ASTM 316L Embossing Stainless Steel Sheet / Stainless Steel Sheet Embossed

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

ASTM 316L Embossing Stainless Steel Sheet / Stainless Steel Sheet Embossed

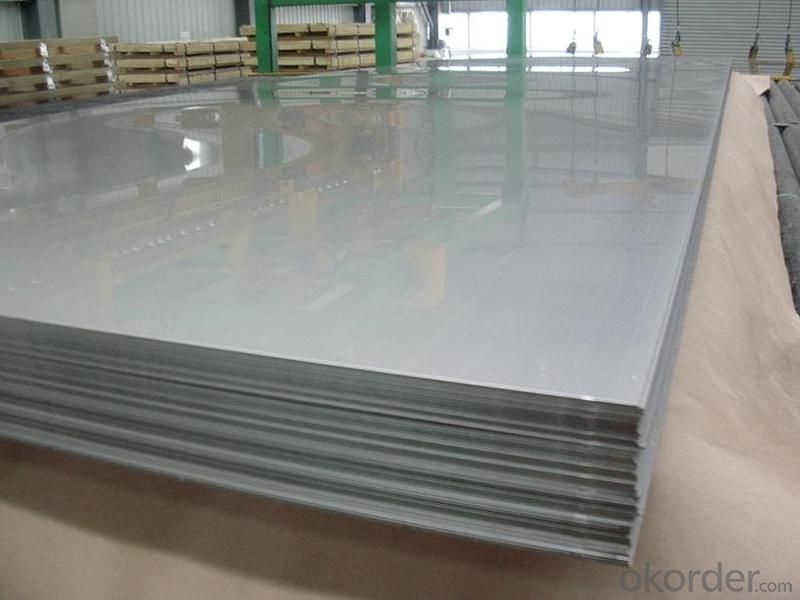

Packaging Details:Wooden pallets,water proof paper-20'GP or 40'GP for stainless steel sheet.

Delivery Detail:within 5-7 days after receiving the deposit

1. Specifications about stainless steel sheet

Commodity | Professional 430 201 202 304 304l 316 316l 321 310s 309s 904l stainless steel sheet |

Grade | 201,202,304,304L,316,316L,310S,309S,321,301,310,410,420,430,904L |

Brand | TISCO ,BAOSTEEL,POSCO,JISCO,LISCO |

Certification | SGS,BV,IQI,TUV,ISO,etc |

Thickness | 0.2mm-150mm |

Width | 1000,1219,1250,1500mm, or as your requirements |

Length | 2000,2438,2500,3000,6000mm, or as your requirements |

Surface | No.1, 2B, BA, 8K Mirror, Hairline,satin, Embossed,brush,No.4,HL,matt,pvc film,laser film. |

Standard | ASTM,AISI,SUS,JIS,EN,DIN,GB, ASME,etc |

Delivery time | 5-7 days after confirming the order |

MOQ | 1 Ton |

Advantages | Showing the splendor of your quality, wearresistant as well , strong corrosion resistance and decorative effect, durable and beautiful in good taste. |

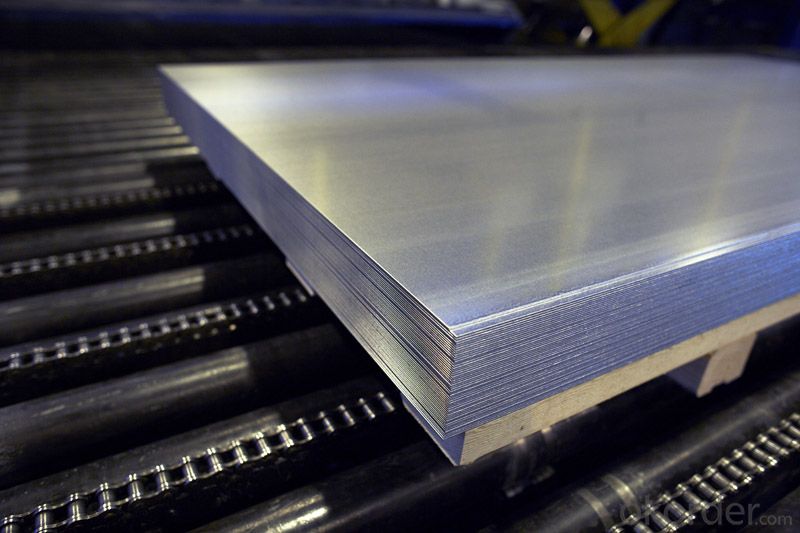

2.Production Flow about stainless steel sheet

Raw materials are sending to hot rolling units for rolling into different sizes

Hot rolled material is annealing in cold; rolled annealing furnace and pickling in acid.

All mill rolls are grinded on precision grinding machine with proper chamfering after first shiftoperation.

All sheets are pickled in different tanks and dried on brush roll machine before dispatched.

These sheets are again annealing and are sent to straighten machine for straightening.

Inspections are done at various stages. Keep proper control overall internal process via rolling,annealin and pickling by our experienced staff.

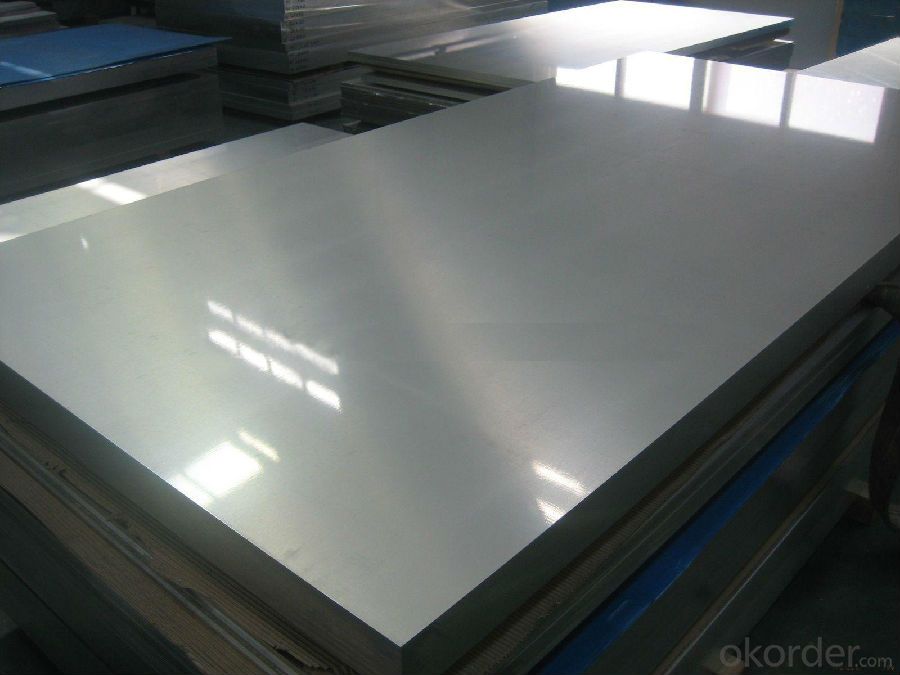

3.Surface--stainless steel sheet

| Surface Finish | Definition | Application |

| 2B | Those finished, after cold rolling, by heat treatment, pickling or other equivalent treatment and lastly by cold rolling to given appropriate luster. | Medical equipment, Food industry, Construction material, Kitchen utensils. |

BA/8K mirror | Those processed with bright heat treatment after cold rolling. | Kitchen utensils, Electric equipment, Building construction. |

| NO.3 | Those finished by polishing with No.100 to No.120 abrasives specified in JIS R6001. | Kitchen utensils, Building construction. |

| NO.4 | Those finished by polishing with No.150 to No.180 abrasives specified in JIS R6001. | Kitchen utensils, Building construction, Medical equipment. |

| Hairline | Those finished polishing so as to give continuous polishing streaks by using abrasive of suitable grain size. | Building Construction. |

| NO.1 | The surface finished by heat treatment and pickling or processes corresponding there to after hot rolling. | Chemical tank, pipe. |

- Q:What are the different types of surface finishes for stainless steel sheets?

- There are several different types of surface finishes for stainless steel sheets, including brushed, mirror, embossed, bead blasted, and satin.

- Q:Are stainless steel sheets resistant to chemicals and acids?

- Yes, stainless steel sheets are resistant to chemicals and acids. Stainless steel contains a high percentage of chromium, which forms a protective layer on the surface of the metal, making it highly resistant to corrosion and damage from chemicals and acids. This corrosion-resistant property is further enhanced by the addition of other elements such as nickel and molybdenum. Stainless steel sheets are widely used in various industries, including chemical processing, pharmaceuticals, food and beverage, and automotive, where they are exposed to aggressive chemicals and acids. The resistance of stainless steel to chemicals and acids makes it a reliable and durable material for applications that require resistance to corrosion and chemical attack.

- Q:Are stainless steel sheets available in different finishes?

- Indeed, there are various finishes in which stainless steel sheets are available. Stainless steel is a highly adaptable substance that can be finished in diverse manners for distinct visual and textural effects. Among the frequently used finishes are brushed, mirror, satin, and textured finishes. Each finish possesses its own distinctive aesthetic charm and can be selected according to the desired appearance and particular application demands. Moreover, the chosen finish can also influence the resistance of the stainless steel sheets against corrosion, staining, and scratching. Consequently, manufacturers provide an array of finishes to accommodate different customer preferences and specific project requirements.

- Q:How are stainless steel sheets measured?

- Stainless steel sheets are typically measured in terms of thickness, width, and length. The thickness is usually expressed in gauge or millimeter, while the width and length are measured in inches or feet.

- Q:Can stainless steel sheets be used for elevator shafts?

- Yes, stainless steel sheets can be used for elevator shafts. Stainless steel is a durable and corrosion-resistant material that is commonly used in construction for its strength and aesthetic appeal. Elevator shafts require materials that can withstand constant use and exposure to various elements, making stainless steel an ideal choice.

- Q:What is the impact resistance of stainless steel sheets?

- Due to its unique properties and composition, stainless steel sheets exhibit a high level of impact resistance. This refers to their ability to withstand sudden loads or forces without suffering permanent deformation or breakage. The material possesses exceptional toughness and durability, rendering it highly resistant to impact. The impact resistance of stainless steel sheets can be attributed to their high tensile strength and ductility. This alloy, which contains iron, chromium, and other elements, contributes to its strength and corrosion resistance. The presence of chromium forms a protective oxide layer on the steel's surface, preventing easy rusting or corrosion. Moreover, stainless steel sheets are available in various grades, each with its own composition and properties. The most commonly utilized grade for impact-resistant applications is 304 stainless steel, which offers good resistance against impact and finds widespread use in industries such as construction, automotive, and aerospace. The impact resistance of stainless steel sheets also depends on their thickness. Thicker sheets tend to possess greater impact resistance due to their increased mass and structural integrity. However, even thinner stainless steel sheets can provide significant impact resistance owing to the inherent strength and toughness of the material. In practical applications, stainless steel sheets are frequently employed in environments where impact resistance is vital, such as in the manufacture of machinery, equipment, and structures subject to high loads or potential impacts. They can endure heavy impacts without cracking, fracturing, or deforming, thereby ensuring the integrity and longevity of the final product. Overall, stainless steel sheets exhibit excellent impact resistance, making them a preferred choice in various industries. Their high strength, corrosion resistance, and durability render them suitable for applications where resistance to impact is crucial.

- Q:What are the different edge finishes available for stainless steel sheets?

- For stainless steel sheets, there are multiple edge finishes available, each with its own distinct characteristics and applications. 1. The mill edge is the original edge produced during the rolling process at the mill. It has a slightly rough appearance and may contain mill scale or imperfections. This edge is suitable for industrial or structural use, where aesthetics are not a primary concern. 2. The sheared edge is obtained by cutting or shearing the stainless steel sheet to size. It has a clean-cut, straight appearance and is commonly used in applications where a smooth edge is desired, such as architectural or decorative purposes. 3. After the shearing process, the edges of the stainless steel sheet can be deburred to remove any sharp or rough edges. This creates a smooth and safe edge, making it suitable for applications where safety is a concern, such as food processing or medical equipment. 4. The rolled edge is achieved by rolling the stainless steel sheet, resulting in a rounded or curved edge. This edge finish is often used in applications where safety is important, as it eliminates sharp corners and edges, reducing the risk of injury. 5. A beveled edge is created by cutting or grinding an angle onto the edge of the stainless steel sheet. This edge finish is commonly used in architectural or decorative applications, as it provides a stylish and visually appealing appearance. 6. The polished edge involves polishing the edge of the stainless steel sheet to create a smooth and reflective surface. Polished edges are often used in high-end architectural or decorative applications, as they enhance the overall aesthetic appeal of the stainless steel sheet. When choosing the appropriate edge finish for your application, it is essential to consider factors such as aesthetics, functionality, and safety.

- Q:Are stainless steel sheets suitable for laser cutting?

- Indeed, laser cutting proves to be a suitable technique for cutting stainless steel sheets. By effortlessly penetrating the material, lasers facilitate the creation of precise and pristine cuts. The elevated heat resistance of stainless steel sheets further renders them ideal for laser cutting, as they endure the intense heat produced by the laser beam. Moreover, owing to their exceptional corrosion resistance, stainless steel sheets enjoy significant popularity across diverse industries. The utilization of laser cutting guarantees minimal distortion and eliminates any physical contact with the material, thereby yielding a finished product of superior quality.

- Q:Are stainless steel sheets resistant to lactic acid?

- Stainless steel sheets are commonly resistant to lactic acid. The corrosion resistance of stainless steel is well-known, and lactic acid is generally not potent enough to cause substantial harm to surfaces made of stainless steel. Nevertheless, the level of resistance may differ based on the specific grade and quality of stainless steel employed. To ensure the suitability of stainless steel sheets for applications involving lactic acid, it is advisable to seek guidance from a material expert or conduct appropriate testing.

- Q:What is the modulus of elasticity of stainless steel sheets?

- The modulus of elasticity, also known as Young's modulus, is a measure of the stiffness or rigidity of a material. For stainless steel sheets, the modulus of elasticity typically ranges from 190 to 200 gigapascals (GPa). However, it is important to note that the modulus of elasticity can vary depending on the specific type and grade of stainless steel, as well as factors such as temperature and strain rate.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

ASTM 316L Embossing Stainless Steel Sheet / Stainless Steel Sheet Embossed

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords