BALL VALVE of Forging Steel Full-welded API6D/CE/ISO9001 CERTIFIED

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

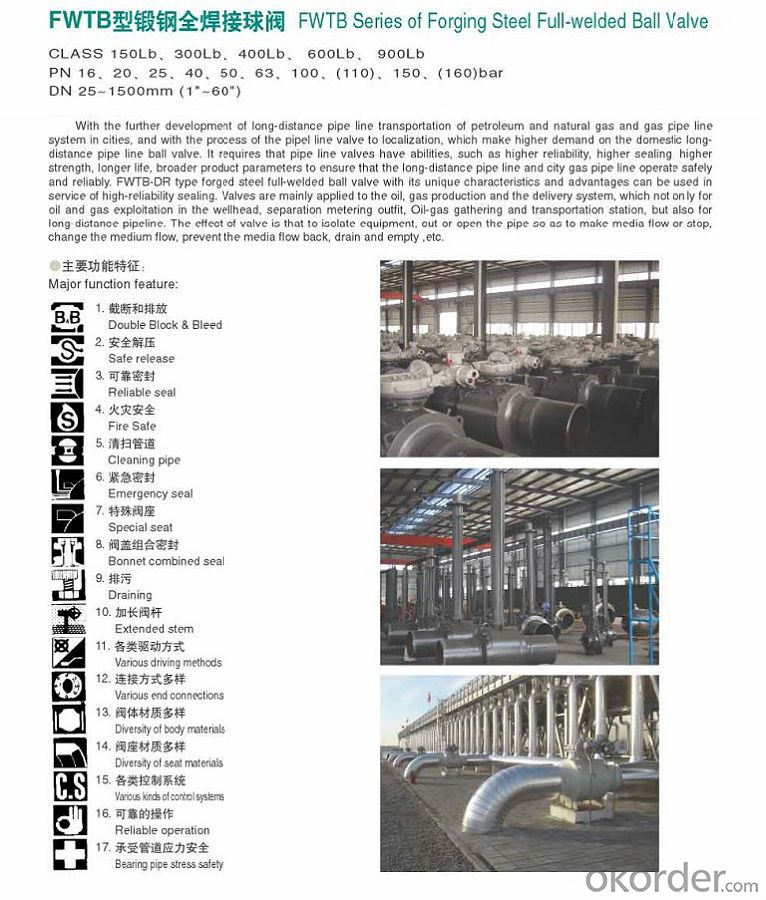

FWTB Series of Forging Steel Full-welded Ball Valve

With the furture development of long-distance pipe line transportation of petroleum an nature gas an gas pipe line system in cities,an with the process of the pipe line valve to localization,which maker higher demand on the dnomestic long-distance pipe line ball valve.FWTB-DR type forged steel full-welded ball valve with itsunique characteristics an advantages can bu used in service of high-reliability sealing.Valves are mainly applied to the oil,gas production and the delivery sytem,which not only for oil and gas exploitation in the wellhead,separation metering outfit,oil-gas gathering and transportation station ,but also for long-distance pipe line.

Design codes anregulations

API:6D/Q1/607/6FA/598/5L

ANSI/ASME

ASME section V/VIII/IX

B16.5/B16.10/B16.25/B16.34/B16.47/B31.8

MSS-SP:SP-6/SP-25/SP-44/SP-45

NACE:MR0175/TM0177

BS 5351

ISO5211

Materrial regulations:

ASTM:A193/A193M/A194/A194M/A313/A313M/A105/A350/A350M/A694/A694M

Strukture characteristics

Selection of material

The selection of valve part material conforms to the requirements in regulations of API 6D,ASTM,ASME and etc.

Double Block & Bleed(DBB)

Forging steel structure

Low torque in operation

Reliable sealing

Emergency sealing

Enptying device

Fire Safe

Anti-statc design

Extension stem

Various driving types

The top pad of valve designed according to ISO 5211.

- Q:Here, the original water leakage, has not been closed, recently closed for other places, twisted two times, and now it is so,Ball valve leakage of this place, how do? Here, the original water leakage, has not been closed, recently closed for other places, twisted two times, and now it is the case, how can I ask?

- 1, if it is household valveA, the valve and pipe connections at the leakage, in the connection, do not rub tape (the best counter clockwise direction, so that when the valve is connected, the more twisted the more tight) ;B, if the valve itself in the leak, there are ways, it is necessary to open the valve, in which to add sealed or O ring, but it is recommended to replace a more convenient.2, if it is industrial valvesA, industrial valves leaking, if not the valve itself in the leak, then in the valve and pipe connections to join the sealing ring,B, if the valve itself is leaking, it is best to return to the manufacturer for maintenance, if not convenient, then only the manufacturers to come here for maintenance.

- Q:What does the RTFE say in the ball valve?

- RTFE reinforced PTFE is more wearable than PTFETeflon PTFEThe seat of tetrafluoroethylene specified for a temperature range of ~200 DEG C -32. High temperature resistance and chemical resistance. Because of its high density and good permeability, PTFE can also prevent the corrosion of most chemical media.Conductive PTFE is an improved PTFE product that allows the current to pass through the lining and thereby cancel the insulation properties of ptfe. Because of its conductivity, conductive PTFE can not be checked by edm.+ reinforced PTFE RTFERTFE is a modification of PTFE material. Pure PTFE although very low coefficient of friction (0.02~0.04) but the wear volume is great, but also because of its easy creep, poor mechanical properties, low bearing capacity, poor dimensional stability characteristics such as friction material has great localization. Only modified by compound method to meet the special requirements of all walks of life sealing material on the wear resistance, to improve the wear resistance of PTFE, can be incorporated into some wear-resistant materials such as glass fiber, carbon fiber, graphite, molybdenum disulfide, bronze powder and some organic compounds, making them reticular junction formed in the PTFE layered structure so as to improve the the stiffness, thermal conductivity, creep resistance, and greatly improve the wear resistance.PTFE is composed of tetrafluoroethylene monomer polymerization of the polymer, the wax is similar to a PE transparent or opaque, its density is 2.2g/cm3, the water absorption rate of less than 0.01%. Its chemical structure is similar to that of PE, except that all hydrogen atoms in polyethylene are replaced by fluorine atoms. Because the C-F bond is high and stable in performance, it has excellent chemical resistance

- Q:What do you mean by 266 in the 266 brass ball valve?

- This is the Ningbo aimeike Copper Valve Co Ltd model, 266 is only a brass ball valve series, specifically to check samples.

- Q:Ball valve specifications are represented by 2 FF,

- FF refers to the form of connection between the valve and the pipe lineFF, or Flat Face, is a common form of flat flange connection

- Q:Pneumatic two stage ball valve principle

- Pneumatic refers to the valve is automatic operation, power is compressed air;Two paragraph refers to the structure of the valve, that is, the body is composed of two parts connected by flanges, of course, there are other forms of a chip, three pieceTwo and two pieces mean one thing

- Q:The working principle of the track type ball valve

- No wear and tear of switch:The ball core deviates from the valve seat and then rotates, eliminates the friction of the valve seat, and solves the abrasion problem of the seat of the traditional ball valve, gate valve and plug valve.Anti friction valve hard and dense cover:The surface of the ball core is welded with a hard polished sealing surface, which can ensure the sealing performance under very severe working conditions.

- Q:What's a twin hot melt ball valve?

- Is a plastic ball valve, connecting France is hot melt.

- Q:Hard sealing ball valve, what method can calculate the leakage? How much is grade 4? How much is grade 5? How much is level 6? For example: how many DN150 seals are 5 ml?

- Valve leakage level is used as an important reference standard in valve leakage test.Usually in accordance with the requirements of the process. In the process of lifting the conditions and processes, there will be valve leakage level requirements.

- Q:What does one inch of an ice ball refer to?

- An inch refers to the valve's medium channel is%%C25mm

- Q:What is the difference between PPR ball valve and PPR live ball valve?

- PPR and PPR union ball valve is different: PPR union ball valves and pipes on both sides (hot melt) connected between, a movable joint (hot melt) and (link with) nut, maintenance, convenient disassembly and replacement of the valve, the union not only cut off the PPR ball, maintenance.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

BALL VALVE of Forging Steel Full-welded API6D/CE/ISO9001 CERTIFIED

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords