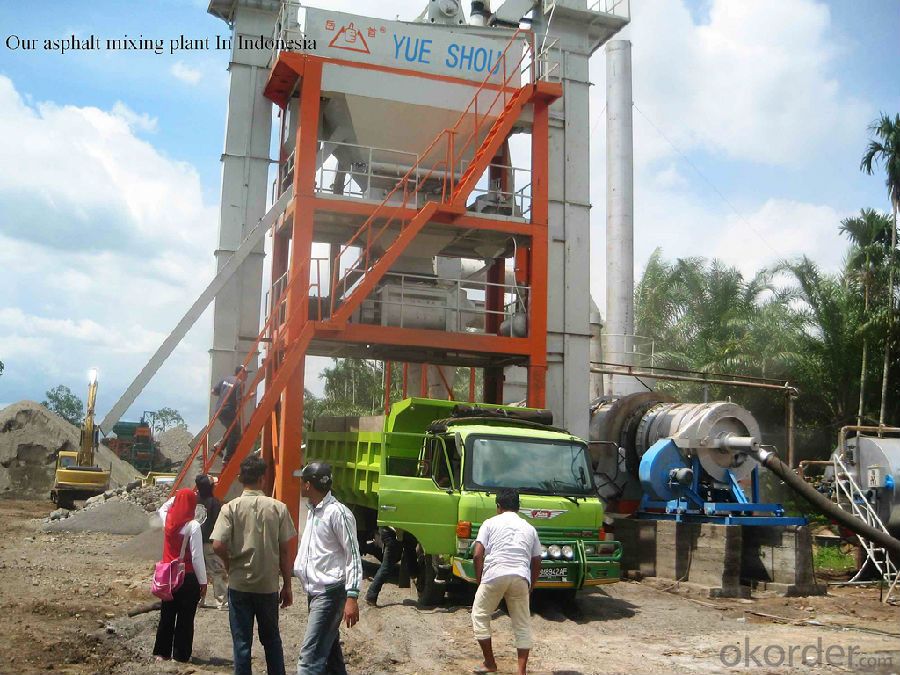

asphalt mixing plant LB800 capacity 64t/h,good reputation in russian,Top 10 in 2014,hot sale LB1500 in russian

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

LB800 Asphalt Mixing Plant with capacity 64t/h

Item | Description | Qty. (set) |

01 | Cold Aggregate Batching Machine and Feeders Group of four components, unit capacity of the aggregate hopper is 5M³ (full hopper), total capacity is 20M³; Adopts imported variable-frequency governor Continuous dosing belt & and driving reduction motor group, group of 4 units; The electric vibrato: 2 units | 1 |

02 | Feeding belt conveyor | 1 |

03 | The Drying Drum Ø1450×6300 MM, rotating speed: 11.3 RPM; Cylinder on frame, Rotation drive through electric motor and reduction box, The heat-preservation is 50mm rack wool and stainless steel | 1 |

04 | EBICO Gas burners Fuel :Natural gas | 1 |

05 | Cyclone dust collector |

|

06 | Bag dust collector |

|

07 | The hot aggregate elevator: capacity 80 T/H | 1 |

08 | The filler bin: 0.6 M³, the capacity of the filler elevator: 25T/H | 1 |

08 | The vibrating screen unit 4 grades, capacity 80T/H | 1 |

09 | The hot aggregate storage bin 4 numbers, the total volume is 10 M³, 4 units level indicator, temperature detector | 1 |

10 | The weighing devices The weighing unit for powder, aggregate and bitumen (each has one unit) | 1 |

11 | The mixing tower The main tower with supporting legs, repairing platform and guardrail | 1 |

12 | The mixer Capacity: 800 KG/batch, the motor power: 30KW | 1 |

13 | Vibration screen |

|

14 | Asphalt supply system and heating system 2 units 25 tons bitumen tank with hot oil heating system |

|

15 | Pneumatic control system | 1 |

16 | Electric control system |

|

17 | Control room |

|

18 | With 30ton bottom-set finished mixture storage tank | 1 |

- Q:What is the special work of the concrete mixing station

- Mixer operator, welder, tester, loader driver's license, assessor

- Q:How much concrete is produced per hour by HZS180 concrete mixer?

- Depending on the different areas of the site, the requirement is between 10 and 300, 000, which requires a high level of testing equipment. The cost is relatively higher. The best way is to find a few different test equipment suppliers, according to different manufacturers, equipment, and make a simple quote analysis

- Q:Which staff does the concrete mixing station need?

- Mainly depends on how big is your station, whether can fully staffed, mainly included: general manager, deputy general manager, technology, webmaster, laboratory (deputy) director of the general, the production manager, sales managers, salespeople, scheduling, lab team leader, the operator (inspection), quality inspection, proportioning design, the material inspector technicians, machine operators, resposible, site, monitor of overhaul, maintenance engineer, loadometer, finance, cashier, mixers, pump truck drivers, company drivers, forklift driver, the handyman, chef, etc These are the main people who want to help you.

- Q:Concrete mixstations belong to no special equipment

- Special equipment is referred for life safety, greater danger of boilers, pressure vessels (including gas cylinders, hereinafter the same), pressure pipes, elevators, lifting machinery, passenger ropeway, large-scale amusement facilities. The boiler, pressure vessel (air bottle), pressure vessel is the pressure type special equipment; Elevator, hoisting machinery, passenger rope and large amusement facilities are special equipment for mechanical and electrical equipment.

- Q:What are the facilities of the concrete mixing station

- It can be divided into five large parts of the mixing host, material weighing system, material conveying system, material storage system and control system

- Q:How to choose a good concrete mixer station?

- Selection is best good survey is supply and demand situation of you and how many mixing station, concrete demand how, don't blindly pursuing big equipment, vehicles and personnel left unused, but it is now generally good, as long as the operation, mixing station not at a loss

- Q:What does HZS mean in the HZS120 concrete mixing station

- Because building aggregate measurement compared with standing aggregate metering, reduced the four of the intermediate links, and the vertical blanking metering, saved measuring time, thus greatly improving the production efficiency, under the condition of the same model, mixing building production efficiency than mixing plant production efficiency by a third. Such as: HLS90 floor of production efficiency and production efficiency of HZS120 stand HLS120 floor of production efficiency, production efficiency is equivalent to HZS180 stand HLS180 floor of the production efficiency is equivalent to the productivity of HZS240 station.

- Q:What is the concrete of the mixing station?

- I am at the work station, the concrete mixing plant is operating goods, use the material such as cement, fly ash, sand, water reducing agent in strict accordance with the provisions of the state standard the ratio of mixing, through concrete truck mixer (commonly known as "car" river) transportation to the construction site, recycled concrete pump for handlebar concrete on the building site. For building products safety, now the big building construction are banned to mix concrete, concrete supply must to the recognition of concrete mixing station to buy, hope to help you.

- Q:What kind of sand do you need for a concrete plant? I don't know where to start!

- This is the premise of the 2.3-2.6 (which is better in this range) It can also be used by means of mechanism sand or mixed sand (coarse sand is used in a certain proportion), depending on the price of raw materials, to save the cost

- Q:How much water does a concrete mixer use every day?

- Water is an indispensable part of the concrete production industry. As an investment company in a concrete mixing station, it is also important to have control over water use. It is also an aspect of production cost control. The use of water used in concrete stations is not the main water link. Flush the blender and cement truck every day to use a lot of water. The concrete is very difficult to handle because of the condensation. So it is the most effluent project in the production standstill. And the washings of these rinsing equipment contain water slurry, aggregates and aggregates, etc. From the environmental point of view, the water of cement mortar or concrete is strong alkaline, the PH value is high, can reach about 12, free discharge can pollute the environment. Therefore, with the continuous improvement of the environmental requirements in recent years, the waste water treatment of the mixing station becomes the main concern.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

asphalt mixing plant LB800 capacity 64t/h,good reputation in russian,Top 10 in 2014,hot sale LB1500 in russian

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords