Best Heat Insulation Ceramic Fiber Blanket HZ

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Information of Ceramic Fiber Blanket

CMAX ceramic fiber blanket is made from high quality Gao-Ling clay, high purity alumina and silica oxides by spun or blown process. It is asbestos free. Double-side needling provides blanket with great tensile or handing strength for easy installation.

The products are classified as STD, HP, HA, and HZ respectively corresponding to different maximum service temperature 1000℃,1100℃,1200℃ and 1350℃

Feature of Ceramic Fiber Blanket

Heat resistance

Light weight

Low thermal conductivity

Low heat storage

Resilient to thermal shock

High tensile strength

Application of Ceramic Fiber Blanket

Petrochemical process heater refractory fiber lining

Heat treating furnace or Intermittent(shuttle) kiln hot face lining

General furnace backup insulation

Heat seals for kiln car or furnace door

Electrical insulator

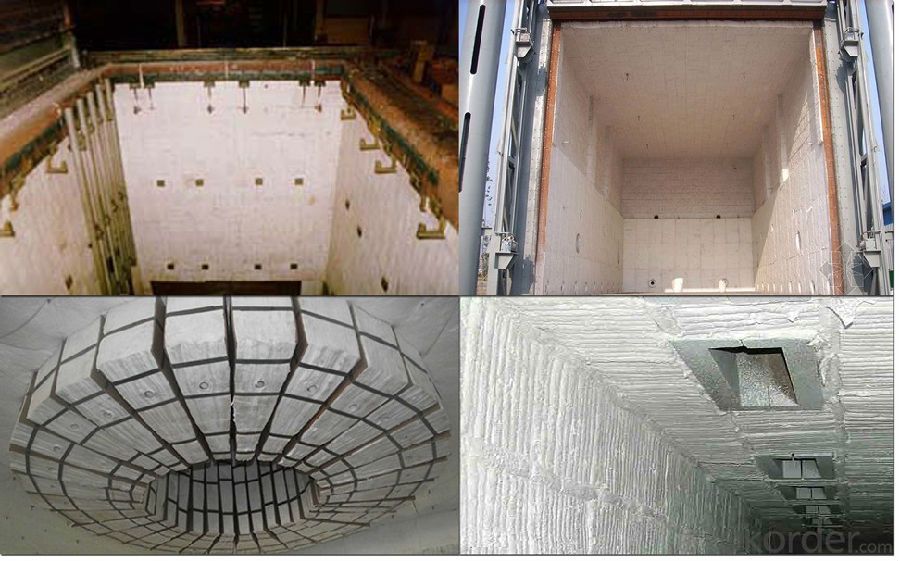

Picture of Ceramic Fiber Blanket

FAQ

1. Which products do you have?

We have all kinds of refractory brick, castable, mortar, cement, ceramic fiber products, etc.

Or you could browse our products to choose what you need.

2. How do you control the products quality?

With strict quality control system throughout the materials selection and production process, our refractory and ceramic fiber products quality is effectively controlled to meet customer requirements.

From the raw materials selecting, our quality control begin. The quality certificates of raw materials are required and each batch will be tested before using. During production, the quality control are conducted by workers and then each piece will be sorted and examined by quality supervise.

3. Can you give me a brief introduction of the application of your products?

We are mainly specializing in the refractory materials in iron and steel, cement, glass, ceramics, petrochemical, electric power Industry, etc.

4. If I need your offer, what information do you need?

In order to choose suitable products, it will be appreciated to provide us the information, such us specification, technical data, order quantity, products application etc.

If any question, please contact us freely.

- Q:I have an American knitting pattern which calls for sport weight yarn, I cant find what that is in the UK, can anyone help.

- Sport weight yarn is a fine weight of yarn used for knitting and crochet projectsSport yarn is also sometimes called double knitting (DK)It's the third thinnest yarn after lace and baby weight yarns and just under worsted in thicknessSport weight yarn is knitted with medium sized knitting needles and crocheted with a medium sized crochet hookThere are many different kinds of sport weight yarns including acrylic, cotton and alpaca Sport yarn isn't named after anything having to do with athletics, but rather its name refers to the thickness of knitted or crocheted material it createsThe thickness of garments knitted with sport weight yarn is considered similar to the fabric associated with women's sportswearSport weight yarn is a popular yarn for creating lightweight, thinner sweatersThe website below breaks it down, how the yarns are weighed and categorized it of course has to do with twists per inch and thickness but is a good tool to figure out what you want I would like a red and green hat with a tassle on top please

- Q:I am totally smitten with cashmere, all types of sweaters, pillows, pants, shawls, blanketsI just love 100% cashmere, there's nothing that's as soft! Am I crazy for loving a fiber so much? If you feel the same, which company do you think makes the best cashmere? I'd have to say it's a tie between TSE and Pure Collection (UK)Am I alone here?

- oooh i love italian cashmere! i just have to have a cashmere cardigan in every color!

- Q:well, i mean like make fabrics or a kind of felt? or maybe even yarn?i mean, we use animal hair, and we use chemicals that give people allergic reactions as fiberswe even wear plastic and nylon on occasion, so i really do not thin it is a quot;yukquot; factorwell, we go to the barber and we see hair everywhereall over the floorslong and shorti know we use it sometimes for wigs, but we got a ton of extra hair on the floor, i do not know how much, but it is a lotso why do we not make things likd fabric, yarn and/or felt with human hair?(ONLY FROM THE TOP OF THE HEAD, no groin hair, maybe beard hair if long enough)

- OatmealRaw veggies (broccoli, cauliflower)Apples.

- Q:I have a home built Yagi antenna, and for the 5 elements on it I used 14 guage copper wire (stranded) (I am not using high wattage)Do I need to strip the insulation from the copper wire for the antenna to function? (as you might have guessed, it is not).

- Probably just dry skin is causing tthe peeling try using baby lotion twice a day that should helpAs for the bubblss id be very concerned about thisDoes not sound normal to me at allIve never even heard of this happeningm definateky have ur baby checked out by a pediatrition/doctor asapI personally would take baby to the emergHope bubbs is better soon

- Q:I just want it to be higher so that I don't get fat or anything like thatI'm 13 sooooois there anything I can eat/drink that'll help?

- 1WaterWater suppresses hunger and speeds up weight loss, and has no calories2Green TeaStudies show that green tea extracts boost metabolism and may aid in weight lossThis mood-enhancing tea has also been reported to contain anti-cancer properties and help prevent heart disease3SoupEat less and burn fat faster by having a bowl of soup as an appetizer or a snack4GrapefruitGrapefruit boosts metabolism and is great for you too5Apples and Pears! Fruit keeps you full longer, speeds up weight loss, and fulfills your sugar cravings6BroccoliStudy after study links calcium and weight lossBroccoli is not only high in calcium, but also loaded with vitamin C, which boosts calcium absorption7Low-Fat YogurtDairy products can boost weight loss efforts, and yogurt has plenty of other nutrients without the calories8Lean Turkey! Countless studies have shown that protein can help boost metabolism, lose fat and build lean muscle tissue so you burn more caloriesInstead of fatty beef, turkey is a great meat9OatmealThis heart-healthy favorite ranks high on the good carb list, because it’s a good source of cholesterol-fighting, fat-soluble fiber that keeps you full and provides you with the energy you need to make the most of your workouts10Hot PeppersEating hot peppers can speed up and boost metabolism and cool your cravings, due to Capsaicin (a chemical found in jalapeno and cayenne peppers).

- Q:How is the quality of ceramic fiber vermiculite cloth?

- The quality is good. The refractory temperature of ceramic fiber vermiculite cloth is 1200-1450 degree. Ceramic fiber is a kind of fibrous lightweight refractory material with light weight, high temperature resistance, good thermal stability, low thermal conductivity, low specific heat and mechanical shock resistance and other advantages, so it is widely applied in industries such as machinery, metallurgy, chemical engineering, petroleum, ceramics, glass and electronics.

- Q:For the past 3-4 months, I have been eating alot healthierBut, since fiber is really filling and satisfying, it's been my best friendIt hasn't been uncommon for me to have 4 apples, 2 oranges, plain popcorn, a large salad, high fiber cereal, sprouted whole grain bread, Kashi Granola bars, oatmeal, peanut butter, and multigrain pasta all in one dayLet me tell you thats alot of fiberIt hasn't affected my digestion at allWhy is that? Everyone else on here is like quot;if I eat 2 apples a day, will that be healthy?quot; and all the answers are like quot;Yeah, but you'll be spending lots of time in the bathroom.quot; What's wrong with me??? Like, I go a normal amount, but shouldn't it be alot more?

- For that price I'd definitely go usedYou won't be able to find a good new guitar in that price rangeYou may find one that you like at first, but if you get serious about playing at all you'll want to upgrade really soonLike others said try craiglist, OKorder, or check out used instruments at local guitar stores.

- Q:I've finally decided I need to make the transition from natural to straight hair (I wear my hair in braids all the time)As such, I think that since I work out a lot, I need to straighten it with a relaxerHowever, I was wondering if using a relaxer and a high quality flat-iron like the Solia would be too damaging to my hair (I only plan to use the flat iron 2x a week at most)If I wash my hair weekly, would that be bad, too? Help a sister out, please! :)

- runescape is beautiful addicting and that i play it any time i willplenty of humans say its a dull recreation however i attempted it as soon as and that i adored it and ive been gambling for a million.five year and that i nonetheless addicted if you're bored in coaching a ability on runescape a well recreation to play to kill time is snowball 2008 seek that during google and click on the primary effector LineRiderthat may be hilarious.

- Q:If so, congratulations, keep up the good workIf not, what's the plan for next week? I lost three pounds this week and am 6 and a half pounds from my target weight, which I achieved in 2005Its been a bit of a struggle at this pointIt seems to get harder, the closer it getsMy incentive is, ?4.50 per week which I have to pay my slimming clubTarget members dont payMy danger period is evenings, in which I tend to snack and nibbleWhat is your danger period and how do you overcome the urge to eat?

- Use your imaginationThe mind is a portal to an infinity of worldsRead good old science fictionGet the Star Trek series of DVDs, including the original (quaint, but excellent for its time), The Next Generation, Deep Space Nine, Voyager, and EnterpriseNetflix has them all, which would be prohibitively expensive to buy.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Best Heat Insulation Ceramic Fiber Blanket HZ

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords