ASTM Standard 200,300,400 Series Stainless Steel Sheet/Plate

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 150000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

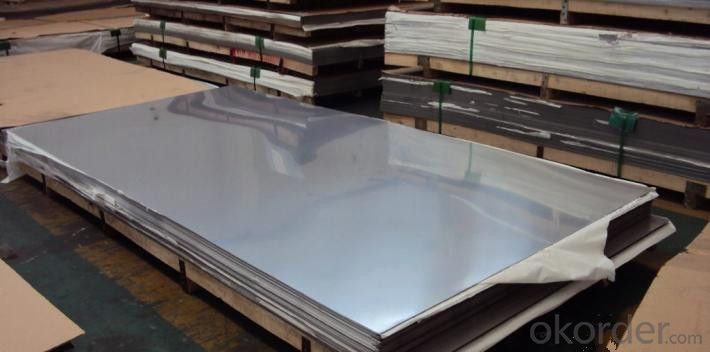

ASTM Standard 200,300,400 stainless steel sheet /Plate

1.Product introduction

We are the manufacturer! We produce stainless steel products with high quality & very competitive price!Please feel free to contact us for more information! | |

Product Name | ASTM Standard 200,300,400 Series Stainless Steel Sheet/Plate |

Standard | JIS AISI ASTM GB DIN |

Grade | 200/300/400 Series |

Thickness | 0.2mm-100mm |

Width | 100mm-2000mm |

Length | According to clients’ requirement |

Surface Finish | 2B ,BA ,8K ,NO4,NO2, NO1 ,Hair line ,EMBOSSED... |

Technique | Cold rolled ,Hot rolled |

Package | Seaworthy packing or as the consumers’ demand |

Application | Be used in manufacture of medical equipment, auto parts, heat-resistant kitchen utensils, electrical accessories , construction decoration ,etc |

Trade Term | FOB CIF |

Payment | T/T , L/C |

LoadingPort | Shanghai |

Delivery Time | 3-7days,mainly in accordance with the quantity |

Report | Material report ,Mechanical performance report |

Certification | ISO9001 |

2.Surface finishes and characteristic

Surface finish | Characteristics and application |

NO.2B | The surface brightness and flatness of no2B is better than no2D. then through a special surface treatment to improve its mechanical properties,No2B could nearly satisfy comprehensive uses. |

NO.1 |

The surface is finished by heat treatment and pickling or processes corresponding thereto after hot rolling.

|

NO.4 | Polished with abrasive belt of grit #150-#180,have better brightness with discontinuous coarse stria,but thinner than No3, are used as bathtub buildings inner and external ornaments electrical appliances kitchen utensils and food processing equipment etc. |

HL | Polished with abrasive belt of grit #150-#320 on the NO.4 finish and has continuous streaks, mainly used as buildings ornaments elevators,door of building, frontal plate etc. |

BA | Cold rolled, bright annealed and skin-passed, the product have excellent brightness and good reflexivity like mirror,kitchen apparatus,ornament etc. |

8K | The product have excellent brightness and prefer reflexivity can to be the mirror. |

Know more about trade...

Payment term: 1. 30% T/T in advance, and the balance against B/L copy

2. 100% irrevocable LC at sight.

Shipment date: Within 15-20 days after advance payment or receipt of LC

Trade term: 1. FOB Shanghai port, China.

2. CIF Discharging port

Guarantee& Service: Mill Test Certificate is supplied with shipment, and Third Part Inspection is acceptable.

Packing: standard export packing (plastic package to prevent water or plywood case to strengthen package)

- Q:What are the different types of stainless steel bars used in power generation?

- There are several types of stainless steel bars commonly used in power generation applications. These include: 1. Austenitic stainless steel bars: These bars are highly corrosion resistant and have excellent mechanical properties. They are often used in power generation equipment that is exposed to high temperatures and corrosive environments, such as heat exchangers and boilers. 2. Martensitic stainless steel bars: Martensitic stainless steel bars have high strength and hardness. They are commonly used in power generation applications where strength and durability are critical, such as turbine blades and shafts. 3. Duplex stainless steel bars: Duplex stainless steel bars have a combination of austenitic and ferritic microstructures, which gives them improved strength and corrosion resistance. They are often used in power generation equipment that is exposed to both high temperatures and corrosive environments, such as condensers and pumps. 4. Ferritic stainless steel bars: Ferritic stainless steel bars have good corrosion resistance and high-temperature strength. They are commonly used in power generation applications where resistance to oxidation and scaling is important, such as furnace parts and exhaust systems. 5. Precipitation hardening stainless steel bars: These bars are heat treatable and offer a combination of high strength and corrosion resistance. They are often used in power generation equipment that requires high strength and resistance to stress corrosion cracking, such as turbine discs and compressor blades. Overall, the choice of stainless steel bars in power generation depends on the specific application and the required properties, such as corrosion resistance, strength, and high-temperature resistance. It is important to select the appropriate stainless steel grade to ensure optimal performance and longevity of the equipment used in power generation processes.

- Q:Are stainless steel bars resistant to phosphoric acid corrosion?

- Yes, stainless steel bars are generally resistant to phosphoric acid corrosion.

- Q:Are stainless steel bars resistant to acids and chemicals?

- Yes, stainless steel bars are generally resistant to acids and chemicals. Due to their high chromium content, stainless steel bars form a protective layer that prevents corrosion and degradation when exposed to acids and various chemicals. However, the level of resistance can vary depending on the specific grade and concentration of the acid or chemical involved. It is advisable to consult the manufacturer or reference material compatibility charts to ensure the appropriate stainless steel grade is selected for specific applications.

- Q:What are the different types of surface finishes for stainless steel bars?

- There are several types of surface finishes for stainless steel bars, including mill finish, brushed finish, polished finish, and satin finish. The mill finish is the standard finish and has a dull appearance. Brushed finish creates a textured look with parallel lines. Polished finish provides a mirror-like shine, while satin finish offers a smooth, matte appearance.

- Q:Can stainless steel bars be used in high-temperature environments?

- Yes, stainless steel bars can be used in high-temperature environments. Stainless steel is known for its excellent heat resistance properties, making it suitable for applications where exposure to high temperatures is expected. The alloying elements in stainless steel, such as chromium and nickel, provide enhanced resistance to oxidation and corrosion, enabling it to retain its strength and structural integrity even at elevated temperatures. Additionally, stainless steel bars can withstand thermal cycling without significant deformation or deterioration, making them a reliable choice for high-temperature environments.

- Q:What are the pricing factors for stainless steel bars?

- The pricing factors for stainless steel bars can vary depending on several key factors. Firstly, the grade of stainless steel used in the production of the bars plays a significant role in determining the price. Different grades of stainless steel have varying levels of corrosion resistance, strength, and durability, which can impact the cost. Additionally, the size and dimensions of the stainless steel bars also influence the pricing. Bars with larger diameters or lengths are generally more expensive due to the increased material required for their production. Market demand and supply conditions also impact the pricing of stainless steel bars. Fluctuations in global demand for stainless steel, as well as the availability of raw materials, can influence the overall cost. Furthermore, the manufacturing process and associated production costs contribute to the pricing. Factors such as the complexity of production techniques, energy consumption, labor costs, and overhead expenses are considered when determining the final price of stainless steel bars. Lastly, any additional treatments or finishes applied to the bars, such as polishing or surface coatings, can affect the pricing. These treatments enhance the aesthetic appeal or provide additional protection to the stainless steel, thereby increasing the overall cost. Considering these factors collectively, it is essential to carefully evaluate the grade, size, market conditions, manufacturing process, and any additional treatments to determine the pricing of stainless steel bars.

- Q:Can stainless steel bars be used in the agricultural industry?

- Yes, stainless steel bars can be used in the agricultural industry. Stainless steel is a versatile and durable material that offers several benefits for agricultural applications. It is resistant to corrosion, which is particularly useful in environments with high moisture content or exposure to chemicals and fertilizers. Stainless steel bars can be used in various agricultural equipment, machinery, and infrastructure, such as barns, animal enclosures, gates, fences, and irrigation systems. Additionally, stainless steel bars are easy to maintain, clean, and sanitize, making them suitable for use in food processing and storage facilities within the agricultural industry.

- Q:What is the difference between threaded and non-threaded stainless steel bars?

- Threaded stainless steel bars have threads along their entire length, allowing them to be easily fastened and secured into various structures or components using nuts and bolts. On the other hand, non-threaded stainless steel bars do not have threads and are smooth along their entire surface. This means that they cannot be directly screwed or fastened into place; instead, they are typically used for applications where they need to be welded or otherwise joined with other materials. The choice between threaded and non-threaded stainless steel bars depends on the specific requirements of the project or application. Threaded bars are commonly used in construction, manufacturing, and mechanical engineering industries where the ability to easily secure and adjust the fasteners is crucial. They are often used for structural purposes, such as in the assembly of frameworks, supports, or scaffolding. Non-threaded stainless steel bars, on the other hand, are more commonly used in applications where welding or other joining methods are preferred or necessary. This includes applications in the automotive, aerospace, and marine industries, where the bars may need to be welded to other components or structures. Non-threaded bars are also frequently used as reinforcement in concrete structures, where they are embedded within the concrete to provide additional strength and stability. In summary, the main difference between threaded and non-threaded stainless steel bars lies in their ability to be fastened or joined with other materials. Threaded bars have threads along their entire length, allowing for easy installation with nuts and bolts, while non-threaded bars are typically used in applications where welding or other joining methods are utilized.

- Q:Can stainless steel bars be used in paper production machinery?

- Indeed, the utilization of stainless steel bars in paper production machinery is viable. Renowned for its remarkable resistance to corrosion and durability, stainless steel emerges as an optimal material across diverse industries, including the paper sector. Stainless steel bars serve the purpose of securing, directing, or bolstering various components within paper production machinery. Moreover, the cleaning and maintenance of stainless steel bars are effortless, while their ability to endure elevated temperatures and harsh chemicals commonly employed in the paper production process is noteworthy. Consequently, selecting stainless steel bars assures the uninterrupted functionality and prolonged lifespan of paper production machinery.

- Q:Can stainless steel bars be used in construction applications?

- Indeed, construction applications can make use of stainless steel bars. Stainless steel, known for its strength and durability, boasts exceptional resistance to corrosion, rendering it ideal for diverse construction endeavors. These bars find common employment in constructing frameworks, bridges, staircases, and reinforcement structures. Not only do they offer structural support and withstand substantial loads, but they also guarantee the longevity and stability of the construction. Moreover, stainless steel bars are favored in construction for their aesthetic appeal, as they can be polished to attain a sleek and lustrous finish, thereby enhancing the overall appearance of the project.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

ASTM Standard 200,300,400 Series Stainless Steel Sheet/Plate

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 150000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords