Basalt Roving for Chop High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

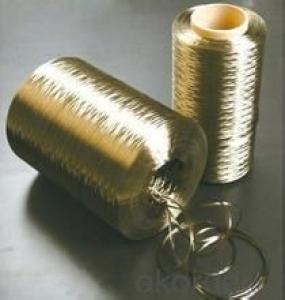

Description of Basalt Fiber Roving

Basalt fiber roving is a material made from extremely fine fibers of basalt, which is composed of the minerals plagioclase,

pyroxene, and olivine. It is similar to carbon fiber and fiberglass, having better physicomechanical properties than fiberglass, but being significantly cheaper than carbon fiber. It is used as a fireproof textile in the aerospace and automotive industries, and can also be used as a composite to produce products such as camera tripods.

Specifcation of Basalt fiber roving:

Filament diameter | Linear density | Sizing type | Agent content | Moisture content |

9 | 130 | Silane | ≤0.8 | <0.1 |

11 | 400 | Silane | ≤0.8 | <0.1 |

13 | 800 | Silane | ≤0.8 | <0.1 |

13 | 2400 | Silane | ≤0.8 | <0.1 |

13 | 1200 | Silane | ≤0.8 | <0.1 |

Field of application:

1. Winding tube, tank, cylinder

2. Weaving plaids, mesh cloth, geotextile

3. Repair and reinforcement for Building structure

4. as substrate materials of hihg temperature resistant chopped fiber thermoplastic composite of sheet molding compound (SMC, BMC), bulk molding compound (DMC)

5. Suitable for high-strength, high temperature winding, woven roving, pultrusion, injection molding, is as substrates to produce a variety of composite materials, but also as reinforcing material for the production of high-strength, SMC resistance

Packaging & Delivery

| Packaging Detail: | standard export package or as customer's requirements for 2400tex basalt roving |

| Delivery Detail: | Three to Five weeks |

- Q:What are used to produce glass?fiber geogrids.

- It is mesh structure materials made by certain weave technology in order to improve the overall usability. Glass?fiber geogrids with glass fiber twistless roving as the main raw material is also called fiber geogrid. Geogrid is excellent geotechnical base material formed by a special coating treatment process for the protection of glass fiber.

- Q:How to maintain the GRC exterior wall decoration components?

- According to DST, The texture of GRC wall decoration component must be alkali resistant glass fiber for reinforcement with right angle.

- Q:What can glass fiber grid do in road engineering?

- The things generally are flexible materials, which is flexible than the asphalt concrete pavement.

- Q:What kind of knife can used to cut glass wool cloth?

- You just need to cut off the big square. At first, you need to cut off the big square along border line and center line. Then you should cut off the two overlapping rectangles along the diagonal. At this moment, there are four right triangle which just can be put into a hollow square with its area just is equal to the small square, then you should put the small square into the hollow aquare.

- Q:Carbon fiber is better than glass fiber reinforced plastic

- Carbon fiber has many excellent properties, carbon fiber axial strength and high modulus, low density, high performance, no creep, non oxidation under the environment of high temperature resistance, good fatigue resistance, between heat and electrical conductivity between the metal and non metal, smaller thermal expansion coefficient and anisotropy, good corrosion resistance, X Radiability good. Good conductivity, thermal conductivity, good electromagnetic shielding, etc..

- Q:Knowledges of bamboo fiber.

- The production process of bamboo fiber: bamboo, bamboo pulp, crude fiber - fiber carding - spinning - textile. Characteristics of bamboo fiber fabric is: antibacterial, high strength, healthy, moisture absorpotion, cooling, deodorization, kept warm, soft and comfortable. Especially suitable for infant clothing. It is a good choice.

- Q:What can glass fiber do?

- Building for external wall insulation layer, glass fiber clothes are used in the glass fiber industry. The main effect is to increase the strength.

- Q:What is sheaf packing in waste plastic industry?

- 1, It is sheaf packing, but not the debris or particles packed space bags. 2, White cast is the color of fracture part and it includes blue, white and slant blue. The white cast should be transparent or white.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Basalt Roving for Chop High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords