Auto-Climbing bracket ACB100 & ACB50

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Auto-climbing Bracket ACB100 & ACB50

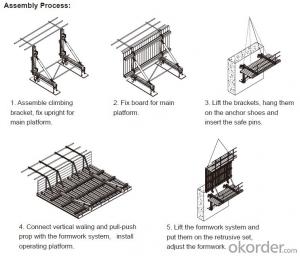

The power of the auto-climbing formwork is the hydraulic system, which includes the oil cylinder

and two commutators. The commutators can control the climbing of climbing rail and the bracket.

The steel rail and the bracket can inter-climbing, so the whole system will climb up steadily.

Cranes are not needed during the construction. It’s easy to operate, highly efficient and safe. It’s

the best choice for the construction of high buildings and bridges.

There are mainly two types of standard auto-climbing brackets, ACB-50 and ACB-100, the figure

means the push power of cylinder with unit of KN.

Characteristics:

◆ Perfect load bearing anchor system

Anchor system is the most important supporting part. The system is made of five parts shown

below. Thereinto, tensile bolt, V-climbing cone and washer can be taken out for reusing after the

concrete pouring finished.There are two kinds of anchor systems,A & B. A is matched with single

anchor shoe and B is matched with double anchor shoe.

◆ Crane-independent

Crane-independent forming, striking and climbing speeds up the work procedures on the

construction site and also makes them independent of each other. This means the planned

sequences can be maintained along with guaranteeing high productivity levels. The crane can

therefore be used for other tasks.

Hydraulic system is mainly made of two commutators,

oil cylinder and power distribution system.The

commutators can control the climbing of climbing rail

and bracket.

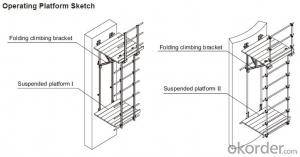

◆ High bearing capacity and safe

The stable working platforms are able to carry large loads, e.g. the storage of reinforcing steel

for the next climbing section. Generously-sized working platforms, the well thought-out design for

handling very high wind loads and the patented control function of the climbing mechanism are

some of the special details contained within the comprehensive safety concept.

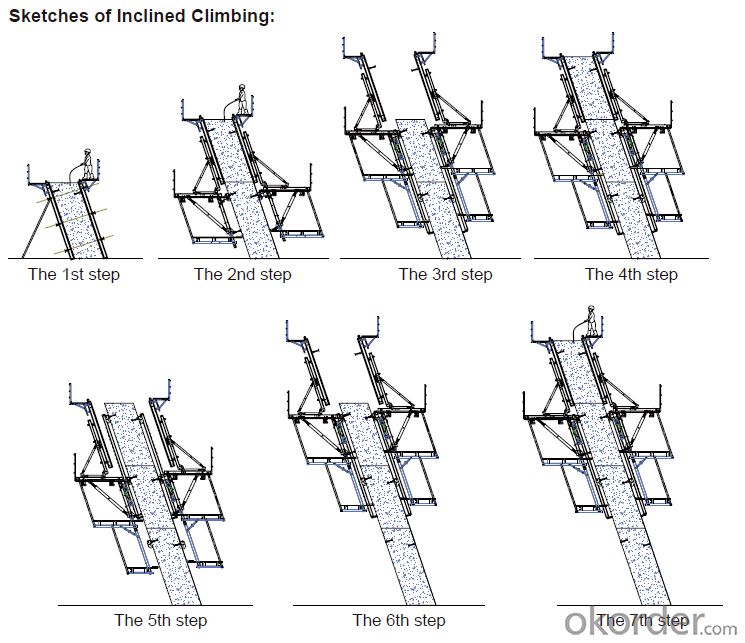

◆ Platforms adjusted to suit the angle of inclination

The horizontal working areas thus created provide safe and comfortable conditions for

reinforcement work, shuttering and striking, concreting and finishing.

◆ The ACB formwork system can climb not only vertically but also slantways, the largest angle is

18 degrees.

◆ The system can climb up wholly or separately. The climbing process is steady, synchronous

and safe.

◆ The bracket will not fall to the ground until the construction is finished, the field will be saved

and the impacting breakage will be reduced (especially the panel).

◆ The system will furnish omnidirectional platform, the construction organizations don’t need to

set up additional operation platform.

◆ The error of structure construction is small and easy to correct.

◆ The climbing speed is fast, the construction course will be quickened.

◆ The formwork can climb itself and cleaning work can be done in the same situs , the used times

of tower crane will be greatly reduced.

- Q:What is the range of adjustment for the full range of scaffolding?

- Adjustable jacking adjustment range within 20cm.

- Q:The permissible range of the top support of the template

- As the current building materials on the market, adjustable top care, adjustable base product specifications vary greatly. Help you brothers, whether there are relevant norms, adjustable top care, adjustable base of the various components from the clear requirements, such as the length of the bolt diameter, steel plate thickness, size and so on. As well as adjustable top care, adjustable use of the base length range.

- Q:Is the car seat with lumbar support adjustable?

- So it is necessary, some seats with adjustment function, may change the support of the level and the thickness of the protrusion. Later can change the seat or change seats, etc., relatively troublesome.

- Q:Yee Jun Edition Octavia with waist support adjustment?

- Used but the effect is not obvious, it is better to buy their own cushions more reliable.

- Q:Scaffolding brace has several models, respectively, can bear the load?

- They are a lot of good quality models of course, bear the strength of the larger

- Q:As the gym did not squat rack, with Smith machine waist twist discomfort, so use the reclining push the practice of squatting, from 40 kg to the current 85 kg. Can this continue to practice it?

- I have seen someone so practice, but with you is the opposite direction, looking at not feel ye, you can talk with the gym, sometimes effective

- Q:What does the car support for the waist?

- Should be placed on the waist of the seat that seat, support the waist, the seat is more comfortable

- Q:JGJ128-2000 door type steel scaffolding specifications only adjustable adjustable screw extension of the base of the relevant provisions of the top of the screw extension of the length of no provisions, but in the specification check the inspection items to check the extension of the screw extension length. What is the standard?

- From the calculation point of view, the end of the care and the top of the extension of the length should be the same, "construction calculation quick manual" seems to have this one of the provisions, as well as the safety of our province continue to re-education on the door scaffolding Textbooks are specified, the top care can be stretched 30CM, but the calculation to be converted, the film coefficient is 0.9, 35c out of the conversion factor is 0.8, out of 40cm, conversion factor is 0.7. Time is longer, the above data is for reference only.

- Q:Car plus a tire pressure detection and waist support adjustment about how much money

- Waist support is best airbag, and now have a manual charge and discharge airbags lumbar 50 yuan

- Q:Support on why there is adjustable support and support the set position, that is, where to put any place can not put?

- JGJ 162-2008, Fasteners for fastener steel scaffolding "JGJ130-2011 has been clearly defined in the template support pole must be set U-type top care. As long as it is to support the pole will put, and adjustable section may not be greater than 200mm.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Auto-Climbing bracket ACB100 & ACB50

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords