Automatic Blow Moulding Machine for 5 Gallon PC Barrel

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 4 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Automatic Blow Moulding Machine for 5 Gallon PC Barrel

5 Gallon PC Barrel Automatic Blow Moulding Machine Production Line Feature:

Reasonable equipment design, compact construction, simple operation

Equipment with high degree automatic, cost less expenses

Electrical equipment, Hydraulic system, Seal parts and Lubrication system adopt the components of famous factory in the world, with low failure rate.

To achieve the best quality guarantee, no matter the appearance and internal, automaticblow moulding machine rate of quality goods is above 99%.

5 Gallon PC Barrel Automatic Blow Moulding Machine Technical Characteristic:

5 Gallon PC Barrel Automatic Blow Moulding Machine adopt European technology, control the hydraulic system with pressure and flow double proportion. The speed of pressure can adjust nonpolarly, high stability, exchange control the electrical system with man-machine interface. Operating surface has a machinery safety configuration, two electrical safety configuration to ensure the safety of operators.

PLC+touch screen, making the operation easy. Automatic malfunction alarm with selfdiagnosis, making the malfunction clear at a glance.

Center input die head, eliminating the knit line completely and making it easy to change the material and color.

Double linear rolling motion guider in moving, opening and closing mold, making the clamping force equally distributed, so the cut is smoother.

Control the hydraulic system with imported proportional valve, ensuring the action steady, accurate and energy saving.

High speed and efficient plasticizing system, mixing well and ensuring the produce purity.

5 Gallon PC Barrel Automatic Blow Moulding Machine Parameter:

Specifications | Unit | Parameters |

Max container capacity | L | 20 |

Extruder System |

|

|

Screw Diameter | mm | 82 |

Screw L/D ratio | L/D | 30:1 |

Screw Speed | rev. / min. | 10~50 |

Plasticizing Capacity | Seconds/die. | 60 |

Number of heating zone barrel | zone | 5 |

Extruder driving Power of barrel | KW | 34 |

Max Injection quantity | L | 1.5 |

Die Head |

|

|

Max die diameter | mm | 130 |

Number of heating zone | zone | 4 |

Extruder driving power | KW | 8.7 |

Clamping Device |

|

|

Platen Size(WxH) | mm | 440 x 600 |

Platen opening stroke | mm | 330~780 |

Clamping force | KN | 210 |

Next blowing Device |

|

|

Blowing the head off and landing trip | mm | 120 |

Manual control Blowing the head off and landing trip | mm | 80 |

Manipulator |

|

|

Take pieces of travel | mm | 1000 |

Framework |

|

|

Lift travel | mm | 250 |

Hydraulic System |

|

|

Rated pressure of big pump | Mpa | 14 |

Rated flow of big pump | L/min | 180 |

Motor power of Hydraulic pumps | KW | 45 |

Parison Controlling Of Hydraulic Servo System |

|

|

Rated pressure | Mpa | 6 |

Rated Flow | L/min | 22 |

Motor power of Hydraulic pumps | KW | 4 |

Pneumatical System |

|

|

Air source pressure | Mpa | 1 |

Working pressure | Mpa | 0.8 |

Air consumption | M3 / min. | 0.6 |

Electrical Control System |

|

|

Water Supply |

|

|

Water supply pressure | Mpa | 0.3 |

Power Supply | ||

Voltage | V | AC380V±10% |

Frequency | HZ | 50 |

Wire |

| 3Phase |

Total of rated power | KW | 91.7 |

Average power consumption | KW.h | 45 |

Total weight | Ton | 11 |

Dimension of machine (Lx W x H) | m | 5.3×2.7×4.5 |

5 Gallon PC Barrel Automatic Blow Moulding Machine Parts Picture:

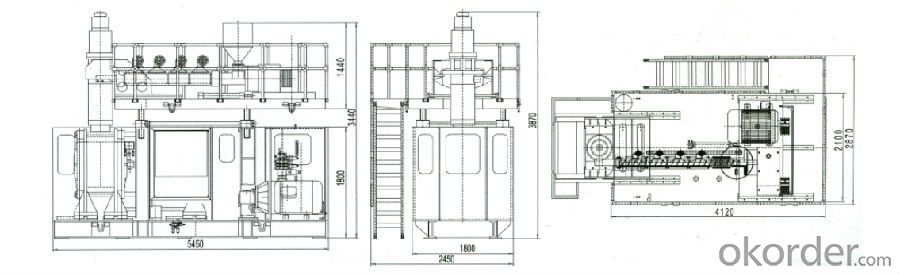

5 Gallon PC Barrel Automatic Blow Moulding Machine Drawing Picture:

5 Gallon PC Barrel Automatic Blow Moulding Machine Electrical Parts Photo:

5 Gallon PC Barrel Automatic Blow Moulding Machine Products Photo:

- Q:Which is the best vacuum oil filter?

- Selection of good oil filter manufacturers, if the budget is abundant, must be good brand, good quality, good after-sales company to buy, although the high prices, but with ease, little problems. If the budget is not enough, then you need to compare by Baidu search or other platforms. Compare your company's size, technical level, quality, after-sale reputation, user success stories, etc., and combine your budget options

- Q:What are the types of oil filters? Oil filter?

- The first generation centrifuge uses centrifugal action to remove impurities and not to remove water. Second generation plate and frame oil filter, filter cloth, filter paper, water removal, large particles, impurities,

- Q:Which is more advantageous than a centrifugal oil filter and a vacuum oil filter?

- The new centrifugal oil filter can also add other technical functions, so as to achieve complex functions, such as increasing the filter core, improving the filter precision of the centrifugal oil filter, and meeting the requirements of higher filtration.

- Q:What is the working principle of the oil filter?

- Which creates a driving force for the high-speed rotation of the rotor. Its speed can reach more than 4000-6000r.p.m, the power generated by the gravity of more than 2000 times, the principle of centrifugal force directly drive impurities from the oil in the separation.

- Q:Want to produce oil filter, that is to filter the hydraulic oil machine. I don't know. Is that ok? The accuracy can reach 2 microns, 5 microns, 10 microns, 20 microns, 40 microns, please

- You do not come to muddy the waters. Now, the industrial transformation and upgrading, Chinese oil filter most of the company will die, not enough strength small manufacturers don't want to die, playing the price war, would not live

- Q:The first filter is not clear! Very cloudy! The second time is almost enough! Does it still have anything to do with temperature? The filtered peanut oil! The virgin oil, which has just been squeezed out of the machine, has not been filtered by vacuum!

- Salt water and sludge are thrown to the wall, and out of the net oil, with centrifugal filtration, the first temperature must be 80 degrees for the best

- Q:How can I get rid of the cooking oil and the sediment filtered out by centrifugal oil filters?.

- After filtration of edible oil and sediment, you can add a ladle in the oil filter (number), so as not to export the filtered oil dirty and precipitation.

- Q:How much is the optimum temperature for cooking oil in a centrifugal oil filter?

- 70-80 degrees is the best filter temperature, and I hope to help you!

- Q:Pneumatic oil filter is slow, isn't it too low?

- Strong magnetic mainly adsorption iron elements, other impurities mainly through the filter block, once the interception of impurities is too much, blocking the filter, on the one hand

- Q:Disadvantages of centrifugal oil filter

- The filter oil has better effect and faster speed. For low temperature, cold oil, the effect is not good. I hope my answer can help you.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Automatic Blow Moulding Machine for 5 Gallon PC Barrel

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 4 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords