Automatic Blow Molding Machine for 5 Gallon PC Bucket

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 4 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Automatic Blow Molding Machine for 5 Gallon PC Bucket

5 Gallon PC Bucket Automatic Blow Molding Machine Production Line Feature:

Reasonable equipment design, compact construction, simple operation

Equipment with high degree automatic, cost less expenses

Electrical equipment, Hydraulic system, Seal parts and Lubrication system adopt the components of famous factory in the world, with low failure rate.

To achieve the best quality guarantee, no matter the appearance and internal, automaticblow molding machine rate of quality goods is above 99%.

5 Gallon PC Bucket Automatic Blow Molding Machine Technical Characteristic:

5 Gallon PC Bucket Automatic Blow Molding Machine adopt European technology, control the hydraulic system with pressure and flow double proportion. The speed of pressure can adjust nonpolarly, high stability, exchange control the electrical system with man-machine interface. Operating surface has a machinery safety configuration, two electrical safety configuration to ensure the safety of operators.

PLC+touch screen, making the operation easy. Automatic malfunction alarm with selfdiagnosis, making the malfunction clear at a glance.

Center input die head, eliminating the knit line completely and making it easy to change the material and color.

Double linear rolling motion guider in moving, opening and closing mold, making the clamping force equally distributed, so the cut is smoother.

Control the hydraulic system with imported proportional valve, ensuring the action steady, accurate and energy saving.

High speed and efficient plasticizing system, mixing well and ensuring the produce purity.

5 Gallon PC Bucket Automatic Blow Molding Machine Parameter:

Specifications | Unit | Parameters |

Max container capacity | L | 20 |

Extruder System |

|

|

Screw Diameter | mm | 82 |

Screw L/D ratio | L/D | 30:1 |

Screw Speed | rev. / min. | 10~50 |

Plasticizing Capacity | Seconds/die. | 60 |

Number of heating zone barrel | zone | 5 |

Extruder driving Power of barrel | KW | 34 |

Max Injection quantity | L | 1.5 |

Die Head |

|

|

Max die diameter | mm | 130 |

Number of heating zone | zone | 4 |

Extruder driving power | KW | 8.7 |

Clamping Device |

|

|

Platen Size(WxH) | mm | 440 x 600 |

Platen opening stroke | mm | 330~780 |

Clamping force | KN | 210 |

Next blowing Device |

|

|

Blowing the head off and landing trip | mm | 120 |

Manual control Blowing the head off and landing trip | mm | 80 |

Manipulator |

|

|

Take pieces of travel | mm | 1000 |

Framework |

|

|

Lift travel | mm | 250 |

Hydraulic System |

|

|

Rated pressure of big pump | Mpa | 14 |

Rated flow of big pump | L/min | 180 |

Motor power of Hydraulic pumps | KW | 45 |

Parison Controlling Of Hydraulic Servo System |

|

|

Rated pressure | Mpa | 6 |

Rated Flow | L/min | 22 |

Motor power of Hydraulic pumps | KW | 4 |

Pneumatical System |

|

|

Air source pressure | Mpa | 1 |

Working pressure | Mpa | 0.8 |

Air consumption | M3 / min. | 0.6 |

Electrical Control System |

|

|

Water Supply |

|

|

Water supply pressure | Mpa | 0.3 |

Power Supply | ||

Voltage | V | AC380V±10% |

Frequency | HZ | 50 |

Wire |

| 3Phase |

Total of rated power | KW | 91.7 |

Average power consumption | KW.h | 45 |

Total weight | Ton | 11 |

Dimension of machine (Lx W x H) | m | 5.3×2.7×4.5 |

5 Gallon PC Bucket Automatic Blow Molding Machine Parts Picture:

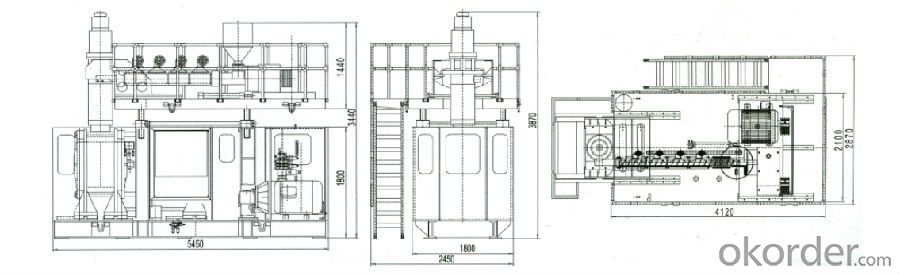

5 Gallon PC Bucket Automatic Blow Molding Machine Drawing Picture:

5 Gallon PC Bucket Automatic Blow Molding Machine Electrical Parts Photo:

5 Gallon PC Bucket Automatic Blow Molding Machine Products Photo:

- Q:What's the difference between a purifier and an oil purifier? Or the purifier is the oil filter

- In addition to the impurities in the oil, the purifier can also separate the moisture in the oil. The oil filter is only a simple filtration of impurities.

- Q:What is the difference between an oil filter and an edible oil refinery? Is it the same device? How about the price? Is it a big difference? I want to buy one useful,Good to Luhua peanut oil level. Please give me your advice. Thank you very much.

- The processed oil can go directly to supermarkets and sell in batches. A set of edible oil refining equipment ranges from tens to hundreds of millions.

- Q:Why is the gas filter not clean?

- Secondly, there is a problem with the oil filter itself. If the filter is not clean, please sell it to your company,

- Q:How to assemble and disassemble the vacuum pump for power generation oil filter?

- After the warranty period if you can point out the money and allow them to install, if they don't want to come, let them call instruction, could not provide service, customer service, customer service service are not even, such companies also want to do

- Q:What kind of oil filter is mainly used in the industry? What are the main uses?

- Sediment corrosion surface mechanical oil filter is mainly used in petrochemical, mining machinery, ship steel, metallurgy medicine, aviation power, if it is edible oil filter also can be used in food industry, general industry, oil filter is a derivative of the industry, as long as the use of oil, whether it is edible oil or industrial if you want to filter oil, oil filter can be used.

- Q:Who knows what the vibration of the oil filter is?

- You are welcome. We will do our best to help you with the oil filter. We will be the manufacturer of the oil filter

- Q:Difference between low speed and high speed of centrifugal oil filter

- High speed centrifuge is the main filtration principle of centrifugal oil filter of the centrifugal force generated, so as to realize oil-water separation and oil separation

- Q:What is the principle of vacuum oil filters used in steam turbines?

- PX is the use of physical means, without affecting the moisture, impurity and gas contains a large number of rapid removal of oil oil components and the premise of the performance of the liquid (acetylene, hydrogen, methane and other harmful ingredients; etc.) can have on steam, Water Leakage, aging, acid, foam, emulsified oil product purification. The quality indexes of the oil products meet the requirements of the quality standard of turbine oil in operation of GB/T 7596-2008

- Q:What are the oil filters for? What are they used for?

- The lubricating system is filtered through the oil filter system to filter the impurities and moisture,

- Q:What is the working principle of the vacuum oil filter?It's easy to understand

- In the filter to filter out large particles of impurities in oil, but can not filter out the compound emulsion regeneration and oxide molecular structure, often need to pay attention to clean the filter in the process of using, easily broken or blocked.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Automatic Blow Molding Machine for 5 Gallon PC Bucket

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 4 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords