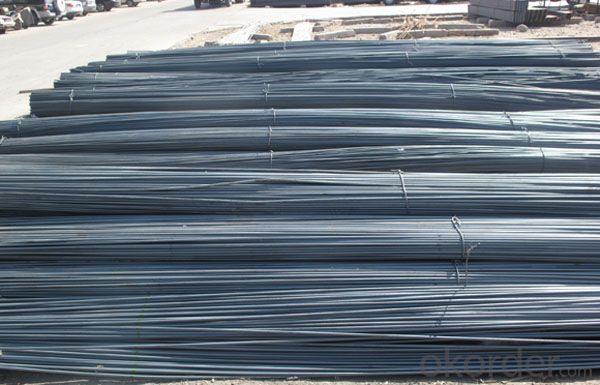

ASTM A615 deformed steel bar for construction

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering ASTM A615 deformed steel bar for construction at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

ASTM A615 deformed steel bar are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's deformed steel bar are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specificati

Hot Rolled Steel Rebar HRB 500B

1.China direct supplier

2.Best service

3.Competitive price

4.Quantity assured

Product Description

| Name | Steel,Hot Rolled Steel Structure,Deformed Steel Bar,China Manufacture H500B 12M |

| Standard | ASTM A615 /BS BS 4449 /GB HRB/ JIS G3112 |

| Grade | HRB500B |

| Diameter | 12mm-40mm |

| Length | 6-12m |

| Technique | Low temperature hot-rolling reinforcing deformed steel rebar |

| Tolerance | As the standard or as your requirement |

| Application | Building, construction, road, bridge,etc |

| Certificated | BV |

| MOQ | 500tons per size steel rebar |

| Packing details | Steel rebar packed in bundle or as your requirement |

| Delivery | Within 30 days after deposit |

| Payment | T/T or L/C |

Chemical Composition

Grade | Technical data of the original chemical composition (%) | |||||||

C | Mn | Si | S | P | V | |||

HRB400 | ≤0.25 | ≤1.60 | ≤0.80 | ≤0.045 | ≤0.045 | 0.04-0.12 | ||

Physics capability | ||||||||

Yield Strength(N/cm2) | Tensile Strength(N/cm2) | Elongation (%)

| ||||||

≥400 | ≥570 | ≥14 | ||||||

Theorectical weight

Diameter (MM) | Cross Sectional Area (MM2) | Theorectical Weight (KG/M) | Weight of 12M Bar (KG) | A Ton Contains 12M Bars (PCS) |

| 6 | 28.27 | 0.222 | 2.664 | 375.38 |

| 8 | 50.27 | 0.395 | 4.74 | 210.97 |

| 10 | 78.54 | 0.617 | 7.404 | 135.06 |

| 12 | 113.1 | 0.888 | 10.656 | 93.84 |

| 14 | 153.9 | 1.21 | 14.52 | 68.87 |

| 16 | 201.1 | 1.58 | 18.96 | 52.74 |

| 18 | 254.5 | 2 | 24 | 41.67 |

| 20 | 314.2 | 2.47 | 29.64 | 33.74 |

| 22 | 380.1 | 2.98 | 35.76 | 27.96 |

| 25 | 490.9 | 3.85 | 46.2 | 21.65 |

| 28 | 615.8 | 4.83 | 57.96 | 17.25 |

| 32 | 804.2 | 6.31 | 75.72 | 13.21 |

| 36 | 1018 | 7.99 | 98.88 | 10.43 |

| 40 | 1257 | 9.87 | 118.44 | 8.44 |

FAQ:

Q1: Can stainless steel rust?

A1: Stainless does not "rust" as you think of regular steel rusting with a red oxide on the surface that flakes off. If you see red rust it is probably due to some iron particles that have contaminated the surface of the stainless steel and it is these iron particles that are rusting. Look at the source of the rusting and see if you can remove it from the surface.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

- Q:Can steel rebars be used in renovation or retrofitting projects?

- Yes, steel rebars can be used in renovation or retrofitting projects. Steel rebars are commonly used in construction projects to reinforce concrete structures, providing strength and durability. In renovation or retrofitting projects, where existing structures need to be strengthened or modified, steel rebars can be utilized to enhance the structural integrity and ensure the safety of the building.

- Q:What is the average lifespan of steel rebars in marine environments?

- Several factors can influence the average lifespan of steel rebars in marine environments. On the whole, these rebars tend to last between 50 and 100 years in such settings. This estimate considers the corrosive properties of saltwater, which can hasten the decay of steel structures. Furthermore, the quality of the steel, the marine structure's design and construction, and maintenance practices can all impact the rebars' lifespan. Regular inspections, the application of protective coatings, and appropriate maintenance can effectively prolong the rebars' longevity in marine environments.

- Q:Can steel rebars be used in retaining wall construction?

- Yes, steel rebars can be used in retaining wall construction. They are commonly used to reinforce concrete walls and provide additional strength and stability to the structure. The rebars are typically embedded within the concrete to prevent cracking and increase the wall's resistance to lateral pressure from the retained soil.

- Q:How do steel rebars affect the fire resistance of concrete structures?

- Concrete structures can greatly increase their ability to withstand fire by incorporating steel rebars. These rebars serve as reinforcement, providing extra strength and stability to the structure and enabling the concrete to endure the intense heat of a fire. The fire resistance of concrete structures primarily relies on the fact that concrete has low thermal conductivity. When exposed to high temperatures, concrete undergoes spalling, where the outer layer breaks off due to the rapid expansion of trapped water. However, the presence of steel rebars helps prevent spalling by holding the concrete together and preventing it from disintegrating. Moreover, steel rebars have a higher melting point than concrete. This means that even when exposed to extreme heat, the rebars maintain their strength and integrity. Consequently, the overall structural stability of the concrete structure remains intact, even in the presence of fire. Steel rebars also act as a heat sink, absorbing and dissipating heat away from the surrounding concrete. This dissipation of heat prevents the formation and spread of localized hotspots throughout the structure, thereby reducing the risk of structural failure. To further enhance the fire resistance of concrete structures, specialized types of steel rebars, known as fire-resistant or fire-rated rebars, can be utilized. These rebars are specifically designed to withstand high temperatures for extended periods without losing their strength. They are often coated with materials such as epoxy or intumescent coatings, which offer additional protection against fire. In conclusion, steel rebars play a vital role in improving the fire resistance of concrete structures. Their presence enhances the overall structural stability, minimizes spalling, dissipates heat, and provides additional strength to withstand the intense heat generated during a fire.

- Q:What are the guidelines for splicing steel rebars in a structure?

- The guidelines for splicing steel rebars in a structure are as follows: 1. Ensure proper design: The first step is to have a detailed design of the structure, which includes the required length and location of rebar splices. The design should follow the applicable building codes and standards. 2. Use approved methods: It is crucial to use approved methods for splicing steel rebars. The most common methods include lap splicing, mechanical splicing, and welded splicing. The selected method should be in compliance with the design requirements and accepted industry practices. 3. Determine splice length: The splice length is determined based on the structural requirements and the type of rebar being used. It is recommended to consult the design engineer or refer to the code requirements to determine the appropriate splice length. 4. Prepare the rebars: Before splicing, rebars should be cleaned of rust, scale, oil, or any other contaminants that may affect the bond strength. The ends of the rebars should be clean and free from deformations or irregularities. 5. Splice location: The location of the splice is critical and should be as per the design specifications. Splices should not be placed in areas subjected to high stress or where they may affect the structural integrity of the member. 6. Reinforcement continuity: Splicing should maintain the continuity of reinforcement to ensure the structural integrity. Adequate overlap or connection strength should be achieved to transfer loads between the spliced rebars. 7. Proper installation: During splicing, it is important to follow proper installation procedures. This may include using appropriate splicing materials, ensuring correct alignment and fit, and applying the recommended torque or tension for mechanical splices. 8. Quality control and inspection: Regular inspections should be conducted during and after the splicing process to ensure compliance with the design and quality standards. This may involve visual inspection, non-destructive testing, or load testing as required. 9. Documentation and record-keeping: It is essential to maintain proper documentation of the splicing process, including details of the method used, splice length, location, and any deviations from the design. This documentation helps in ensuring traceability and accountability. 10. Compliance with codes and standards: Lastly, all splicing activities should comply with the relevant building codes, industry standards, and specifications. It is advisable to refer to the specific code requirements applicable to the region and seek professional advice if needed.

- Q:Can steel rebars be used in corrosive chemical environments?

- Steel rebars can be used in corrosive chemical environments, but their performance and durability may be compromised. Steel is susceptible to corrosion when exposed to certain chemicals, especially those that are acidic or contain chlorides. In such corrosive environments, the rebars can undergo corrosion, leading to structural damage and reduced load-bearing capacity. To mitigate the corrosion risk, various measures can be taken. One common approach is to coat the rebars with a protective layer, such as epoxy or zinc coating, to create a barrier between the steel and the corrosive environment. Additionally, using stainless steel rebars or other corrosion-resistant alloys can provide better resistance against chemical corrosion. It is crucial to consider the specific chemicals present in the environment and consult with corrosion engineers and experts to determine the appropriate measures for using steel rebars in corrosive chemical environments. Proper maintenance and regular inspections are also necessary to monitor any signs of corrosion and take prompt corrective action to ensure the structural integrity and safety of the reinforced concrete structures.

- Q:What are the standards and specifications for steel rebars?

- International organizations such as ASTM and ISO primarily establish the standards and specifications for steel rebars, also known as reinforcing bars. These standards guarantee that steel rebars meet specific requirements for strength, durability, and dimensional accuracy. ASTM A615 is one of the most commonly used standards for steel rebars. It covers deformed and plain carbon-steel bars for concrete reinforcement. This standard sets the minimum yield strength, tensile strength, and elongation properties for various rebars grades, including Grade 40, Grade 60, and Grade 75. It also outlines the mechanical properties, chemical composition, and bending properties of rebars. Aside from ASTM A615, there are other standards that provide specifications for steel rebars. ASTM A706, for instance, focuses on low-alloy steel bars for concrete reinforcement. This standard ensures that rebars possess improved weldability and ductility to withstand seismic forces and other dynamic loads. ISO 15630 is another significant standard that addresses steel for concrete reinforcement. It provides specifications for hot-rolled and cold-worked steel bars, as well as welded fabric and lattice girders. ISO 15630 outlines the mechanical properties, chemical composition, and dimensional tolerances of rebars. Furthermore, regional or national organizations also establish their own standards for steel rebars. For instance, the BSI has developed the BS 4449 standard, which specifies the requirements for carbon steel rebars used in concrete reinforcement in the United Kingdom. Similarly, the ISI has set the IS 1786 standard for cold-twisted steel bars used in concrete reinforcement in India. In conclusion, the standards and specifications for steel rebars ensure that these construction materials possess the necessary strength, ductility, and other properties required for reinforcing concrete structures. By adhering to these standards, manufacturers, engineers, and construction professionals can ensure the safety and durability of reinforced concrete projects.

- Q:What are the safety precautions to take when working with steel rebars?

- When working with steel rebars, it is crucial to follow various safety precautions to ensure the well-being of yourself and those around you. Here are some safety measures to consider: 1. Personal Protective Equipment (PPE): Always wear appropriate PPE such as safety goggles, gloves, hard hats, and steel-toed boots to protect yourself from potential hazards like falling objects, cuts, and burns. 2. Training and Awareness: Obtain proper training and be aware of the potential risks associated with working with steel rebars. Educate yourself and your team about the correct procedures and safe handling techniques. 3. Secure Storage: Store steel rebars in a designated area to prevent them from falling or causing accidents. Stack them systematically, ensuring stability and avoiding areas with heavy foot traffic. 4. Lifting Techniques: When lifting steel rebars, use proper lifting techniques such as bending your knees and using your legs to lift rather than your back. Avoid overloading yourself and seek assistance when needed. 5. Handling Tools: Use suitable tools like wire mesh gloves or pliers to handle steel rebars. This prevents injuries caused by sharp edges or splinters. 6. Inspection: Regularly inspect steel rebars for any defects, such as rust or sharp edges, before using them. Damaged or defective rebars should be discarded and replaced. 7. Clear Work Area: Keep the work area organized and free from clutter, ensuring that there are no tripping hazards or obstacles that could cause accidents. 8. Communication: Maintain clear communication with your team members, signaling when moving or handling steel rebars. This helps prevent accidental collisions or injuries. 9. Fire Safety: Be mindful of fire hazards when working with steel rebars. Keep flammable materials away from the work area and have fire extinguishers readily accessible. 10. First Aid: Ensure that a first aid kit is available nearby, and be familiar with basic first aid procedures in case of any accidents or injuries. By following these safety precautions, you can significantly reduce the risk of accidents and injuries while working with steel rebars. Remember, safety should always be a top priority in any work environment.

- Q:How do steel rebars contribute to the overall fire safety of a structure?

- Steel rebars contribute to the overall fire safety of a structure by providing reinforcement and stability to the concrete. They have high melting points, which means they can withstand high temperatures for an extended period of time before losing their strength. This helps prevent the collapse of the structure during a fire, allowing occupants more time to evacuate and firefighters more time to control the blaze.

- Q:Cold drawn steel wire is a round bar or thread steel in Construction Engineering

- Cold drawn steel wire belongs to round bar in building engineering, and it is thread steel after coining. But the material of steel is not good. Who knows what material he made?.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

ASTM A615 deformed steel bar for construction

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords