Bearings four row cylindrical roller, model FC202870

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Bearings four row cylindrical roller, model FC202870

Four row cylindrical roller bearings

Four row cylindrical roller bearing is usually use in rolling mill’s work roll or back-up roll. It mainly take much radial load, which is extensively used on the work roll of wire rod mill, section mill and bloomer mill , as well as the back-up roll of dressing machine, cold rolling mill and hot rolling mill.There are three kinds of structures: FC, FCD, FCDP. There are three grades for tolerance : 0 , 6 , 5.

FC: double outer ring, single inner ring, inner ring without rid;

FCD: double outer ring, double inner ring, inner ring without rid;

FCDP:double outer ring, double inner ring, inner ring without rid

★ Product Features:

The rollers of the cylindrical roller bearing are usually guided by two flanges of a ring.

Because this assembly part composed of cage, roller and guide ring can be separated from

another ring, the cylindrical roller bearing belongs to separable bearing. This type of bearing

can be easily mounted and dismounted. Its advantages are obvious especially when there is

interference fits between the inner, outer ring and the axis, housing.

This bearing is usually subjected to radial load, only the single-row bearing with inner& outer

rings flanges can bear small steady axial load or great intermittent axial load. It has a high

requirement on the processing of the fitting parts such as axis and housing bore, etc.

★Product Application:

Cylindrical roller bearings are mainly used for:

- Iron and steel metallurgical industry

- medium and large motor

- generator

- combustion engines

- gas tuibine

- machine tool spindle

- speed reducer

- loading and unloading machinery and all kinds of industrial machinery

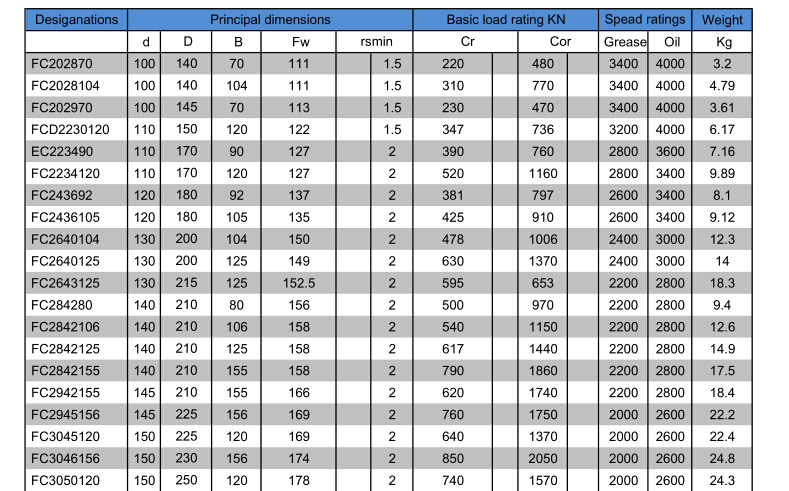

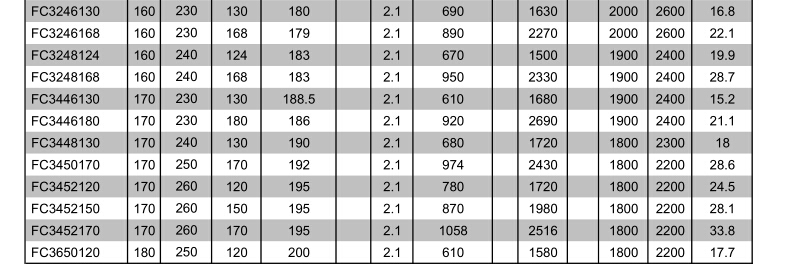

Four Cylindrical Roller Bearings Catalugue

- Q:Cylindrical roller bearings NUP2311E mounting dimensions: Da (max): 69Da (min): 64DB (min): 72DC (min): 80Da (max): 111What are the specific meanings of these dimensions? Thank you, master

- Da means shoulder diameter, that is to say, the maximum shoulder size is 69mm, and the minimum is 64mm

- Q:How should I find the concentricity of cylindrical roller bearings after installation?

- So, in the machining process, try to use special fixtures and parts drawing in tol and other measures to avoid such a remedy".

- Q:Why are cylindrical roller bearings suitable for traveling support?

- Should be the inner ring and the outer ring without the edge of the can do moving support. Cylindrical roller bearings without inner sides of the inner ring or outer ring, whose inner and outer rings can be moved relative to the axial direction, so they can be used as free end bearings.

- Q:My notes is the former has a taper hole on the cone position preload, the latter is a nut. But the online information seems a little different. Are the preload methods for two direction thrust angular contact bearings and angular contact ball bearings the same?

- Dissimilarity! The former is mainly used as the support of the shaft with larger load. The main prevention is the radial runout, which is usually used individually, so there is not much demand for the preload.

- Q:How to check the thrust cylindrical roller bearings?

- Bearing dimensions (or bearing samples) have "basic rated load (KN)", this column can be directly detected, in general, according to the use of appropriate multiplied by a (1.2~1.5) safety factor. In accordance with the requirements of the design manual, the equivalent load can be calculated (considering the speed, temperature, load and stability).

- Q:what does that mean? Please enlighten master, thank you.

- Cylindrical roller bearingN216E stands for the bearing retainer as a steel cageN216EM stands for the bearing holder as brass holderThe material of the cage is different (the structure that holds the roller in it for a long time)

- Q:For example, NU, NJ, N, RNU, NUP, NF, NO, NN, RN, what do you mean, who can tell me about that hero?

- NU outer ring, double retaining ring, inner ring without edgeNJ outer ring, double retaining ring, inner ring, single edge

- Q:Can you make it clear? I don't understand. Thank you for being here first.

- A rolling body is a short cylinder.The inner ring (or outer ring) of the bearing can be split.

- Q:Double row cylindrical roller bearings how to disassemble?

- If it is replaced, use the flame to heat it quickly under the conditions permitted!

- Q:NSK cylindrical roller bearings EW/EM series of differences and characteristics

- E international is called "reinforced type" load, also means to increase rolling bodyW international is called a steel cage

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Bearings four row cylindrical roller, model FC202870

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords