Automatic Concrete Column Forming Machine

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 5 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Automatic Concrete Column Forming Machine

1. Structure of Automatic Concrete Column Forming Machine:

Automatic Concrete Column Forming Machine is our special developed products as results of our engineers research, with which 60%steel material will be saved compared with traditional revolving die method .Efficiency can be improved 3 to 5 times compared with conical die method, these machine are easy for operation and convenient for maintenance, products from these machines are in good quality, smooth appearance and accurate in size.

2. Main Features of Automatic Concrete Column Forming Machine:

• One machine can make one slab lower cost, high Wear-resistant, long service life.

• Provide technical support for free.

• Provide consumers with regular visits

• Simple structure, easy operate, less wear parts

3. Automatic Concrete Column Forming Machine Images:

4. Prefabricated Concrete Purline Compression Molding Machine Specification:

Product name | Type | Productivity | Hole number |

Concrete purline machine | 60*120*140* | 1.3-1.5m/min | 4 |

Concrete purline machine | 60*130*150*4 | 1.3-1.5m/min | 4 |

Concrete purline machine | 60*140*160*4 | 1.3-1.5m/min | 4 |

Concrete purline machine | 70*150*170*2 | 1.3-1.5m/min | 2 |

Concrete purline machine | 80*160*180*2 | 1.3-1.5m/min | 2 |

Concrete purline machine | 60*110*130*4 | 1.3-1.5m/min | 4 |

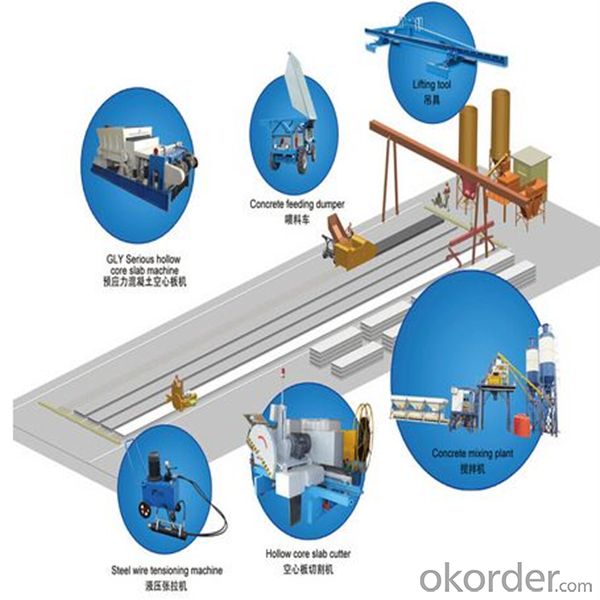

Production Line Layout

Process Flow

Certificates

5. Packing & Delivery

• Wire cables are used for fastening the machine on the trailer or inside the container.

• Machine covered with plastic film.

• Machines can be packed in tarpaulin or wooden case according to customer’s needs.

6. FAQ:

We have organized several common questions for our clients, may help you sincerely:

• What information we need to confirm with you before send a formal offer?

What kind of slab you want to make, wall panel, roof panel, lintel or something else?

Do you have exact slab size (slab thickness and width)? If not, please tell us the slab span, we will give you suggestion.

• Have you use this kind of machine before?

Our machine is totally different from European machine. Please don’t follow their instructions.

• How long can we receive the product after purchase?

In the purchase of product, within 20 working days we will arrange the factory delivery as soon as possible. The specific time of receiving is related to the state and position of customers. Commonly 35 working days can be served.

• What kind of machine do you have?

Our main products: large span GLY concrete hollow core slab machine, light - weight wall panel machine, lintel machine, column machine, hollow core slab cutting machine, concrete feeding dumper, high-strength steel wire tensioning machine, which amount to more than the types and more than four hundred standards. We can provide the whole plan and technology supporting for concrete precast component.

7. Why choose us:

• 30 years manufacturing experience.

• Constitutor of the <Chinese Prestressed Concrete Hollow Core Slab Standard>

• More than 10 patents.

• Passed ISO9001:2000 quality system certificate.

• More than 10 types of machine and over 100 models for choose.

• Supply complete set of technology and equipment solution.

• We can design and manufacture all kinds of concrete forming equipment according to customers' demands. Meanwhile we can even more provide our customers a complete set of technology and solution for all producing flow.

8. Our Service:

• We supply the technical supporting all the time.

• We supply one year warranty for whole machine.

• We supply free quick wear parts.

• We supply low charge continue maintenance when warranty is expired.

• We supply free training to end-users

- Q:can you give me the reviewer for electric machinery by fizgerald (5th ed) pls...?

- Magic Eight Ball says... “Yes - definitely.”

- Q:electric digram for desel generator wih 105 kva

- Call or write to the manufacturer.

- Q:Payback: Quebec, Inc., is purchasing machinery at a cost of $3,768,966. The company expects, as a result, cash flows of $979,225, $1,158,886, and $1,881,497 over the next three years. What is the payback period?

- Plugging okorder /

- Q:i've been working out on my arms for 6 months now but can't seem to get any results on the sides of my upper arms.i'm not really skinny,i'm avarage body build but i have skinny arms.i can grow muscle on front and back of my arms,but not on the sides.what are some good exercises,exercise machinery or techniques i can use to target these areas?(and sorry i don't know the technical names for these muscles in the arm)

- mattress of nails by utilising alice cooper sledgehammer by utilising peter gabriel huge undesirable John by utilising jimmy dean, confident, the sausage guy. LOL The God that failed by utilising metallica cock the hammer by utilising cyprus hill

- Q:Plural form of machine is machines or machinery?

- Machines

- Q:machinery purchsed entry and derpeciation charged for it?

- The purchase: Dr. Machinery (Fixed Assets) Cr. Cash / Accounts Payable Depreciation: Dr. Machinery Depreciation Expense Cr. Machinery Accumulated Depreciation Note that the accumulated depreciation is a contra account for the fixed assets, and what appears on the Balance sheet is the net of the two figures.

- Q:Any manufacturers or suppliers give the details of above matter in India

- Here's okorder /

- Q:Looking at their lists of duties, it seems MR's are machinists, and MM's repair machines/pipes, etc.

- MR What they do The duties performed by MRs include: ? repairing and operating auxiliary machinery; ? calculating time and material needed for machine shop work and the repairing of auxiliary machinery; ? drawing sketches and preparing specifications for replacement parts; ? working from sketches and specifications to produce replacement parts; ? operating machine shop equipment, such as lathes, drill presses, shapers, bench grinders, milling machines, boring mills, power hacksaws and computer numerically controlled machinery; ? working with precision measuring instruments such as micrometers, depth gauges, verniers, calipers, gauge blocks, protractors and dial indicators; ? engraving metal and other materials; ? performing electroplating and flame spraying operations. --------------------------------------... MM What They Do The duties performed by MMs include: ? aligning piping systems for oil, water, air and steam, and controlling the operation of ship boilers and steam turbines used for ship propulsion and service systems; ? controlling operation of turbo generators used to produce electrical power; ? cleaning, adjusting, testing and performing other preventive maintenance on a ship's boilers, main engines, turbo generators and other auxiliary machinery including steering engines, elevators, winches, pumps and associated valves; ? operating and maintaining desalinization plants (distilling plants) to make fresh water from sea water; ? maintaining refrigeration plants, air conditioning systems and galley equipment; ? repairing or replacing valves, pumps, heat exchangers, compressors, steam turbines and hydraulic or pneumatic control devices; ? making entries in and analyzing machinery operating records and reports. --------------------------------------... You should be able to see the difference in primary duties.

- Q:What kind of materials can EDM machine

- Theoretically, any conductive material can be machined with a wire EDM machine.

- Q:I am planning to setup a juice processing unit and therefore need help and info on the plant and machinery either on turnkey basis or upfront selling along with technology transfer.

- I okorder

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Automatic Concrete Column Forming Machine

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 5 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords