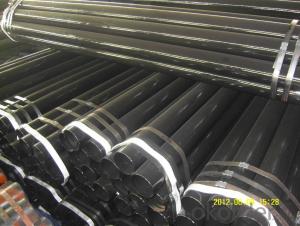

ASTM A 106 GRB cold drawn seamless steel pipe

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

Thickness: | 1 - 80 mm | Section Shape: | Round | Outer Diameter: | 6 - 2020 mm |

Place of Origin: | Shandong China (Mainland) | Secondary Or Not: | Non-secondary | Application: | Oil Pipe |

Technique: | Cold Drawn,Seamless | Certification: | API | Surface Treatment: | Copper Coated |

Special Pipe: | API Pipe | Alloy Or Not: | Is Alloy | Grade: | 20#,45#,15CrMo,10CrMo910,13CrMo44,12Cr2Mo,12CrMo195,12Cr1MoVG,API J55,API K55,St37,St52,St35.8,St37-2,St42-2,10#-45#,Cr-Mo alloy,API J55-API P110,ST35-ST52 |

Standard: | GB 5310-1995,GB 3087-1999,GB/T 8163-1999,GB/T 8162-1999,GB/T 9711.1-1997,GB 13296-2007,GB/T 3091-2001,GB/T 3089-1982,GB/T 17396-1998,GB/T 12771-2000,GB |

Packaging & Delivery

Packaging Detail: | Export packing or as your demand. |

Delivery Detail: | depend on the QTY you need. |

Specifications

cold drawn seamless steel pipes

1)Grade:20#,45#,16Mn C20,C45,St52 A106 A53

2)OD10.3mm--1219mm WT SCH5S--XXS

3)High quality

Standard | Steel Grade | Standard Name | Dimension |

No | Range | ||

EN 10208 | L210GA,L235GA,L245GA,L290GA, | Steel Pipes for Pipelines for | 33.7-1626mm |

L360GA,L245NB, L290NB,L360NB, | Combustible Fluids | ||

L415NB, L360QB, LI15QB,L450QB, | |||

L485QB,L555QB | |||

EN 10210 | S235JRH,S275JOH,S275J2H,S355JOH, | Hot Finished Structural | 21.3-1219mm |

S355J2H,S355K2H,S275NH,S275NLH, | Hollow Sections of Non-alloy | ||

S355NH,S355NLH,S420NH,S420NLH, | and Fine Grain Steels | ||

S46INH,S460NLH | |||

EN 10216-1 | P195TRI,P195TR2,P235TR1, | Seamless Steel Tubes for | 10.2-711mm |

P235TR2, P265TR I, P265TR2 | Pressure Purposes-1- | ||

Non-alloy Steel Tubes with | |||

Specified Room Temperature | |||

Properties | |||

EN 10216-2 | P195GH, P235GH, P265GH, | Seamless Steel Tubes for | 10.2-711mm |

20MnNb6,16Mo3, 8MoB5-4, | Pressure Purposes-2: | ||

14MoV6.3, 10CrMo5.5,13CrMo4-5, | Non-alloy and Alloy Steel | ||

10CrMo9-10, 11CrMo9.10, | Tubes with Specified Elevated | ||

25CrMo4,20CrMoV13-5-5, | Temperature Properties | ||

15 NiCuMoNB-6-4,X11CrMo5+1, | |||

X11CrMo5+NTI,X11CrMo5+NT2, | |||

X11CrMo9.1+1, X11CrMo9.1+NT, | |||

X10CrMoVNb9-l, X20CrNiV11-1 | |||

EN 10216-3 | P275NL I,P275NL2, P355N,P355NH, | Seamless Steel Tubes for | 10.2-711mm |

P355NL1,P355NL2,P460N,P460NH, | Pressure Purposes-3: | ||

P460NL1,P460NL2,P620Q,P620QH,P620QL, | Alloy Fine Grant Steel Tubes | ||

P690Q,P690QH,P690OL1,P690QL2 | |||

EN10216-4 | P215NL,P255QL,P265NL, | Seamless Steel Tubes far | 10.2-711mm |

26CrMo4.2,11MnNi5-3,13MnNi6-3, | Pressure Purposes-4: | ||

12Nil4,Xl2Ni5,X10Ni9 | Non-alloy aid Alloy Steel | ||

Tubes with Specified Low | |||

Temperature Properties | |||

EN 10224 | L235, L275, L355 | Non-alloy Steel Tubes and | 26.9-2743mm |

Fittings for the Conveyance of | |||

Water and Other Aqueous | |||

Liquids | |||

EN 10297-1 | E235,E275,E315,E355,E470, | Seamless Circular Steel Tubes | 26.9-610mm |

E275K2,E355K2,E420J2,E460K2, | for Mechanical mid General | ||

E590K2,F730K2 C22E,C35E,C45E,C60E, | Engineering Purposes-1: | ||

38Mn6,41Cr4,25CrMo4,30CrMo4, | Non-alloy and Alloy | ||

34CrMo4,42CrMo4,36CrNiMo4, | Steel Tubes | ||

30CrNiMo8,4lNiCrMo7-3-2 | |||

EN 10305-1 | E215,E235,E355 | Steel Tubes For Precision | 4-260mm |

Applications-1: | |||

Seamless Cold Drawn Tubes | |||

EN 10305-4 | E215,E235,E355 | Steel Tubes for precision | 4-80mm |

Applications-4: | |||

Seamless Cold Drawn Tubes | |||

for Hydraulic mid Pneumatic | |||

Power Systems |

- Q:What do you mean by "SC" in welded pipe SC200? What's the diameter of 200?

- Including galvanized steel pipe, but galvanized steel pipe is generally used for plumbing professional, electrical professional generally only civil air defense or high anti-corrosion requirements of the region;

- Q:Can steel pipes be used for bridge construction?

- Yes, steel pipes can be used for bridge construction. Steel pipes are often used in the construction of bridges due to their high strength, durability, and ability to withstand heavy loads and harsh weather conditions. They can be used for various components of a bridge, including piers, supports, and even the bridge deck itself. Steel pipes are preferred in bridge construction as they provide excellent structural integrity and can be easily fabricated and installed.

- Q:What are the factors that affect the pressure rating of steel pipes?

- There are several factors that can affect the pressure rating of steel pipes. 1. Material strength: The strength of the steel used in the pipe construction plays a crucial role in determining its pressure rating. Higher strength steel can withstand higher pressure levels, whereas weaker grades of steel may have lower pressure ratings. 2. Wall thickness: The thickness of the pipe wall directly impacts its pressure rating. Thicker walls can handle higher pressure levels as they provide more resistance against the internal forces exerted by the fluid or gas flowing through the pipe. 3. Pipe diameter: The diameter of the steel pipe also influences its pressure rating. Generally, larger pipes have higher pressure ratings as they have a larger cross-sectional area to distribute the internal pressure forces. 4. Temperature: Elevated temperatures can significantly affect the pressure rating of steel pipes. High temperatures can weaken the steel material, reducing its overall strength and, consequently, its pressure rating. Therefore, it is important to consider the maximum operating temperature when determining the pressure rating of steel pipes. 5. Corrosion resistance: Corrosion can weaken the pipe material over time, leading to a decrease in its pressure rating. Various factors such as the type of fluid being transported, pH levels, and environmental conditions can impact the corrosion resistance of steel pipes. Utilizing corrosion-resistant coatings or selecting stainless steel pipes can help mitigate this factor. 6. Manufacturing standards: Compliance with recognized industry standards and specifications is crucial in determining the pressure rating of steel pipes. These standards ensure that the pipes are manufactured using proper techniques and materials, providing reliable and accurate pressure ratings. 7. External loads: External loads or forces acting on the pipes, such as soil settlement, traffic loads, or installation practices, can affect their pressure rating. Proper design and installation techniques, including adequate support and protection, are essential in ensuring the pipes can withstand these external forces without compromising their pressure rating. It is important to consider all these factors and consult relevant industry standards and guidelines to determine the appropriate pressure rating for steel pipes in different applications.

- Q:Difference between seamless steel pipe and welded pipe

- Welded steel pipe for different welding process and divided into the furnace pipe welding (ERW) pipe and automatic arc welding, because of the different forms of welding seam welded pipe and spiral welded pipe is divided into two kinds, end its shape is divided into circular welded and shaped (square) pipe etc..

- Q:Are steel pipes resistant to chemicals?

- Yes, steel pipes are generally resistant to chemicals. However, their resistance may vary depending on the specific type of chemical and the grade of steel used. Some chemicals may cause corrosion or degradation of the steel over time, so it is important to consider the compatibility of the pipe material with the intended chemicals before use.

- Q:What are the different types of steel pipe coatings for underground gas pipelines?

- There are several types of steel pipe coatings used for underground gas pipelines, including fusion bonded epoxy (FBE) coating, three-layer polyethylene (3LPE) coating, and three-layer polypropylene (3LPP) coating. These coatings provide protection against corrosion, abrasion, and other external factors, ensuring the longevity and safety of the gas pipelines.

- Q:How do you calculate the pipe volume flow rate for steel pipes?

- The pipe volume flow rate for steel pipes can be calculated using the formula: V = A * V_avg, where V is the volume flow rate, A is the cross-sectional area of the pipe, and V_avg is the average velocity of the fluid flowing through the pipe.

- Q:Can steel pipes be used for conveying corrosive substances?

- No, steel pipes are not recommended for conveying corrosive substances as they are prone to corrosion themselves.

- Q:How do steel pipes handle high-pressure applications?

- Steel pipes are commonly used in high-pressure applications because of their inherent strength and durability. The high tensile strength of steel allows it to withstand the pressure exerted on the pipes without deforming or bursting. Moreover, steel pipes are resistant to corrosion, making them ideal for handling various types of fluids and gases under high-pressure conditions. Additionally, the seamless construction of steel pipes eliminates weak points and ensures their reliability and safety in high-pressure environments.

- Q:How are steel pipes used in bridge construction?

- Steel pipes are commonly used in bridge construction as piling or foundation elements. They are driven into the ground to provide support and stability to the bridge structure. Additionally, steel pipes can be used as structural members in the bridge's superstructure, such as for the construction of bridge piers or trusses, due to their high strength and durability.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

ASTM A 106 GRB cold drawn seamless steel pipe

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords