Automatic Wrap around Packers

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

1.Composed of:

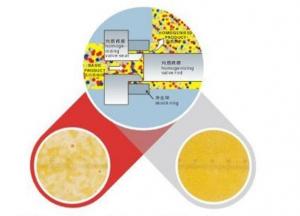

1.1 Infeed conveyor 1.2 Cardboard feeding 1.3 Bottle separating 1.4 Main frame 1.5 Cardboard feeding 1.6 Bottle pushing 1.7 Carton folding conveyor 1.8 Up and down clamping

2.Working principle: Containers are conveyed to the bottle separation section, the bottle separating system separate bottles into scheduled packing collocation, cardboards are distributed to the climbing section then to synchronous conveying section, cardboard and products are conveyed to glue spraying section, when products pass through they will be wrapped and glued, after that the carton is clamped tightly, which makes the carton glued.

3.Performance parameter:

3.1 Capacity: 45PPM 3.2 Packing type: wrap around 3.3 Applicable bottle:

(1) Glass, PET bottle and can etc. diameter ranges: Ø50~110mm

(2) Bottle height: H70~360mm 3.4 Carton size (1) L200~530mm (2) W200~350mm (3) H70~360mm 3.5 Cardboard specification:(1)Material:corrugated paper (2)Thickness:3mm (3)External covering pressure:150~200 g/m2

(4)Internal covering pressure:150~200 g/m2

(5)Central covering pressure:150~180 g/m2 3.6 Bottle separating type: servo motor

4.Other parameter:

4.1 Machine size: a.Infeed conveyor: L3430mm,mat top chain width: 508mm ` b.Cardboard magazine: L2710mm,mat top chain width: 996mm

4.2 Total power:23.1 Kw

4.3 Control power:24V DC

4.4 Compressed air (a) Pressure:0.6MPa (b)Air consumption:100L/Min

- Q:The working principle of gas filling machine

- Pressure filling machine is higher than normal pressure conditions for filling, can also be divided into two kinds: one is the pressure inside the tank and the bottle in the same pressure, by the liquid weight into the bottle and filling

- Q:What do the filling crew do?

- 3, monitoring the filling machine of the data, the temperature ah, the pressure ah, there is a simple problem solving, complex issues notify the machine repair.

- Q:What is the flexible container seal?

- ② plastic film bags and composite film bag sealing device: with a good thermoplastic plastic bags or composite bags, generally used in the sealing at the direct heating and mechanical pressure, so that sealing fusion.

- Q:On the sparse under the dense gradient density filter bed structure features:

- 5, low dosage, low operating costs: the filter bed structure and the characteristics of the filter itself, flocculant dosage is conventional technology 1/2 to 1/3.

- Q:What is the water purifier?

- Ultrafiltration machine is the main water purification equipment in the water treatment equipment, with high precision, good cleaning effect, filter long life, and can automatically clean the filter.

- Q:For the quality of the beverage produced by the filling machine

- May be like "the weight of each bottle is not the same, and some irrigation more, some irrigation less" or "filling speed is too slow, 1 minute to fill a bottle."

- Q:The filter material is preconcentrated

- Increase, in a very short period of time was forced to stop the filter, the media rinse regeneration.

- Q:Water treatment household equipment

- In the water home improvement, the main is soft water and pure water equipment.

- Q:Easy to control, easy to achieve automated production

- 6, the equipment is simple, advanced technology

- Q:Vertical continuous pressure leaf filter

- Complex structure, suitable for large-scale production and automated control operations.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Automatic Wrap around Packers

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords