Best Price For Aluzinc Steel Coil-JIS G3321

- Loading Port:

- China Main Port

- Payment Terms:

- T/T or L/C

- Min Order Qty:

- 25mt m.t.

- Supply Capability:

- 5000mt/per month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

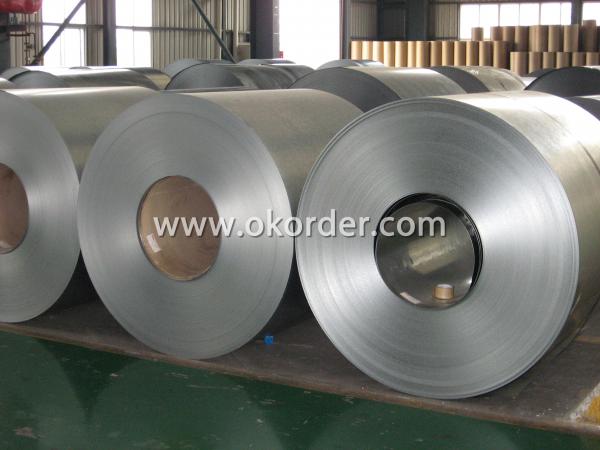

General Information Of Aluzinc Steel Coil JIS G3321

With Cold Rolled Steel as base metal,with the aluzinc coated, finally the plate steel is called galvalume steel. Galvalume steel is good capable of decoration, molding, corrosion resistance. It generally displays superior workability, durability and weather resistance.

|

Thickness 0.25-4.0mm (BMT) |

|

Aluzinc Coating 50-150g/m2 |

|

Width 900-1250mm |

|

Internal Diameter 508mm or 610mm |

|

Coil Weight 4-8MT |

|

Quality Commercial and structural quality |

|

Surface Treatment Oiled or Dry, Chromated, Anti-finger,Non-skinpass,/ Skinpass |

|

Standard JIS G 3321, ASTM A792M, EN 10215 |

|

Base Steel Grade SGCC,SGCD,DX51D+Z,DX52D+Z;S200GD,S220GD, S280GD,S350GD,CS,FS,SS |

Chemical Composition Of Aluzinc Steel Coil JIS G3321

|

C |

Si |

Mn |

P |

S |

|

0.04-0.06% |

0.01-0.03% |

0.18-0.22% |

0.014-0.016% |

0.006%-0.009% |

Technical Data Of Aluzinc Steel Coil JIS G3321

|

Yield Strength |

(Mpa) 280-320 |

|

Tensile Strength |

(Mpa) 340-390 |

|

Elongation |

20%-30% |

|

Out- of-Square |

Not exceed 1% Flatness |

|

Bow |

15mm max |

|

Edge Wave |

9mm max |

|

Centre Buckle |

8mm max |

|

Bending At 180 Degree |

No crack, purling and fraction |

Application Of Aluzinc Steel Coil JIS G3321

Aluzinc Steel can be widely used in transportation, light industry, civil usage and farming. It is also the perfect building material in construction for making roofing tile, steel profiles for wall partition, T-bar, studs, fireproof door, air conditioning duct and home appliances.

Packaging & Delivery Of Aluzinc Steel Coil JIS G3321

Full wrapped with anti-damped paper inside, iron sheet wrapped outside, and bundled with iron strips.

- Q:I've created something but it's a huge secret. Anyways I need to know everything and anything about steel. Like the iron steel. ANYTHING AND EVERYTHING. Best answer goes to the person with the most correct information. Please this is really important.

- If you want to know everything about steel, there's no way you're going to get an answer on Yahoo that is comprehensive enough. What you want to do is get some books on steel metallurgy, engineering properties of materials, and maybe machine design depending on your application. Topics will include molecular structure, material properties, alloying, stress and strain, work hardening, creep, computing damage and lifetime cycles, corrosion, toughness vs hardness, heat treating, and a ton of others. If you want to sharpen steel, that is a whole topic in itself concerning different blade profiles and their sharpness, edge holding, ease of sharpening, type of grind etc.

- Q:Can steel coils be coated with ceramic?

- Yes, steel coils can be coated with ceramic. Ceramic coatings provide a protective layer that enhances the corrosion resistance, heat resistance, and durability of the steel coils. Additionally, ceramic coatings can also offer improved electrical insulation and thermal barrier properties.

- Q:How do steel coils contribute to seismic resistance in structures?

- Steel coils contribute to seismic resistance in structures by providing strength and flexibility. The coiled shape allows the steel to absorb and dissipate the energy generated during seismic events, thereby reducing the impact on the structure. This increased flexibility helps prevent the structure from collapsing under the stress of seismic forces, making it more resistant to earthquakes.

- Q:How do steel coils contribute to the circular economy?

- The recyclability and reusability of steel coils make them valuable contributors to the circular economy. The main goal of the circular economy is to minimize waste and promote the continuous use of resources, and steel coils align perfectly with this concept. To begin with, steel coils are manufactured using recycled steel, which reduces the need for extracting raw materials and the associated negative environmental effects. By utilizing recycled steel, we can conserve natural resources and decrease energy consumption in the manufacturing process. This practice not only lowers carbon emissions but also decreases the overall ecological footprint. Furthermore, steel coils can be easily recycled once they reach the end of their lifespan. Steel has one of the highest recycling rates globally. When the coils are no longer in use, they can be collected, processed, and transformed into new steel products without losing their properties or quality. This closed-loop recycling system ensures that steel resources are continuously utilized, reducing the need for virgin steel production. In addition, steel coils support the circular economy by enabling the production of durable and long-lasting products. Steel is renowned for its strength and durability, making it ideal for various applications such as construction, automotive, and packaging. By using steel coils, we can manufacture products with extended lifespans, minimizing the need for frequent replacements and reducing waste generation. Moreover, steel coils can be reused multiple times before being recycled. They can be rewound, reshaped, or repurposed for different applications, thus extending their lifecycle and reducing the demand for new coils. This aspect of reusability contributes to resource efficiency and waste reduction. To summarize, steel coils play a significant role in the circular economy by being made from recycled steel, easily recyclable themselves, enabling the production of durable products, and promoting reuse. Their contribution helps close the loop in the steel industry, conserves natural resources, reduces waste generation, and minimizes environmental impact.

- Q:I am doing a project on how revolvers work and what materials they use and would like to know what specific grade of stainless steel they use for the manufacturing of the frame and cylinder?

- *Rifle barrels are usually made from steel alloys called ordinance steel, nickel steel, chrome-molybdenum steel, or stainless steel, depending upon the requirements of the cartridge for which they are chambered. The higher the pressure and velocity of a cartridge (pressure and velocity usually go up together), the faster it will wear out a barrel. To give a satisfactory service life, barrels for high velocity cartridges must me made from tougher and harder steel than barrels for lower pressure cartridges. *The 400 (416) series SS commonly known as ordnance grade , is what barrels are made from . *If you want your barrel to be made from super alloy then it is 718 Inconel ,but a costly affair.

- Q:What are the environmental impacts of steel coil production?

- The environmental impacts of steel coil production include emissions of greenhouse gases, such as carbon dioxide, during the process of extracting and processing raw materials like iron ore and coal. Additionally, the production of steel coils requires a significant amount of energy, contributing to the depletion of natural resources and increased carbon emissions. The wastewater generated during steel production can also contain pollutants, which may harm aquatic ecosystems if not properly treated. Furthermore, the disposal of steel coil waste, such as slag and other by-products, can pose challenges in terms of proper handling and potential contamination of soil and water sources. Overall, steel coil production has substantial environmental impacts that demand sustainable practices and mitigation measures.

- Q:How are steel coils used in the production of steel chains?

- Steel coils are used in the production of steel chains by being unwound and fed into a machine that shapes and forms the individual links of the chain. The steel coils provide the raw material needed to create the strong and durable chains, ensuring they have the necessary strength and integrity for various applications.

- Q:So we all know a 1000lb steel ball will sink in water, but if you were to leave the center of the ball hollow and fill with air, if the steel ball was big enough in diameter it should float correct? What size would the steel ball need to be to float?

- sure, if the volume of air is about 7 times the volume of steel, the specific weight of the steel/air system would be below 1.0 and it will float. How do you think ships float?

- Q:How do steel coils contribute to the agricultural machinery industry?

- Steel coils are an essential component in the manufacturing of agricultural machinery as they are used to create durable and robust parts such as frames, chassis, and components. The high strength and versatility of steel coils ensure that agricultural machinery can withstand harsh conditions and heavy usage, providing reliability and longevity to farmers and the industry as a whole.

- Q:What is the average lifespan of a steel coil?

- Several factors can influence the average lifespan of a steel coil. These factors encompass the quality and type of steel utilized, the conditions in which the coil is stored or used, and the maintenance and care it receives. Typically, a steel coil that is well-maintained can endure for approximately 10 to 30 years. Nevertheless, this is merely an approximation, and the actual lifespan can be either shorter or longer depending on the aforementioned factors. For example, if the coil is exposed to severe environmental conditions, such as extreme temperatures or corrosive elements, its lifespan may be diminished. Regular upkeep and proper storage can significantly prolong the longevity of a steel coil. This entails ensuring that the coil is stored in a dry and safeguarded environment, frequently inspecting and addressing any indications of corrosion or damage, and conducting routine cleaning and lubrication as necessary. Ultimately, the average lifespan of a steel coil is contingent upon various factors, and it is advisable to consult the manufacturer or industry experts for a more precise estimation based on specific circumstances and conditions.

1. Manufacturer Overview |

|

|---|---|

| Location | Zhejiang, China |

| Year Established | 1999 |

| Annual Output Value | US$1 Million - US$2.5 Million |

| Main Markets | Europe; Africa; Mid East; Southeast Asia |

| Company Certifications | ISO9001;ISO14001 |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Shanghai Port |

| Export Percentage | 41% - 50% |

| No.of Employees in Trade Department | 50-80 |

| Language Spoken: | Chinese, English |

| b)Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | 5 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | Average |

Send your message to us

Best Price For Aluzinc Steel Coil-JIS G3321

- Loading Port:

- China Main Port

- Payment Terms:

- T/T or L/C

- Min Order Qty:

- 25mt m.t.

- Supply Capability:

- 5000mt/per month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords