Basalt Fiber Fabric With different Mesh Size

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m³

- Supply Capability:

- 1000000 m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Basalt Fiber Fabric Introduction

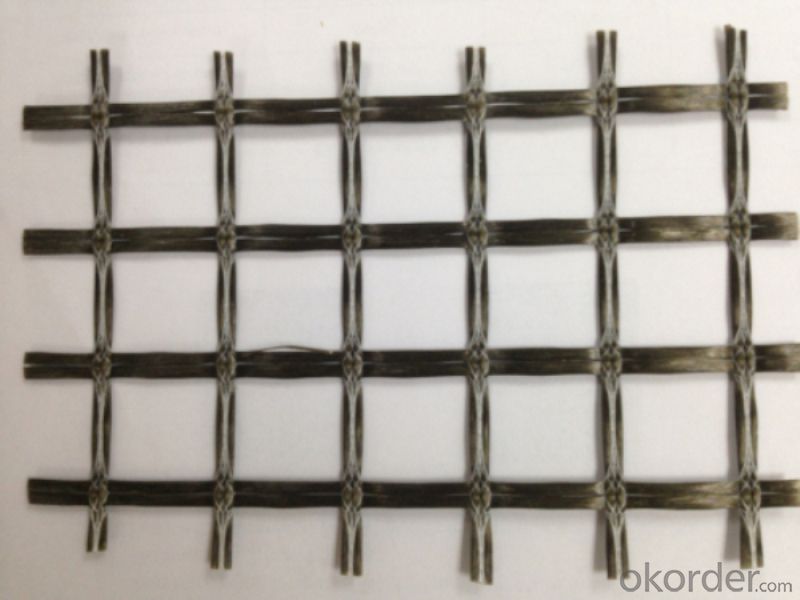

Continuous basalt fiber fabric is made by impregnating woven basalt fiber scrim with asphalt and then drying to be made.

In the normal temperature, the ratio of the elastic modulus between the basalt fiber concrete and the asphalt concrete is 24: 1.

Advantages of Basalt Fiber Fabric

Basalt fibre concrete has the excellent resistance to deformation, the elongation at break is about 3.1%. Basalt Fiber owns the high-temperature resistance, frost resisting resistance (-260~650 ℃), the same thermal expansion coefficient with the asphalt concrete, the high tensile strength, ultraviolet resistance, the stable chemical resistance, ageing resistance. The stirring temperature of the asphalt concrete is up to 190℃. The high-temperature Basalt fiber is the best alternative of the polyester fiber. It can satisfy the asphalt stirring temperature (190 ℃), and it is the excellent construction material for reinforced cement & concrete, and it has the outstanding penetration resistance.

Basalt fabric/geogrid/geotextile is more durable than metallic and glass-fiber reinforcement due to basalt fiber’s excellent performance.

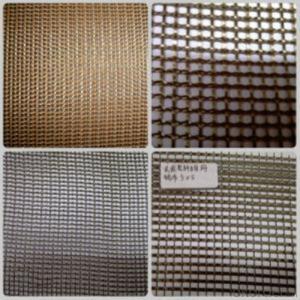

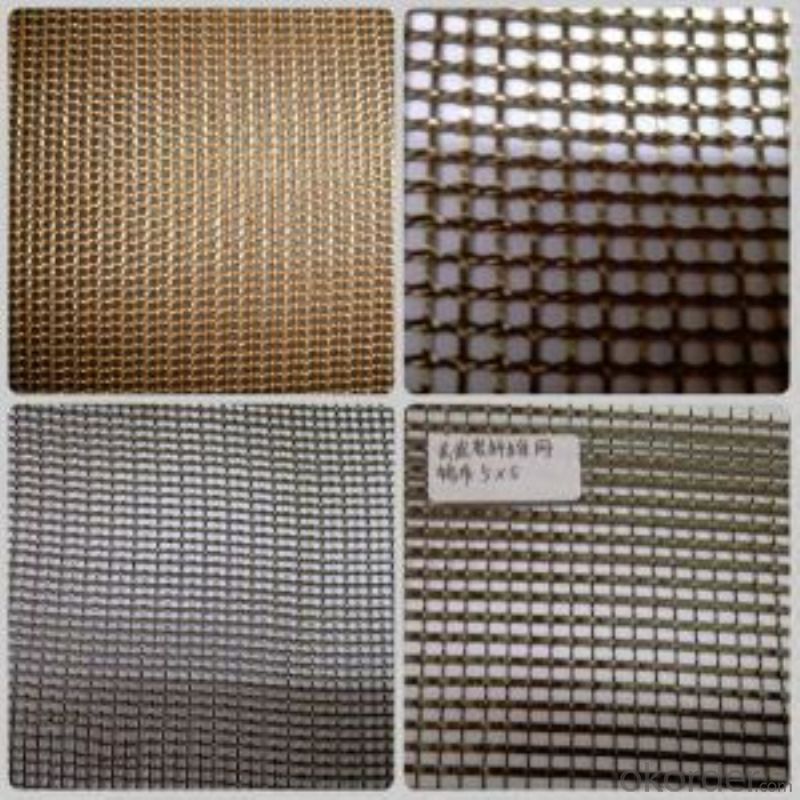

Specifications of Basalt Fiber Fabric

Item No. | Weight (g/m2) | Size (mm) | Thickness (mm) | Width (mm) | Roll Length (m) |

CMAX-250 | 250 | 5X5 | 0.6-0.7 | 300-2000 | 50m~100m |

CMAX-120 | 165 | 10X10 | 0.7-0.8 | 300-2000 | 50m~100m |

CMAX-300 | 350 | 25X25 | 0.8-0.9 | 300-2000 | 50m~100m |

Application of Basalt Fiber Fabric:

-laying of cement concrete pavement

-the reinforcement of the piers, dams,road and buildings

-building surface drywall joints

-cement mortar or concrete pouring

FAQ:

1. Which payment do you accept?

For you convinience, our payment can be L/C,TT

2. Is free sample available?

We can supply free samples. You'll just need to pay for express cost.

3. How about your quality?

We have strict quality control system, we make testing on incoming raw material and finished products. Your third party testing is also welcomed. With high quality, our products are used on government projects at home and abroad. Our product quality is accepted by clients from all over the world.

4. When will you reply my request?

You are our expected customer, we’ll reply your request within 24hours. Please feel free to contact us at any time.

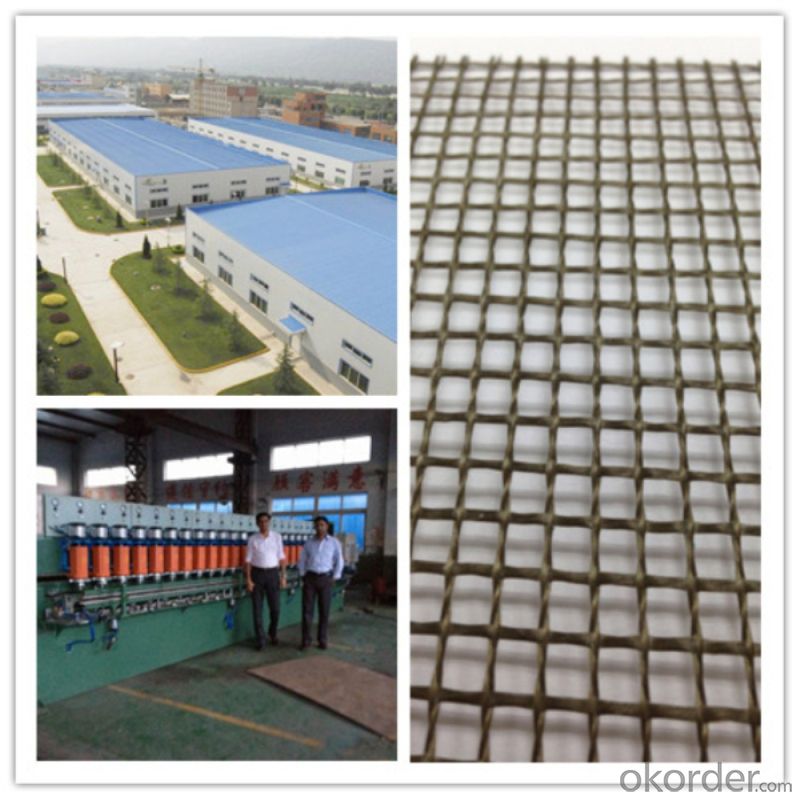

Photo of Basalt Fiber Fabric:

- Q:Who can tell me how much temperature of carbon fiber, glass fiber, basalt fiber and its composite material?

- As far as I know, glass fiber and basalt fiber products temperature resistance from 100-1600 (basaltic can be higher) The temperature of the composite material is usually specified at the specified temperature, the test base strength, deformation, as if there is no resistance to temperature this argument

- Q:What is the relationship between igneous rocks and basalt and granite

- Basalt A kind of dense or foamy rock that is solidified from a volcanic eruption, which belongs to a magmatic rock. The basalts are generally black, sometimes grayish green and dark purple, etc. The granules are fine and have a patchy structure in which the pores Construction and almond construction are common.

- Q:Basalt and limestone Which rocks are not suitable for building materials? why

- Basalt and limestone can be used as building materials. Basalt: the production of "cast stone" good material, need to be through the crystallization, bath fire treatment. It has done a casting machine and other machines, in the use of architecture is very large. Limestone: referred to as "limestone", for the casting of walls and other buildings, the same use of great. If you want to build a stone bridge, it is recommended to use "basalt", if the construction is a large object such as walls, it is recommended to use "limestone".

- Q:Earth basalt volcanic eruption stone has a shell

- According to the content of SiO2 in the chemical composition, the content of SiO2 in the chemical composition (SiO2 is more than 65%), the neutral rock (SiO2 is between 52% and 65%), the basic rock (SiO2 is between 45% and 52% , Ultrabasic rocks (SiO2 less than 45%). Basalt is just one of the basic rocks. Its chemical composition is silica, aluminum oxide, iron oxide, calcium oxide, magnesium oxide (and a small amount of potassium oxide, sodium oxide), the mineral composition is mainly composed of basic feldspar and pyroxene, secondary minerals are olives Stone, hornblende and biotite, etc., the rocks are dark, usually black, sometimes gray and dark purple and so on.

- Q:Basalt stone is corroded steel

- Which is more stomatal basalt, also known as pumice, its stomatal and hard texture, it can be mixed with concrete, can make the weight of concrete to reduce, not only durable, while noise, heat insulation and other characteristics, is high-rise building Good aggregate for lightweight concrete. Pumice is still a good grinding material, can be used to mill metal, grinding stone; in the industry can do filters, dryers, catalysts, etc., but also widely used in landscape, mainly for rockery, bonsai, etc. , But also for home decoration.

- Q:What is tholetic basalt?

- The pull basalt (ie, sub-alkaline basalt) is rich in SiO2 (49-51%) or saturated with SiO2 (the relationship between SiO2 and the whole base is (Na2O + K2O) / (SiO2-39) is less than 0.37) Alkali, mineral composition for the long stone - feldspar, pyroxene composition of poor calcium. There is little or no olivine (seen in porphyry). Produced in the Pacific Ocean volcanic belt on the ocean side, the basic part of the oceanic crust.

- Q:Useful basalt chopped fiber

- There is, added in the concrete, play a strengthening, anti-cracking effect.

- Q:Basalt fiber posing carbon fiber how to distinguish?

- Such as you take basalt cloth and a SW-I-300 carbon fiber cloth, the sensitivity is different, the basalt appears dark subtle, carbon fiber cloth color bright, and then were on the hands of rubbing. You will find that the hand of carbon fiber cloth is clean, no trace, while the basalt cloth will finger black, and itchy.

- Q:Basalt and the difference between Andesite

- From his surface weathering color, fresh face color, composition, structure, silica content, etc.

- Q:Online and so on - detailed definition of stomatal basalts and almond basalts

- Basalt is the main component of sodium aluminosilicate or calcium aluminosilicate, the silica content is about 45-52%, also contains high iron oxide and magnesium oxide, is a fine dense black rock. Due to the eruption when a large number of pores, sometimes large holes such as almond-like structure, and later often filled with other minerals. This is the stomatal basalt and almond basalt.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Basalt Fiber Fabric With different Mesh Size

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m³

- Supply Capability:

- 1000000 m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords