Automatic Extrusion Blowing Machine for LED Light PC Cap

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 4 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Automatic Extrusion Blowing Machine for LED Light PC Cap

LED Light PC Cap Automatic Extrusion Blowing Machine Production Line Feature:

Reasonable equipment design, compact construction, simple operation

Equipment with high degree automatic, cost less expenses

Electrical equipment, Hydraulic system, Seal parts and Lubrication system adopt the components of famous factory in the world, with low failure rate.

To achieve the best quality guarantee, no matter the appearance and internal, automatic extrusion blowing machine rate of quality goods is above 99%.

LED Light PC Cap Automatic Extrusion Blowing Machine Technical Characteristic:

LED Light PC Cap Automatic Extrusion Blowing Machine adopt European technology, control the hydraulic system with pressure and flow double proportion. The speed of pressure can adjust nonpolarly, high stability, exchange control the electrical system with man-machine interface. Operating surface has a machinery safety configuration, two electrical safety configuration to ensure the safety of operators.

PLC+touch screen, making the operation easy. Automatic malfunction alarm with selfdiagnosis, making the malfunction clear at a glance.

Center input die head, eliminating the knit line completely and making it easy to change the material and color.

Double linear rolling motion guider in moving, opening and closing mold, making the clamping force equally distributed, so the cut is smoother.

Control the hydraulic system with imported proportional valve, ensuring the action steady, accurate and energy saving.

High speed and efficient plasticizing system, mixing well and ensuring the produce purity.

LED Light PC Cap Automatic Extrusion Blowing Machine Parameter:

Specifications | Unit | Parameters |

Max container capacity | L | 20 |

Extruder System |

|

|

Screw Diameter | mm | 82 |

Screw L/D ratio | L/D | 30:1 |

Screw Speed | rev. / min. | 10~50 |

Plasticizing Capacity | Seconds/die. | 60 |

Number of heating zone barrel | zone | 5 |

Extruder driving Power of barrel | KW | 34 |

Max Injection quantity | L | 1.5 |

Die Head |

|

|

Max die diameter | mm | 130 |

Number of heating zone | zone | 4 |

Extruder driving power | KW | 8.7 |

Clamping Device |

|

|

Platen Size(WxH) | mm | 440 x 600 |

Platen opening stroke | mm | 330~780 |

Clamping force | KN | 210 |

Next blowing Device |

|

|

Blowing the head off and landing trip | mm | 120 |

Manual control Blowing the head off and landing trip | mm | 80 |

Manipulator |

|

|

Take pieces of travel | mm | 1000 |

Framework |

|

|

Lift travel | mm | 250 |

Hydraulic System |

|

|

Rated pressure of big pump | Mpa | 14 |

Rated flow of big pump | L/min | 180 |

Motor power of Hydraulic pumps | KW | 45 |

Parison Controlling Of Hydraulic Servo System |

|

|

Rated pressure | Mpa | 6 |

Rated Flow | L/min | 22 |

Motor power of Hydraulic pumps | KW | 4 |

Pneumatical System |

|

|

Air source pressure | Mpa | 1 |

Working pressure | Mpa | 0.8 |

Air consumption | M3 / min. | 0.6 |

Electrical Control System |

|

|

Water Supply |

|

|

Water supply pressure | Mpa | 0.3 |

Power Supply | ||

Voltage | V | AC380V±10% |

Frequency | HZ | 50 |

Wire |

| 3Phase |

Total of rated power | KW | 91.7 |

Average power consumption | KW.h | 45 |

Total weight | Ton | 11 |

Dimension of machine (Lx W x H) | m | 5.3×2.7×4.5 |

LED Light PC Cap Automatic Extrusion Blowing Machine Parts Picture:

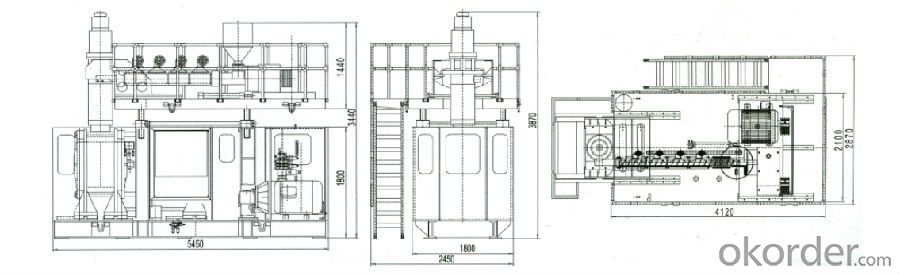

LED Light PC Cap Automatic Extrusion Blowing Machine Drawing Picture:

LED Light PC Cap Automatic Extrusion Blowing Machine Electrical Parts Photo:

LED Light PC Cap Automatic Extrusion Blowing Machine Products Photo:

- Q:What's the difference between a purifier and an oil purifier? Or the purifier is the oil filter

- The oil purifier basically eliminates impurities, and the purifier can also remove water except for impurities, but the average person thinks it is the same

- Q:What's the difference between a heated plate and frame oil filter and an ordinary plate and frame oil filter?

- Ordinary plate oil filter is composed of filter bed, pump motor and coarse filter element, filter bed is composed of multi level filter plate and the filter frame, filter paper or cloth lining the filter plate and the filter frame, with pressure filter pressing device, the filter chamber is fixed independently formed between the plate and the filter frame is pressed in between the filter plate and the filter frame of the paper or cloth to play the role of filtering. The heating plate oil filter is independent heating device based on general frame increase oil filter, to filter high viscosity oil, oil filter plate ordinary machine is not filtered for high viscosity oil.

- Q:Which is more practical, plate pressure type oil filter and multi-function oil purifier? What are their advantages and disadvantages?

- For example: DYJ series multifunctional lubricating oil purifier Chongqing Wanmei according to the characteristics of various types of oil kinematic viscosity, flash point index difference, a common type of specialized development and production of multifunctional lubricating oil purifier, suitable for lubricating oil of various types, different grades of effective purification. Is the industrial and mining enterprises to purify all kinds of lubricating oil ideal equipment. The two-stage or multi-stage vacuum purifier is more efficient.Use:Widely used in hydraulic oil, hydraulic transmission oil, gear oil, gasoline engine oil, diesel engine oil, compressor oil, refrigerator oil, heat treatment oil and so on. The utility model can rapidly remove moisture, gas and mechanical impurities in oil, flash out the light acid and light hydrocarbon, improve the quality of the oil, and restore the use performance of the lubricating oil. Ensure the normal operation of power system, hydraulic system and lubrication system.

- Q:What's wrong with the vacuum oil filter?

- The oil content is very high, and the vacuum oil filter with high viscosity oil is not considered. The wrong equipment is chosen, and the filtration efficiency is too slow. In general, the vacuum filter oil filter viscosity is too high, the oil must be double pump, otherwise, pumping force is not enough. If it is a high viscosity oil, such as filter gear oil, etc, the ordinary vacuum oil filter is adopted, the fluidity is poor and the filter oil is certainly slow.

- Q:Comment: what's the difference between a vacuum oil filter and a centrifugal oil filter?

- 3, focus on different application fields: vacuum filter oil machine with high precision, can filter the water and impurities, but also can remove gas, acid value reduction, therefore in the filtration of various industrial oil (lubricating oil, hydraulic oil, turbine oil, turbine oil, anti oil, transformer oil) and other areas of application is very wide. Centrifugal oil filter can filter water and filter impurities, but the speed and physical ability by centrifuge limit, filtering precision and filtering ability cannot and vacuum oil filter, therefore centrifugal mainly applied in food more oil fields, oil industry only in the filtering requirements without high requirement will be used centrifugal oil filter.

- Q:Under what conditions does the air pressure oil filter fail to clean oil?

- Oil is too dirty or used in an unsuitable oil filter. There will be filters that are not clean

- Q:How to choose the proper plate and frame pressure filter

- The filter function of plate and frame oil filter is realized by filter paper, and the filter paper intercepts impurity particles, so as to realize the function of filtering waste oil impurity. Generally filter boards and filter paper are easy to damage, filter paper is the biggest material, but the price is cheap, recommended model AXDLY.

- Q:Double barrel automatic electric heating centrifugal oil filter and oil separation automatic horizontal centrifugal oil filter which is better than

- Heating centrifugal oil filter is generally filtered, emulsified, that is, more water. Oil centrifugal oil filter oil filter more impurities

- Q:Is there a national standard for oil filters?

- The machine is composed of filter bed, oil pump and rough filter. With industrial filter paper as filter medium, different filter paper can be selected according to different filter requirements, and the filtering accuracy is high. The utility model has the advantages of simple structure, easy operation, low operation cost, etc..

- Q:How often do you change the oil filter when the turbine is in oil?

- When the new oil content is high, the filter paper will be changed in 1 hours. Are you using a plate type oil filter? We use, steam turbine lubricating oil system filter within 24 hours will alarm, indicating that the filter will filter scraps of paper jam, the actual collapse filters also illustrate this point, now the oil filter machine in our system has no.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Automatic Extrusion Blowing Machine for LED Light PC Cap

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 4 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords