: | |||

| Ceiling Tile Shape: | Ceiling Tile Type: | Surface Treatment: | |||

| Metal Ceiling Material: | Key word: | Specification: | |||

| Height: | Thickness: | Perforated diameter: | |||

| Color: | MOQ: | Delivery time: | |||

| Packing: | Certificate: |

1) Our clip in aluminum ceiling:

Clip in square ceiling, widest applicable among all type of ceiling with outstanding advantages. Plain or pattern can be selected according to the actual requirement. Clip in system which is concealed, steady structure, flat surface, could be both used as ceiling and wall panel.

2) Specifications:

| Specification | Thickness | Height | Legend |

| 300×300mm | 0.4-1.0mm | 19mm(short edge) 25mm(High edge) |  |

| 300×450mm | |||

| 300×600mm | |||

| 300×1200mm | |||

| 400×400mm | 0.5-1.2mm | ||

| 500×500mm | |||

| 600×600mm | |||

| 600×1200mm | |||

| Base materials | Aluminum alloy, the grade of aluminum alloy can be selected according to the actual requirements; Besides, galvanized iron and stainless steel material is also available | ||

| Surface treatment | Powder coated(ordinary powder, Polyester powder), Paint coated, Film coated | ||

| Type of Surface | Plain plate or perforated plate is selected according to the actual requirements | ||

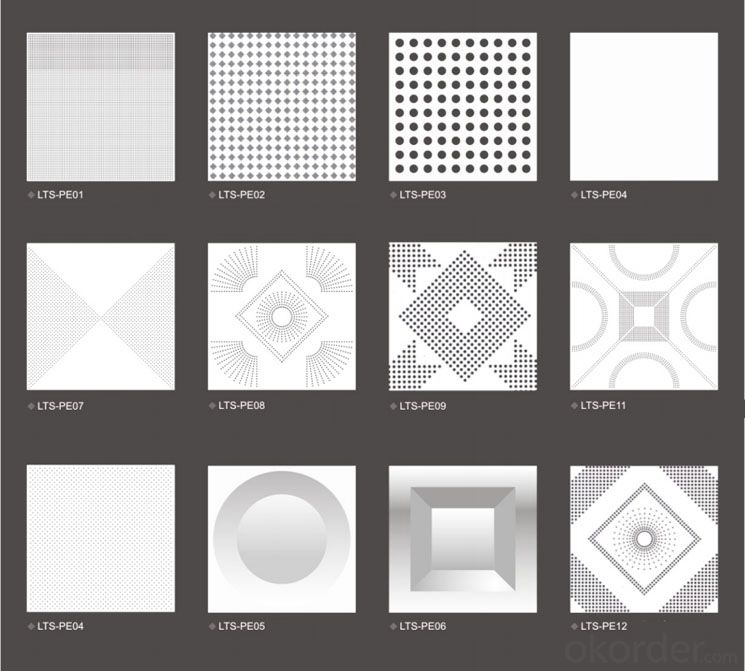

3) perforated pattern:

Perforation is a kind of processing technology for metal ceiling.Ceiling design beautiful patterns according to the arrangement of perforated holes with powerful sound absorbing and isolating effect. Rators possesses over 40 kinds of fixed perforated types, and could be customized according to client's requirements on patterns, sound absorbing to meet the actual situation.

4)Our Packing:

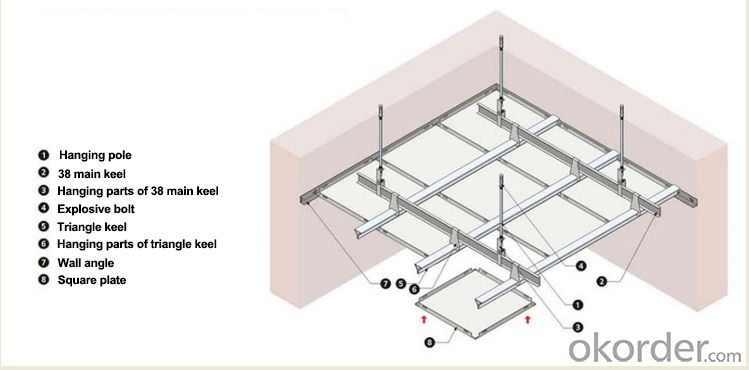

5)Installation Method:

The upper main keel and lower triangle keel are tightly connected with "cross" structure,therefore,it can assure the levelness of whole suspended system with more solid structure.

6)Sample Project:

7)Application:

mainly used in project for big area with soundproof requirements, such as hotels,stores,office building, hospitals,railway stations,metro stations and so on.

8)Certificate:

ISO9001:2008, BV,TUV, Product Quality Certificate.

9)Factory Tour:

Installaiton & Accessories.

*Clip-In Panels are constructed of recycled aluminum

*Springs and clips are constructed of high performance steel

*Clip-In Panels integrate into and conceal 15/16” face HD/ID suspension grid

*Clip-In Panels for use in interior application

*Square edge design

*Standard sizes of 24” x 24”, 24” x 48” or custom size

*Clip-In Panels available in solid or perforated designs

*Clip-in placement allows for downward accessibility without special tools

*Easily incorporates air, fire, audio and other services

*Panels contain no organic compounds that support mold or microbial growth

*Factory applied, no-VOC powder coated paints and laminated finishes

- Q:Home improvement aluminum plate thickness in the end is how much is considered good

- Home decoration aluminum plate is not necessarily thick like.

- Q:Reason: my house top floor lovers afraid of leaking to want to shop a large area of aluminum plate, but after all, is the right angle of the aluminum plate is really hurt, they want to install a 120 wide gypsum line landscaping the following, I would like to ask how to install gypsum board gypsum Line, firm, pvc gypsum line is good, or gypsum material gypsum line is good, thank you

- Generally worried about the water, aluminum buckle plate is not good to see around the dry aluminum or plastic plate or aluminum plate, the middle of the aluminum plate

- Q:The designer advised us to use the gypsum board on the toilet, said nice, the atmosphere. Because we are in the top floor, does not affect the leakage, we first decoration, good tangled, such as gypsum board, then the cost will be much higher? Please experts to give advice.

- I was decorating, the bathroom ceiling never used gypsum board, the bathroom water vapor weight, gypsum board will suffer after damp

- Q:What are the properties of aluminum?

- Aluminum reflection of the light is also very good, reflective UV than silver, aluminum more pure, the better the ability to reflect, it is often used to create high-quality mirrors, such as solar cookers and so on.

- Q:Interior decoration often use the strip of aluminum slabs have any specifications of the profile. Often the market is how long and how long to sell? Thank you! The The Usually the kitchen, bathroom, corridor ceiling with.

- Metal (aluminum slab plate) ceiling in recent years only appeared and popular, it has become the darling of the kitchen darling. Compared with the traditional materials, metal ceiling with elegant color and diverse, three-dimensional sense of strong, decorative effect, and other decorative materials, such as tiles, marble, etc. can form a very coordinated overall decorative effect. Metal ceiling fire, waterproof performance, light material, high strength, easy aging, easy installation, with good sound absorption, sound insulation performance, as well as easy to clean fume, long life, easy deformation and other advantages. Specifications: width: 100 200 300 mm thick: 0.6 ~ 1.0 mm long: 600 ~ 1200 (the family for the length, but also the length of processing)

- Q:Can the ceiling of the balcony be used? My house is on the top floor, the balcony ceiling is glass. With aluminum cords hanging ceiling summer high temperature buckle plate will not deformation ah?

- Can be used is the aluminum plate will be more hot aluminum is not insulated

- Q:The top of the kitchen is decorated with an aluminum plate or a good gypsum board

- Kitchen bathroom should be used aluminum plate, that is, integrated ceiling! Aluminum is suitable for the kitchen is not beautiful, the greater use is anti-fumes, pollution, corrosion, easy to clean up! Toilet selection integrated ceiling is the best choice for the internal space, waterproof and strong, for the toilet bath and other electrical operation to provide better protection!

- Q:What should I pay attention to when buying an aluminum plate?

- 1, aluminum plate quality is not good in its thick thickness, but rather the texture of aluminum. Some of the no-name products are used in the aluminum cans, because the aluminum is not good, the board can not be evenly thin, can only do some thick. To prevent bad businessmen deliberately deceive, not thick aluminum plate on a certain quality. 2, home decoration with aluminum plate thickness of 0.6 mm is enough to use, because home improvement with the aluminum plate, the length of less than 4 meters, and there is no heavy furniture on the ceiling. Only in the project with the aluminum plate will be longer, which is mainly to prevent deformation, so use thicker (0.8 mm above), the hardness of some of the aluminum plate. 3, take a sample beat a few times, if the sound is brittle, indicating that the product substrate is good; if the sound boring, indicating that the product more impurities. 4, take a sample repeatedly broken off to see if it is off the paint, from the skin. If it is a good quality aluminum plate, the paint will only crack, there will not be large pieces of paint off. Good aluminum slabs are on the back of the paint, because the back of the environment is generally more humid, with lacquered aluminum slab plate life than only single-sided aluminum slab longer. 5, to prevent the business "gnawing column." Coated film and roller coating from the appearance of the difference is not good, but the price is very different.To prevent some bad business to take roller coated board plaster board, available lighter will Board blackened, covered with easy to wipe the black stains, and rolling board no matter how rub will leave traces. 6, aluminum buckle keel material is generally galvanized steel, to see its flatness, the degree of smooth processing, keel the higher the accuracy, the better the quality.

- Q:Who has CAD - 600 * 600 mineral wool board ceiling 300 * 300 aluminum slab plate ceiling node map urgent use

- Generally used in the kitchen bathroom, the use of the most important concern is the effect of oil and water. Aluminum slab plate, especially the roller coating of the durability effect is better mineral wool sheet is mainly used in the engineering market. Such as public places, large public places. This kind of place is relatively important for the fire function. For this aspect more value. The use of different categories, you have to choose according to the specific purpose of use.

- Q:What is the size of the integrated ceiling plate?

- Home improvement, there are two places to consider the installation of aluminum buckle ceiling, one bathroom, one kitchen, then, the choice of aluminum buckle ceiling will take into account.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Best Quality Aluminum Ceiling China Supplier

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords