Bearing Bearings 7017 Angular contact ball bearings 7017 Angular contact ball bearing

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 500000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Sepcification:

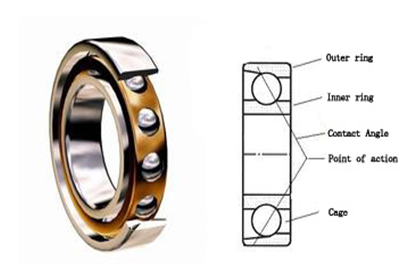

Angular contact ball bearings can bear radial load and axial load at the same time and also can bear pure axial load. Their ability of axial load is determined by contact angle and is increased with contact angle increasing; speed limit is higher; stiffness is big and can be pre-adjusted. They are applicable to high-speed and high-precision site.

Product application:

- spindle and other high speed precision mechanical spindle

- aircraft engine spindle

- high frequency motor

- printing machinery

- air compressor

- gas turbine

- jet engines

- turbines

-pump

| Design ations | Principal dimensions (mm) | 〆15º | 〆25º | ||||

| Limit speed | Limit speed | ||||||

| d | D | B | Basic load rating | Lubrication | Rated load | Lubrication | |

| Cr Cor | Grease Oil | Cr Cor | Grease Oil | ||||

| 70 Series single angular contact ball bearings | |||||||

| 7003 | 17 | 35 | 10 | 6.7 4.9 | 44000 66000 | 6.4 4.7 | 39000 59000 |

| 7004 | 20 | 42 | 12 | 9.6 6.3 | 37000 55000 | 9.2 6.0 | 33000 49000 |

| 7005 | 25 | 47 | 12 | 12.9 8.7 | 33000 49000 | 12.3 | 29000 44000 |

| 7006 | 30 | 55 | 13 | 15.7 11.6 | 27000 42000 | 14.9 10.9 | 23000 37000 |

| 7007 | 35 | 62 | 14 | 19.3 17.5 | 19000 33000 | 10.4 10.3 | 19000 33000 |

| 7008 | 40 | 68 | 15 | 19.9 19.1 | 18000 31000 | 18.9 18.2 | 16000 27000 |

| 7009 | 45 | 75 | 16 | 26.7 25.3 | 16000 27000 | 25.4 24.1 | 15000 25000 |

| 7010 | 50 | 80 | 16 | 27.6 27.5 | 15000 25000 | 26.2 26.2 | 14000 23000 |

| 7011 | 55 | 90 | 18 | 36.7 37.1 | 13000 21000 | 34.8 35.3 | 12000 19000 |

| 7012 | 60 | 95 | 18 | 37.8 | 13000 21000 | 35.8 38.0 | 11000 18000 |

| 7013 | 65 | 100 | 18 | 38.9 42.9 | 12000 19000 | 36.8 40.7 | 10000 17000 |

| 7014 | 70 | 110 | 20 | 49.9 55.5 | 11000 18000 | 47.2 52.7 | 9000 16000 |

| 7015 | 75 | 115 | 20 | 51.3 59.2 | 10000 17000 | 48.5 56.2 | 8500 15000 |

| 7016 | 80 | 125 | 22 | 61.6 70.4 | 9000 16000 | 58.3 66.9 | 8000 14000 |

| 7017 | 85 | 130 | 22 | 63.6 | 8500 15000 | 59.9 71.3 | 7500 13000 |

| 7018 | 90 | 140 | 24 | 66.9 | 8000 14000 | 63.2 79.7 | 7000 12000 |

| 7019 | 95 | 145 | 24 | 79.1 97.6 | 7500 13000 | 74.8 | 6500 11000 |

| 7020 | 100 | 150 | 24 | 81.2 103.3 | 7000 12000 | 76.7 | 6000 10000 |

| 7021 | 105 | 160 | 26 | 93.9 118.2 | 6500 11000 | 88.8 | 6000 10000 |

| 7022 | 110 | 170 | 28 | 110.4 139.8 | 6000 10000 | 104.4 132.8 | 5700 9000 |

| 7024 | 120 | 180 | 28 | 112.7 148.7 | 6000 10000 | 106.3 141.1 | 5700 9000 |

| 7026 | 130 | 200 | 33 | 144.8 190.8 | 5700 9000 | 136.8 181.0 | 5000 8000 |

| 7028 | 140 | 210 | 33 | 148.7 202.6 | 5000 8000 | 140.4 192.2 | 4600 7500 |

| 7030 | 150 | 225 | 35 | 168.4 232.5 | 4600 7500 | 159.1 220.6 | 4000 6500 |

| 7032 | 160 | 240 | 38 | 189.1 264.5 | 4000 6500 | 178.6 251.0 | 3800 6000 |

| 7034 | 170 | 260 | 42 | 205.6 299.3 | 3800 6000 | 194.2 284.0 | 3300 5300 |

| 7036 | 180 | 280 | 46 | 229.5 352.1 | 3500 5700 | 216.8 334.1 | 3000 5000 |

- Q:What is the selection principle of grease for plain bearings?

- 2. Selection of grease for sliding bearingsLoad 1-6.5MPa, shaft neck circumference speed below 1m/s, the maximum working temperature of 50-100 DEG C, the No. 2 lithium greaseLoad > 5MPa, journal circumferential speed 0.5m/s, maximum operating temperature 60 DEG C, roll No. 2 calender greaseThe load is less than 1MPa, the circumferential speed of the journal is below 1m/s, the maximum working temperature is 75 DEG C, and the No. 3 calcium base grease is usedLoad 1 - 6.5MPa, journal circumferential speed 0.5-5m/s, maximum operating temperature 55 DEG C, and use No. 2 calcium base greaseLoad > 6.5MPa, journal circumferential speed 0.5m/s below, maximum working temperature 75 DEG C, choose No. 3 calcium base greaseThe load is less than 6.5MPa, the shaft neck circumference speed 0.5-5m/s, maximum working temperature of 120 DEG C, the No. 2 lithium greaseLoad > 6.5MPa, journal circumferential speed 0.5m/s below, maximum working temperature 110 degrees, choose 2 calcium sodium base greaseCalcium base grease should be considered when the temperature is 75-120 degrees centigrade in humid environment;The working temperature should be below 75. The calcium base grease No. 3 should be considered. If not, the aluminum base grease can be used instead;The temperature at 110-120 DEG C, available barium grease or grease, lubrication, consistency to be smaller.

- Q:What is the effect of clearance on sliding bearings?

- Depending on the tolerance between the sleeve and the pin shaft with Jiashan lantalu Bearing Manufacturing Co. Ltd Sun Huaichen

- Q:How to determine the axial clearance and expansion clearance of plain bearings?

- 3. interference fit is the size of the hole when Kong Hezhou is matched, minus the size of the matched shaft, and the algebraic difference is negative. The interference fit is called interference fit. The tolerance of the hole at this time is below the tolerance band of the shaft. In the interference fit, as the size of the shaft is larger than the size of the hole, it is necessary to assemble under pressure or expansion or cold contraction. Interference fit is mainly used to fasten the relative movement between holes and shafts, such as the connection of gear ring and wheel hub of large gear.The 4. transition fit may be a gap or interference fit for the transition fit. At this point, the tolerance zone of the hole overlaps with the tolerance band of the shaft. The transition fit is mainly used for locating the connection between the shafts with good neutrality and coaxiality, and easy to disassemble and assemble, such as the connection between the inner diameter of the rolling bearings and the shaft.

- Q:Where are the upper plain bearings?

- or maintenance and lubrication of the difficult parts of the operation.For example cars on some copper sleeve, hydrostatic bearing = =

- Q:How is the axial clearance of plain bearings large?

- The sliding bearing has a barrel type, has several pieces of tile type, the barrel type general outer circle has the taper, adjusts the back cap to complete the gap adjustment, monolithic tile's general to a tile adjustment can eliminate the gap.

- Q:What are the tolerances and finishes for plain bearings and shaft mating surfaces?

- 1) the bearing and the shaft are matched with the base hole system, and the shaft shaft system is used to match the bearings and the housings.Bearing size tolerance and rotary accuracy shall be calculated according to GB307 - 84 corrosion resisting pump.2) the shaft neck and the bearing box bore with the bearing are specified according to GB1031 - 83. The Ra value of the shaft neck roughness is less than 1.6 mu m, and the bore roughness Ra of the bearing case is less than 2.5 mu m.3), bearing rings and roller manufacturing with GCr15 and ZGCr15 steel, the ring and the roller hardness value should be equal to 61~65HRC; GCr15SiMn and ZGCr15SiMn steel, the hardness of this value should be 60~64HRC. The hardness check method and the uniformity of hardness of the same part shall be stipulated by JB1255.4) check the bearings, radial clearance and axial clearance should be in line with GB4604 - 84 rules.5), rolling bearing the outer ring raceway should be no peeling, severe wear, both inside and outside the ring no after crack; ball should wear, the holder no serious deformation, rotation without abnormal noise and vibration should be gradually stopped, stop gap. 6, for the C tolerance class tapered roller bearing, the roller and raceway contact with a precision pump load with Germany for shrimp, color check into good, contact traces should be continuous, contact length should be less than no bus 80 roller.

- Q:Cooling method and structure of sliding bearing

- The so-called water cooling, that is, on the bearing body slot, can pass cooling water, the effect is better.

- Q:What are the requirements for the structure and properties of plain bearing materials and what are the materials used?

- Oh, just as I used to work as a technician in a miniature bearing factory for years. Rolling bearings rely on ball bearings to reduce resistance and support rotation; the sliding bearings depend on the clearance of the bearing bush to reduce resistance and support rotation. In sliding bearing, the Bush and lining are directly matched with the shaft neck, and there is friction between them, and they also bear the action of alternating load and impact load. The shaft is one of the important parts of the machine, the manufacturing process is complex, high cost, difficult to change, to ensure that the shaft is minimum wear, bearing hardness should be much lower than the shaft neck, if necessary, replace the bearing wear and continue to use the shaft. [properties]: sufficient compressive strength and fatigue resistance; good performance for reducing friction (friction coefficient is smaller); reserve good lubricating function; good adaptability; good thermal conductivity and corrosion resistance; good process performance, which is easy to manufacture, low price. A material can not meet the performance requirements at the same time. The sliding bearing alloy can be inserted into the bush of the 08 steel by casting method, and the bimetallic bearing can be made.

- Q:What are the main structures of radial sliding bearings?

- Self aligning bearings can automatically adjust the axis to accommodate the deflection of the shaft.

- Q:What are the main structures of radial plain bearings? What are their respective features?

- Self - aligning bearings can automatically adjust the axis to accommodate the deflection of the shaft

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Bearing Bearings 7017 Angular contact ball bearings 7017 Angular contact ball bearing

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 500000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords