Best Composites Fiberglass Products FRP Grating

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction

FRP Molded Grating is a structural panel which uses high-strength E-Glass roving as reinforcing material, thermosetting resin as matrix and then casted and formed in a special metal mold. It provides properties of light weight, high strength, corrosion resistance, fire resistance and anti-skid. FRP Molded Grating is widely used in oil industry, power engineering, water & waste water treatment, ocean survey as working floor, stair tread, trench cover, etc. and is an ideal loading frame for corrosion circumstances.

Feature

Corrosion Resistance

Fire Resistance

Light Weight & High Strength

Safety & Anti-slip

Electrical Insulating

Aging Resistance

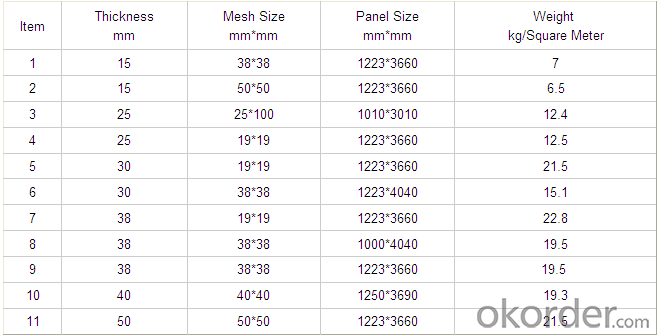

Specification

Advantage

coated with prevent aging layer

excellent insulating performance

no maintenance

high strength

long service life

easy installation

Application

Power plants, substation equipment enclosures, antimagnetic, anti-static,to prevent small animals into the equipment failure, as there is electricity facilities and without power interval intervals.

In high voltage electrical equipment for power line work, in order to prevent workers go wrong location, charged interval or near electrically charged equipment to dangerous distance.

Pool railings in sewage treatment industry

Corrosive chemical industry equipment around the fence

All kinds of building maintenance section

FAQ

1. How about the documents after shipment?

After shipment, we ll send all original documents to you by DHL, including Packing List.Commercial Invoice, B/L, and other certificates as required by clients.

2. How long is the delivery time?

Usually it takes 10-25days after receipt of the deposits or L/C, and it also depends on the quantity of your order.

3. How's the payment?

Telegraphic Transfer(T/T) or Letter of Credit(L/C)

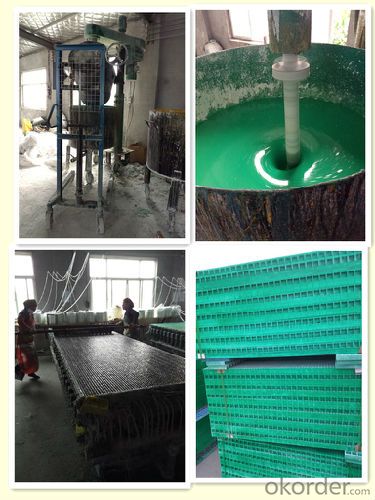

PROCESS

FACTORY

- Q:What does fiberglass reinforced composite PPR pipe mean?

- Is the pure plastic PPR pipeline on the basis of increase among the middle layer mixture layer of glass fiber and PPR, and the layer after pipe rigidity enhancement can reduce the use of pipe, pipe, oxygen, light and better performance, the pipeline to avoid bacteria.

- Q:Is there any way to do this without dry cleaning?

- i'm not taking any responsibility here for damage if this doesn't work but polyester washes perfectly well in the washing machine. or try some stain spot removal which you can get from a supermarket. read the instructions. or get a lightly damp cloth and just try rubbing off whatever it is you're trying to remove. wear a bib! ;)

- Q:If I were to run around in a white fur coat indoors and out I would be filthy in a matter of hours not to mention the weeks between baths my dog gets. I‘ve had a couple of dogs with white fur and day to day activities don‘t ever seem to make it look dirty (there are of course the romps in mud that require an immediate bath -but that isn‘t what I‘m talking about). If anything I would expect their fur to get dirty quicker than our hair. But I couldn‘t go three days without a shampoo with out looking noticeably dirty, the dog can look clean for weeks!

- Normally, dogs with white coats have that color for a reason. Herding dogs need the coat in order to be able to hide with the sheep and not upset them. Most white coats are coarse, and are more than one layer. The outer layer sheds dirt and water and the inner layer keeps the dog warm or shields them from the heat. It really is amazing to see how clean most white coated dogs are, regardless of being in or out of the house. My collies and shelties white fur is always snow white.

- Q:Which is better, basketball shirt mesh and polyester cloth?

- Personal comparison of polyester, mesh of a sweat attached to the body, especially uncomfortable

- Q:i am looking for some comfortable boardshorts that the water damn near rolls off of. i saw a pair of affliction boardshorts (unfortunately they were a couple sizes too big) that was a 80/20 polyester/spandex material that seemed to be what i was looking for. anybody here an expert on board shorts, or cloth?

- Nylon! Competitive swimmers swim in techincial suits that are made of these three materials: NYLON, SPANDEX, and LYCRA!

- Q:I bought a dress that is polyester/spandex. While I love the dress, I hate the pleats. The pleats seem to be pressed not sewn in, but i dont want to chance it and ruin the dress. Is it something I can try myself or should I just deal?

- Depending on the pleats and how long they are you might try experimenting with white vinegar, a hot (as hot as the material will take) iron with steam and a pressing clothdo this from the wrong side in an inconspicuous spot firstBy the way, it is very smelly but the smell will dissipate

- Q:Ask the Tianli pipe what are the advantages?

- Then they in the process of processing, is the artistic creation, such as its yellow green PP-R nano antibacterial tube, pipe, tube and other fine green glass, are functional.

- Q:How much waterproof one square metre toilet leak how to do?

- The "eternal" brand super waterproof agent *20 kg / barrel: such as mortar waterproof agent, waterproof layer 10mm, a barrel construction of 8 square meters; such as single component cement, 0.8-1.2 kg / m2 / barrel layer, construction of 40 square meters, the price is about 198 yuan / barrel. Wait

- Q:Does cleaning laptop screen daily will end the screen life shorter?

- if you do it correctly, then it should not. use diluted vinegar and water, use straight lines, no circles, and then dry. do this with power off.

- Q:If I wanted to use some kind of cloth,like kevlar,aramid,or something of the sort to make a speaker cone,what kind of resin would be best to combine with it?I‘ve heard of poly-glass,but what is that?when I look it up,it‘s like it doesn‘t exist.Or how bout a pour on polymer hard epoxy resin?Or would epoxies crack?Or what about polyester resins? And whats the difference between those kinds and regular fiberglass resin?I know epoxy dries harder,but is it really that much harder?which would be better for what I want to do?And where can I find it?Thanks a lot!!

- Search it on google [:

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Best Composites Fiberglass Products FRP Grating

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords