Automatic Valve Paper Bags Making Machine Price

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 0.2 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

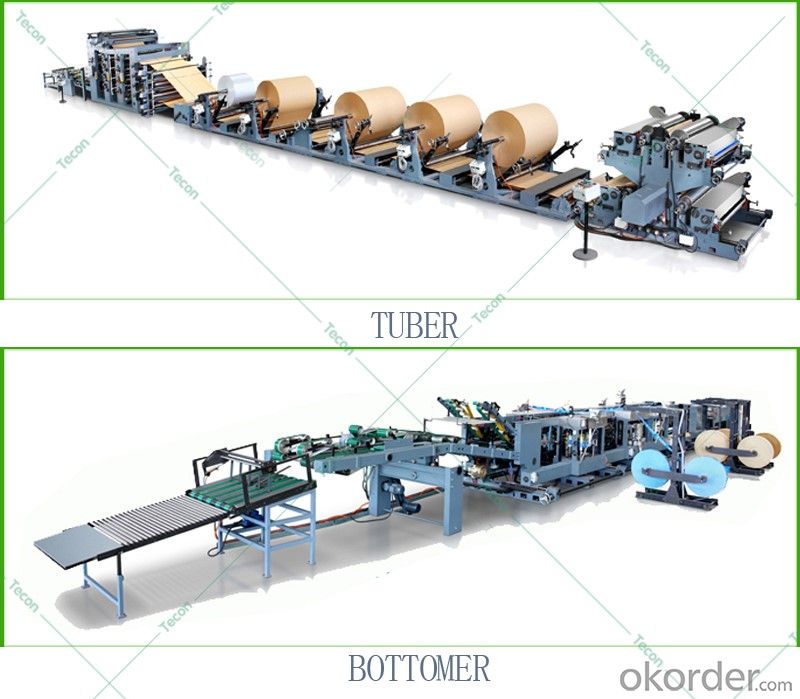

Our paper bag production line consists of paper tube forming machine(Tuber) and bottom pasting machine(Bottomer). The products-Valve bags are used for a vast number of applications, primarily in the building materials and food industries, to filling goods such as:cement,chemical material, feeds, fertilizers,tea,rice etc.

Our Advantage:

1.Specialize in design and manufacture valve paper bag machine for 30 years;

2.CE Certified;

3.Our tuber machine and bottomer machine have gained over 50 utility model patents;

4.Longer service life with NSK bearings,SIEMENS control system and high quality gearings.

5.Cost effective compare to W&H,Germany and Newlong,Japan.

Valve paper Bags:

Different models can produce different kinds of bags,like standard cement bags,chemical/cement bags with bottom strengthen sheet,tea bag with PP Liner to enhanced moisture protection.

Bags can be made of 2~4 layers kraft paper or paper with one layer of PE/PP film.2~4 colors printing available in Tuber line.

The bags opening or valve in one corner through which the sack is filled. The valve is made with an inner flap which functions as a self-closing check valve after filling. It is available with a plain valve or with an extended inner sleeve of paper or film.

Machine Technical Parameters:

| Model | ZT9802S |

| speed | 120 tubes/min |

| Tube Width | 380~620mm |

| Tube length | 400-1400mm |

| Specification gear | 51~80 teeth(M=4) |

| Type of cutting | Step cut&Flat cut |

| Number of ply | 2~4paper+ 1 PP/PE |

| Diameter of print roller | Ø196~ø312 mm |

| Printing width | 1300 mm(MAX) |

| Paper reel diameter | Max. 1, 300 mm |

| Paper reel width | 860--1260mm |

| Main drive motor | 47KW |

| Servo system | YES |

| Machine size | 35.32.42.7(M) |

| Machine weight | N 32(T) |

HD4916BD Bottomer Machine

| Model | HD4916BD |

| Speed | MAX 100/140 bags/minute |

| Tube Width | 380~600 mm |

| Bottom Width | 80~160 mm |

| Valve Sheet Length Width | (100-300)(120-240)adjustable |

| Bag Length | 520~880 mm |

| Bottom Center Distance | 420~780 mm |

| Number of ply | 2~4paper+1 PP/PE |

| Strength sheet unit | YES |

| Strength sheet length*width | (300~600)(80~160) |

| Main Drive Motor | 40KW |

| Machine size | 23/281.81.8(M) |

| Machine weight | N34(T) |

Product show:

After-sale service

1.Provide training during and after the commissioning at the buyer site.

2.One year warranty period from the acceptance at the buyer site.

3.Provide life long technical services and effective solutions.

- Q:How are plastic products formed?

- 1, calendering calendering for thermoplastics. It is through Plasticating plastic, sent to several groups of parallel arrangement, reverse rotation of the heat roller, by repeatedly calendering products. Production of film or sheet.2, casting casting with dry plastic. It is soluble in the solvent of plastic, due to weight andspread to continuous operation of the metal belt, become thin layer of uniform thickness, then heating apparatus soft volatile agent, curing products, production of film or sheet.3 、 extrusion molding, extrusion molding, used in thermoplastics. This is a melt plasticized plastic which is extruded from the die cavity of the die at the head of the extruder and forms a profile similar to that of the die. It produces plates, pipes, bars, wires, profiles and so on

- Q:How to solve the main motor failure of aluminum-plastic packaging machine?

- Treatment method:(1) check the power line, the motor lead line, fuse, switch each pair of contacts, find the open circuit position, to be ruled out;(2) after unloading or half no-load start;(3) check the dragging machine to remove the trouble;(4) check the joint of the contacts of brush, slip ring and starting resistance;(5) re judge the end and end of the three-phase, and check whether the three-phase winding has the line and the short circuit.Motor starting difficult, plus rated load, the speed is low.

- Q:What are the sensory standards in the hygienic standard for polyethylene used in food packaging?

- Poly (ethylene terephthalate) for food packagingPETBottle blankOneRangeThis standard specifies polyethylene terephthalatePETRequirements, testing methods, inspection rules, labelling, marking, packaging and transportation of containersAnd storage.This standard applies to bottle used polyethylene glycol terephthalate

- Q:Why should heat treatment be made after glass molding?

- But not so cool to room temperature, due to stress induced crack

- Q:How does the lost foam forming machine work?

- Lost foam molding machine has two kinds of automatic and manual, manual operation is controlled by hydraulic valve, so that the molding machine on the template, left and right templates, front and rear templates in accordance with the design of the mold in order to open and close. The aged expandable polystyrene beads are filled into the closed cavity, and the hot steam passes through the air holes of the wall directly into the cavity in a relatively short time, so that the beads expand and soften after being heated. Because of the limitation of the cavity, the expanded bead fills up all the voids and is completely bonded to a whole. After cooling and shaping, the mold is opened and the mold is taken out.The automatic EPC machine adopts the PLC automatic control hydraulic valve according to the order of the manual to complete the opening and closing of the die.

- Q:Characteristics of various biscuit forming methods

- Chinese Name: BiscuitForeign name: BiscuitMain ingredients: wheat flour (added glutinous rice flour, starch, etc.)Palate: crisp or crunchyHow to eat: it tastes great with milk

- Q:Foam box production equipment, where is the production of seafood boxes, such as foam box machine?

- VFS5000FS what's the name of the conveyor belt under the shaper of the automatic packing machine?

- Q:What are the characteristics of plastic thermoforming?

- Thin to0.1mmMost of the hot forming products are concave, convex, semi shell, and their depth is limited. Most of the hot forming parts are thin wall, and the thickness of the original sheet is0.2mmThe thickness of the actual product is smaller, and the thickness of the special thin product is up to0.05mm.2.A wide range of applications. Due to the thermal molding adaptability, its scope of application. From the tablet packing to the refrigerator liner, even to the aircraft hatch cover, can be obtained by thermal moulding method. A cup dish and other household utensils, utensils, medical electronic instrument accessories, radio and TV, billboards, bathtub enclosure and toys and other products. - packaging type. Another car components of building components, chemical equipment, radar cover and aircraft cabin cover tray.3.Equipment investment is low. Because of the simple molding equipment and the low total pressure required, the requirement of pressure equipment is not high, so the thermoforming equipment has the characteristics of low investment and low cost..4.

- Q:Carton packaging in the form of technology, including several major categories

- Carton is a three-dimensional shape, it is composed of a number of components of the surface movement, accumulation, folding, surrounded by a multi-faceted form of body. The plane in the three-dimensional structure plays the role of dividing space in the space, cutting, rotating and folding the different parts of the face, and the resulting surface has different emotional expression. The relation of the display surface of the carton shows the connection of the surface, side, top and bottom,

- Q:Plastic packing bag sealing, 3 sides forming, sealing and 4 sides sealing what does that mean?

- You should ask three sides and four sides. See the picture below.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Automatic Valve Paper Bags Making Machine Price

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 0.2 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products