Bearings single row tapered roller, model 32048

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50000 pc

- Supply Capability:

- 1000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

- Single row Tapered roller bearings

Single row roller bearings can only bear the shaft or shell of a direction of the axial

displacement and a direction of the axial load. So we need the two bearing face to face or

back to back to use.

★Product features

The inner and outer ring raceways are segments of cones and the rollers are also made with a taper so that the conical surfaces of the

raceways and the roller axes if projected, would all meet at a common point on the main axis of the bearing. The rollers are guided by a

flange on the inner ring. This stops the rollers from sliding out at high speed due to their momentum. The larger the half angles of these

cones the larger the axial force that the bearing can sustain.

★Product application

In many applications tapered roller bearings are used in back-to-back pairs so that axial

forces can be supported equally in either direction.

Pairs of tapered roller bearings are used in:

- car and vehicle wheel

- mining equipment

- moderate speed

- engine motors

- axle systems

- construction

- agriculture

- reducers

- gear box

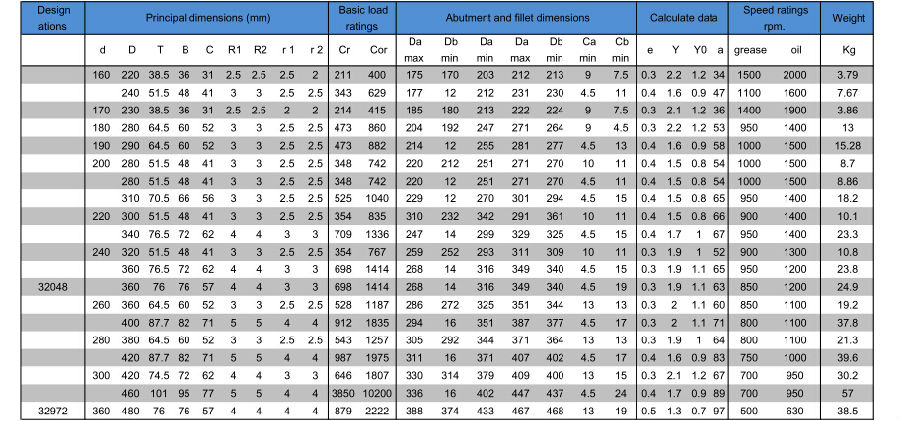

★Horton tapered roller bearings Basic size

- Single row tapered roller bearings:

Inner ring size: 20mm ~ 1270mm Outer ring size: 40mm ~ 1460mm Width size: 15mm ~ 240mm

- Double row tapered roller bearings:

Inner ring size: 38mm ~ 1560mm Outer ring size: 70mm ~ 1800mm Width size: 50mm ~ 460mm

- Four row tapered roller bearings:

Inner ring size: 130mm ~ 1600mm Outer ring size: 200mm ~ 2000mm Width size: 510mm ~ 1150mm

★Tolerance:

Horton tapered roller bearing with common

tolerance, and also provides P6X, P6, P5, P4,

★Radial clearance

Horton single row tapered roller bearings only

in after installation have clearance, and in

★Cage

Tapered roller bearing general ues the steel plate stamping, basket shape cage, but when the size is bigger, we

also adopts entity cage.

1. Outside diameter D ≤ 650mm, use the steel plate stamping cage, cage postposition without code mark.

2. Outside diameter D > 650 mm, use the steel entity prop cage, cage postposition without code mark.

★Dynamic equivalent load

P = Fr [KN], Fa / Fr ≤ e;

P = 0.4Fr + YFa [KN], Fa / Fr > e.

The single row tapered roller bearings used in pairs (basic physical size can be different), when calculation the

equivalent dynamic load of the bearing, must be included in the radial load cause additional axial force. The single

row tapered roller bearing additional axial force S, can approximate formula: S = Fr / 2y

★Static equivalent load

Single row tapered roller bearings

P0 = 0.5Fr + Y0Fa [KN] P0 < Fr, then P0 = Fr

Double row tapered roller bearings

P = 0Fr + Y1Fa [KN],Fa/Fre ≤e P = 0.67Fr + Y2Fa [KN], Fa/Fre > e

- Q:Online cylinder cones are GB/T4663, what do you mean?

- Which size do you want, eldest brother? How do I make so much?GB/T: recommended national standards; GB: mandatory national standards4663: taper roller national standard codeThere is a missing release year later!It should be: GB/T 4663-1994

- Q:What are the E and Y values of the 30209 bearings of tapered roller bearings?

- The shoulder of the positioning shaft is positioned; the transition shaft shoulder is provided for the disassembly of the parts on the shaft or the prevention of the stress concentration. But the axial shoulder will inevitably increase the diameter of the shaft, and the shoulder of the axle will change due to the stress concentration.

- Q:Can tapered roller bearings be installed in a vertical direction? In a vertical direction rather than in a horizontal direction..

- Absolutely. The bearing below the figure is the tapered roller bearing placed vertically.

- Q:you master good! Ask a question about the use of tapered roller bearings: a mechanism using a double row tapered roller bearings, but did not buy this model, can use two single row tapered roller bearing together instead of double row?

- 2, the clamping way is: double row bearing inner ring is double row, or outer ring double, determines when you install the inner ring or outer ring is clamped, clamped, if you want to replace with the two row, when combined with the clearance you need to consider the ring, you should adjust the clearance and is placed on the inner ring, or on the outside, too that depends on your way of clamping;

- Q:What items should be inspected for tapered bearings?

- 2, tapered roller bearings are not allowed to have an electric drill pattern, vibration patterns, yin and Yang face and polished traces, did not promise to emerge supporting construction and obvious measurement traces, did not agree to knock bumps and obvious color difference.3, the name of the whole machine did not promise to have oxide skin.

- Q:Tapered roller bearings, 70 in diameter, please tell me the model number

- What about outside diameter (D) and width (B)? You didn't say?.Following are all series of codes and sizes for tapered roller bearings (single column and double row). I hope they can help.Single row tapered roller bearings (taken from GB/T 297-1994)Bearing code |30000: 32914 X2Basic size /mm|d: 70Basic dimensions /mm| D: 100Basic size /mm|T: 20Basic size /mm|B: 19Basic size /mm|C: 16Installation size /mm|da (min):-Installation size /mm|db (max):-Installation dimension /mm| Da (min):-Installation size /mm|Da (max):-Installation size /mm|Db (min):-Installation size /mm|a1 (min): 4Installation size /mm|a2 (min): 6Installation size /mm|ra (max): 1Installation size /mm|rb (max): 1The other is /mm|a size: 19Other sizes /mm|r (min): 1Other sizes /mm|r1 (min): 1The calculated coefficient is |e: 0.33The calculated coefficient is |Y: 1.8The calculated coefficient is |Y0: 1Basic rated load /kN|Cr: 53.2Basic rated load /kN|C0r: 85.5The speed limit / (r/min) | fat: 3600The speed limit / (r/min) | oil: 4500The weight is /kg|W:-

- Q:Is the tapered roller bearing so correct?

- Tapered roller bearingTapered roller bearings are designed for the inner ring, outer ring raceway and roller cone vertex on the central axis of the bearing, radial load acting on the bearing, axial force is generated. Therefore, it is necessary to use the 2 bearings for use, or as double pairs of bearings, double row bearings. Combination and double row tapered roller bearings, when radial loads act on tapered roller bearings

- Q:Tapered roller bearing suffix code YA2 stands for what does that mean?

- SatisfyHappiness is merely material meet? Of course not, happiness is not simple and get food and drink happy nor personal desires superficial meet. Wealth has sometimes not happy, luxury, and happiness cannot lead a gay life equate. Therefore, the material does not meet the real happiness.It is the balance of happiness tends to meet the spirit of Confucius, "there are friends from afar" or "awfully";

- Q:Taper roller bearings are used on my motor. Serious damage occurred during use. Please help me analyze the possible causes of damage! Thank you

- But it is worth noting that you must control your parts tolerances, affect the tolerance of your variables clearance values are 11, 1 respectively -- bearing outer ring end face of large tolerances; 1 large end bearing inner ring outer ring end face 2 large tolerances; tolerances of bearings; 2 large end face of the inner face of tolerance between the two bearings, bearing; the small ring thickness tolerances; spacer ring tolerances; axial length tolerances; and two bearing diameter tolerances, and the corresponding axis tolerances (same axis but not at the same time processing is considered as two independent variables), consider the last four variables is because of you this application should be tightly matched with the inner ring, it will affect the clearance.

- Q:The installation of tapered roller bearings

- 1, for example, a shaft needs to be fitted with two such bearings at both ends. Can it be installed in the same direction?The force of the shaft is concerned. If the shaft is indeed subjected to one-way axial force, of course, it can be installed in the same direction. If it is subjected to biaxial axial force, it will not work

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Bearings single row tapered roller, model 32048

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50000 pc

- Supply Capability:

- 1000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords