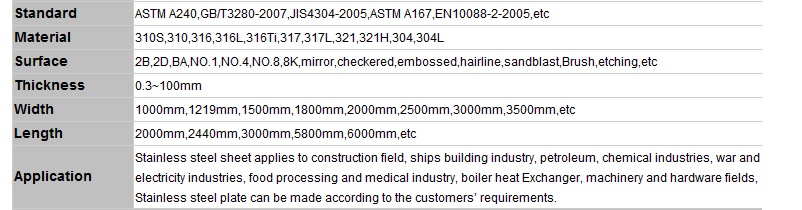

ASTM Competitive price hot rolled 316l stainless steel plate

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 kg

- Supply Capability:

- 1000 kg/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

- Q:What is the difference between 17-4PH and 15-5PH stainless steel pipes?

- The chemical composition and mechanical properties are the main factors that distinguish 17-4PH and 15-5PH stainless steel pipes. Regarding 17-4PH stainless steel, it is a precipitation-hardening grade that comprises 17% chromium, 4% nickel, 4% copper, and a small amount of molybdenum. This grade is renowned for its exceptional combination of high strength and resistance to corrosion. Additionally, it can be subjected to heat treatment to achieve varying levels of hardness, making it suitable for diverse applications that necessitate strength and corrosion resistance. On the contrary, 15-5PH stainless steel is also a precipitation-hardening grade but possesses a slightly different composition. It consists of 15% chromium, 5% nickel, and 3-5% copper. This grade offers good strength, toughness, and corrosion resistance, comparable to 17-4PH stainless steel. However, it exhibits a higher level of toughness and better resistance to stress corrosion cracking. In terms of mechanical properties, 17-4PH stainless steel generally exhibits greater strength and hardness compared to 15-5PH stainless steel. It can be subjected to heat treatment to achieve a wide range of hardness levels, including high strength and hardness suitable for demanding applications. On the other hand, 15-5PH stainless steel, although still possessing good strength, typically does not undergo the same extent of heat treatment as 17-4PH. Both 17-4PH and 15-5PH stainless steel pipes find common usage in industries such as aerospace, oil and gas, and chemical processing, where their combination of strength and corrosion resistance proves highly advantageous. The choice between the two grades depends on specific application requirements, with 17-4PH offering greater strength and hardness versatility, while 15-5PH provides better resistance to stress corrosion cracking and improved toughness.

- Q:Are stainless steel pipes suitable for underground drainage systems?

- Yes, stainless steel pipes are suitable for underground drainage systems. Stainless steel is highly durable, resistant to corrosion, and has a long lifespan, making it an excellent choice for underground applications where the pipes may be exposed to moisture, chemicals, and other harsh conditions. Additionally, stainless steel pipes offer high strength and are capable of withstanding heavy loads, making them a reliable option for underground drainage systems.

- Q:Stainless steel pipe specification 25*2 what does it mean?

- Outside diameter 25MM, wall thickness 2MM, this tube is too thick, our company has thin wall stainless steel tube

- Q:What are the advantages of using stainless steel pipes in the oil and gas industry?

- There are several advantages of using stainless steel pipes in the oil and gas industry. 1. Corrosion resistance: Stainless steel pipes are highly resistant to corrosion, making them ideal for transporting oil and gas. They can withstand extreme temperatures, harsh chemicals, and corrosive environments, ensuring long-term durability and preventing costly repairs or replacements. 2. Strength and durability: Stainless steel pipes have high tensile strength, which means they can withstand heavy loads and high-pressure environments. This characteristic makes them suitable for transporting oil and gas over long distances, as they can handle the required stress without compromising their structural integrity. 3. Hygienic and clean: Stainless steel pipes are non-porous and have a smooth surface, making them resistant to bacterial growth and minimizing the risk of contamination. This is crucial in the oil and gas industry, where maintaining the purity and quality of the transported fluids is paramount. 4. Heat resistance: Stainless steel pipes can handle high temperatures without deformation or degradation. They are capable of withstanding the extreme heat generated during the extraction, refining, and transportation processes in the oil and gas industry. 5. Flexibility and adaptability: Stainless steel pipes can be easily modified or customized to meet specific requirements. They can be welded, bent, or shaped into various configurations without compromising their strength or integrity. This flexibility allows for efficient installation and reduces the need for additional connectors or fittings. 6. Longevity and cost-effectiveness: Stainless steel pipes have a long lifespan, often exceeding 50 years, when properly maintained. This longevity reduces the frequency of replacements and repairs, minimizing downtime and overall costs in the oil and gas industry. 7. Environmental sustainability: Stainless steel is a highly recyclable material, making it an environmentally friendly choice. When stainless steel pipes reach the end of their life cycle, they can be easily recycled and used to manufacture new products, reducing waste and conserving resources. In summary, the advantages of using stainless steel pipes in the oil and gas industry include corrosion resistance, strength and durability, hygienic and clean properties, heat resistance, flexibility and adaptability, longevity and cost-effectiveness, as well as environmental sustainability. These benefits make stainless steel pipes a reliable and efficient choice for transporting oil and gas, ensuring the integrity and safety of the operations.

- Q:Can stainless steel pipes be welded to other materials?

- Yes, stainless steel pipes can be welded to other materials. However, it is important to consider the compatibility of the materials being welded together and ensure proper welding techniques are used to achieve a strong and reliable joint.

- Q:Can stainless steel pipes be used for vacuum systems?

- Indeed, vacuum systems can utilize stainless steel pipes. Owing to its exceptional strength, resistance to corrosion, and minimal outgassing characteristics, stainless steel is widely favored in vacuum-related endeavors. It has the capacity to endure substantial levels of vacuum while upholding its structural integrity when subjected to pressure. Various industries, including aerospace, semiconductor manufacturing, and scientific research, commonly employ stainless steel pipes to construct their vacuum systems. Moreover, these pipes can be effortlessly cleaned and upheld, rendering them a dependable and enduring choice for vacuum applications.

- Q:What is the difference between 304J4 and 316J4 stainless steel pipes?

- 304J4 and 316J4 are both types of stainless steel pipes, but they differ in terms of their composition and properties. The main difference between 304J4 and 316J4 stainless steel pipes lies in their alloy content. 304J4 stainless steel contains 18-20% chromium and 8-10% nickel, while 316J4 stainless steel contains 16-18% chromium, 10-14% nickel, and 2-3% molybdenum. The higher nickel and molybdenum content in 316J4 stainless steel pipes gives them superior corrosion resistance compared to 304J4 stainless steel pipes. This makes 316J4 stainless steel pipes more suitable for applications where they will be exposed to harsh environments, such as marine or chemical industries. Additionally, the higher molybdenum content in 316J4 stainless steel pipes enhances their resistance to pitting and crevice corrosion, which can occur in chloride-rich environments. This makes them a preferred choice for applications involving exposure to seawater or other corrosive substances. On the other hand, 304J4 stainless steel pipes are more cost-effective and are commonly used in less demanding applications where corrosion resistance is not a primary concern. They are widely used in industries such as food processing, appliances, and automotive. In summary, the main differences between 304J4 and 316J4 stainless steel pipes lie in their alloy content and resulting corrosion resistance properties. 316J4 stainless steel pipes offer higher corrosion resistance, particularly in chloride-rich environments, making them suitable for more demanding applications, while 304J4 stainless steel pipes are more cost-effective and commonly used in less corrosive environments.

- Q:What is the yield strength of stainless steel pipes?

- The yield strength of stainless steel pipes is subject to variation based on the specific grade and composition of the stainless steel. Nevertheless, the range of yield strengths for stainless steel pipes typically falls between 30,000 and 100,000 pounds per square inch (psi). It is worth emphasizing that the yield strength signifies the juncture at which the material undergoes permanent deformation due to applied stress. Hence, selecting the suitable grade and thickness of stainless steel pipe is of utmost importance, considering the intended application and the particular mechanical properties deemed necessary.

- Q:Can stainless steel pipes be used for chemical processing applications?

- Stainless steel pipes are a viable option for chemical processing applications. They possess exceptional corrosion resistance, making them suitable for handling a wide range of chemicals and corrosive substances. Their resistance extends to both organic and inorganic chemicals, covering acids, alkalis, and solvents. Moreover, stainless steel pipes exhibit high strength and durability, enabling them to withstand the typically encountered high temperatures and pressures in chemical processing operations. The smooth inner surface of these pipes also prevents the accumulation of deposits, ensuring the efficient flow of chemicals. All in all, stainless steel pipes are a dependable choice for chemical processing applications due to their corrosion resistance, strength, durability, and ease of maintenance.

- Q:What are the common shapes of stainless steel pipes?

- Stainless steel pipes come in various shapes that are widely utilized across different industries. These shapes comprise of round pipes, square pipes, rectangular pipes, and oval pipes. Round pipes rank among the most prevalent shapes and find extensive use in diverse applications. They are primarily employed for fluid and gas transportation, as well as the conveyance of other materials. Furthermore, round pipes are well-suited for structural purposes like handrails, scaffolding, and support beams. Square pipes possess a square cross-section and are commonly employed in construction projects, architectural designs, and furniture manufacturing. They offer a sleek and contemporary appearance, often utilized for framing structures, manufacturing shelves, and creating decorative elements. Rectangular pipes possess a rectangular cross-section and are frequently utilized in the construction, engineering, and manufacturing industries. They are often employed in building frameworks, manufacturing gates, fences, and various structural components. Oval pipes possess an elliptical or oval shape and are used in applications where aesthetics play a significant role. They are a popular choice in architectural designs, the automotive industry, and decorative applications. In conclusion, the selection of stainless steel pipe shape depends on the specific requirements of the application and desired aesthetics. Each shape offers distinct advantages and is chosen based on factors such as strength, durability, ease of fabrication, and overall design requirements.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

ASTM Competitive price hot rolled 316l stainless steel plate

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 kg

- Supply Capability:

- 1000 kg/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products

Hot Searches

Related keywords