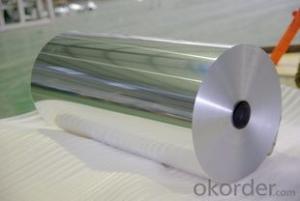

Barbecue aluminum foil

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Aluminium is a relatively soft,durable, lightweight, ductile and malleablemetalwith appearance ranging from silvery to dull gray, depending on the surfaceroughness. It is nonmagnetic and does not easily ignite. A fresh film ofaluminium serves as a good reflector (approximately 92%) of visible light and an excellent reflector (asmuch as 98%) of medium and far infrared radiation. The yield strengthof pure aluminium is 7–11 MPa, while aluminium alloys have yield strengths ranging from200 MPa to 600 MPa. Aluminium has about one-third the density and stiffness of steel.It is easily machined, cast, drawn and extruded.

Aluminium alloys (or aluminum alloys; see spellingdifferences) are alloysin which aluminium(Al) is the predominant metal. The typical alloying elements are copper, magnesium,manganese,silicon,tin and zinc. There are twoprincipal classifications, namely casting alloys and wrought alloys, both of which are furthersubdivided into the categories heat-treatableand non-heat-treatable. About 85% of aluminium is used for wrought products,for example rolled plate, foils and extrusions.Cast aluminium alloys yield cost-effective products due to the low meltingpoint, although they generally have lower tensile strengthsthan wrought alloys. The most important cast aluminium alloy system is Al–Si,where the high levels of silicon (4.0–13%) contribute to give good castingcharacteristics. Aluminium alloys are widely used in engineering structures andcomponents where light weight or corrosion resistance is required

Secification:

Alloy : AA1235/1050/1060/1100/3003/8011/8006/8079/8021etc.

Temper: H14/16/18/22/24/26, HOetc.

Thickness: 0.006mm—0.20mm

Width: 200mm—1600mm(Can be slitted)

Coating : HSL/Primer

Color : Accordingto customers’ requirements

Feature:

100% safe

Environmentally friendly, recoverable and recyclable

Used for storing, packing, grilling/ baking, heating andfreezing

Customized orders available

High-temperature sterilization

Aplication:

Food Packing, Household Application, Cigarette Packing,Lamination, Medicine , Printing, Heat Sealing, Beer Packing, RoofInsulation Materials, Honeycome Materials and so on.

Packaging Detail: Carton ,Wooden pallet with plastic protection packing,standard seaworthy packing or as your request.

ProductionCapacity:

AnnualProduction capacity of 600,000 tons.

Products areexported to United States, Canada, U.A.E, Brazil, Mexico,Thailand, Vietnam,Nigeria etc, over 100 countries andregions all over the world.

Coveredfactories with full production line

CNBM aluminumproduction base is comprised of 18 aluminumannealers, 10 coil and foilmills, 4 continuous production lines, 2hot rolling production line and 3prepainted lines.

FAQ:

1. What is the form of payment?

Normally 30% TT, L/C

2. Type of quotation?

FOB, CFR, CIF

3. Port of loading?

Shanghai port

4. Delivery time?

40 day after client’s deposit

- Q:I put a bag over it hoping it would stop the signal but it doesn't workHow do I block it, do I need something thicker?

- you need something radiopaque like aluminum foil, try that

- Q:I bought Bertolli stuffed shells and did not read the instructions while in the storeTurns out it says to bake the shells for 40 minutes wrapped in aluminum foilI don't have aluminum foilHow can I bake them without the foil?

- Because they don't deserve any presents.

- Q:I know this isnt the place to ask but I really need help and Im confused with the two.Im trying to find the hypothesis.1- Independent variable- amount of gas bubblesdependent variable- number of raisin round tripshypothesis- ?2- Independent variable- number of recycling postersdependent variable- amount of aluminum cans in courtyardhypothesis- ?Please helpIm just confused at the moment

- I don't get question 1 (number of raisin round trips?), but here's question 2: 2) Hypothesis: I think the more recycling posters there are, the more people will recycle aluminium cansBy the way, independent variable is the thing you change, dependent variable is what you measureThere is another variable, controlled variables which are things which stay the same throughout the whole experimentThe hypothesis is your guess at what the answer will beIt is not the aim, which is the question for the experimentExamples: hypothesis: I think the hotter it gets, the faster water will evaporate Aim: To find out if temperature affects the rate at which water evaporates Hope this helps!

- Q:I'm making teriyaki chicken wings for a large groupI currently have the wings marinating in the sauce mixture, but I want to baste them while they're cooking.Is it safe to baste them with the same sauce I marinated them in, or would that get people sick? Also, if you have any tips on how to properly baste the wings, I'd love to hear them! Thanks!

- I would first start learning by watching YouTube videos about knittingThat's one place you could start.

- Q:and there a really cute boy that i want to inpress

- Definitely sunscreen, a hat and insect repellentRed skin and itchy spots will be a big turn off for your boy! How about some games you can play with this boy, cards, board games, sports gamesSome good shoes so you can go hiking togetherHave fun!

- Q:Yes, there the ones from stor that are readyYou just have to put them on the oven.

- On the oven rack? NO way unless you want a burned mess on the bottom of your ovenYou need to use a cookie sheet, or at least some sort of flat surfaceFoil is not necessary.

- Q:or both, or neither?1free of chromatic aberration2has more severe spherical aberration3requires aluminum 4can be used for photography5Can be made in larger sizes6has a prime focus at which a person could work without blocking the incoming light7used to observe gamma rays

- 1) Reflectors are free of chromatic aberrationModern apochromatic refractors come really close though2) Neither, I thinkSpherical aberration depends on the exact mirror or lens shapes3) NeitherReflectors usually use aluminium-coated glass, but older ones used silver-coated glass and the first ones used polished metal4) Both5) ReflectorsThe aperture limit for a refractor is about a metre because the lens can only be supported round the edge6) All refractors and a few off axis reflectors, but not common Newtonian or Cassegrainian reflectors7) NeitherX-rays can be reflected, but gamma rays are too high energy.

- Q:aluminum, Z 13phosphorus, Z 15

- try making it outside the house.

- Q:How can aluminum foil and aluminum membrane be distinguished?

- Six, knife scraping: aluminum foil with a knife can scrape the aluminum chip, then the aluminized film will not scratch the aluminum chip, and will be transparent on the film.Seven, fire fire point: aluminum foil is not easy to burn, the aluminum layer will rollback, burn after leaving aluminum foil packaging slag grey. When aluminum film is burned, the combustion of different plastic film can occur, and there is no residue of aluminum residue.

- Q:Ok, I've changed this thing 3 times nowCompletely cleaned the old gasket, tried both with without permatex, properly torqued, after installation run a check with engine running at operating temp, no leaksAfter a week or so, it's leaking again like crazyONLY thing I can remember that's off is the fact that the original gasket was square so it fits flush against the block, all the newer gaskets are round, does this really make a difference? Somebody help plz, signed quot;bout to turn green and flip this dang truck overquot;

- Get a cut off of non-slip lino to fit under the cage (see if carpet shops have scraps) and then get a cheap rug or pet blankets to go on top of that she doesn't slip aroundDone!

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Barbecue aluminum foil

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords