Asphalt Batching Plant with productivity of 64 t/h

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t

- Supply Capability:

- 1 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

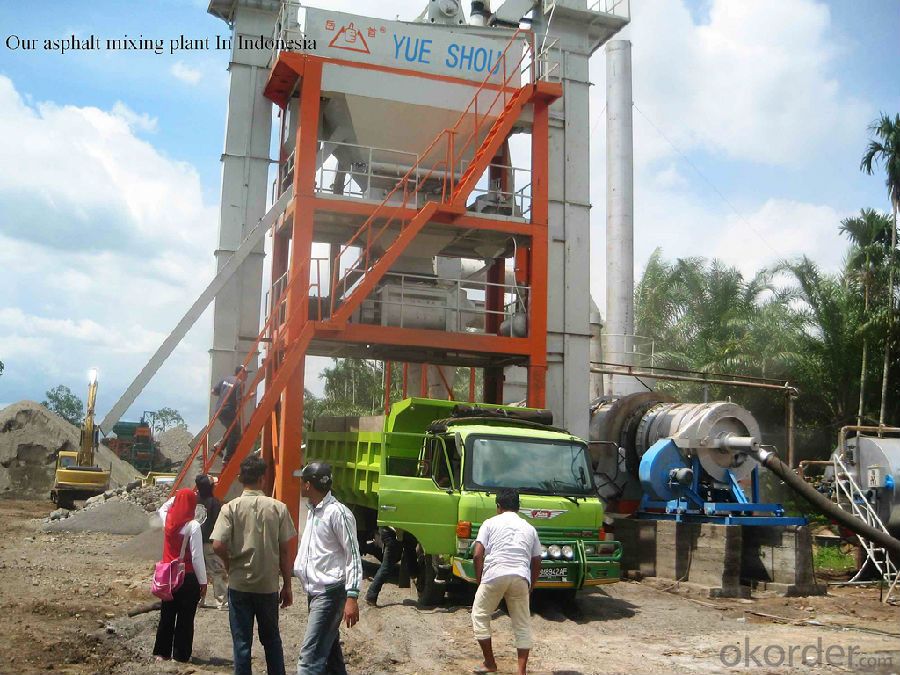

LB800 Asphalt Mixing Plant with capacity 64t/h

Item | Description | Qty. (set) |

01 | Cold Aggregate Batching Machine and Feeders Group of four components, unit capacity of the aggregate hopper is 5M³ (full hopper), total capacity is 20M³; Adopts imported variable-frequency governor Continuous dosing belt & and driving reduction motor group, group of 4 units; The electric vibrato: 2 units | 1 |

02 | Feeding belt conveyor | 1 |

03 | The Drying Drum Ø1450×6300 MM, rotating speed: 11.3 RPM; Cylinder on frame, Rotation drive through electric motor and reduction box, The heat-preservation is 50mm rack wool and stainless steel | 1 |

04 | EBICO Gas burners Fuel :Natural gas | 1 |

05 | Cyclone dust collector |

|

06 | Bag dust collector |

|

07 | The hot aggregate elevator: capacity 80 T/H | 1 |

08 | The filler bin: 0.6 M³, the capacity of the filler elevator: 25T/H | 1 |

08 | The vibrating screen unit 4 grades, capacity 80T/H | 1 |

09 | The hot aggregate storage bin 4 numbers, the total volume is 10 M³, 4 units level indicator, temperature detector | 1 |

10 | The weighing devices The weighing unit for powder, aggregate and bitumen (each has one unit) | 1 |

11 | The mixing tower The main tower with supporting legs, repairing platform and guardrail | 1 |

12 | The mixer Capacity: 800 KG/batch, the motor power: 30KW | 1 |

13 | Vibration screen |

|

14 | Asphalt supply system and heating system 2 units 25 tons bitumen tank with hot oil heating system |

|

15 | Pneumatic control system | 1 |

16 | Electric control system |

|

17 | Control room |

|

18 | With 30ton bottom-set finished mixture storage tank | 1 |

- Q:What is the daily routine of the concrete mixing station?

- Your question is fun, you ask is daily work refers to a person or the institution will have job or responsibility, and concrete mixing plant is short for a single search or mixing unit, I put the question to you "what's the concrete mixing station management personnel daily work including".

- Q:How much concrete is produced by the js1000 type of the concrete mixing station

- The JS1000 is only the mainframe model and depends on the power of the whole machine and the size of the batching machine. The JS1000 has HZS50, 60, 75, which is in theory, 50, 60 and 75 per hour. The actual operation is certainly less, about 80%

- Q:What raw materials and equipment do you need for your own admixture?

- The main ingredients of admixtures are: the mother fluid, the composition of the air and the composition of the mixture, and the water. The concrete formulations are determined according to the different materials of concrete, which is usually the mother solution and the adjustment time. The parent fluid is itself well adapted and does not require a lot of material. Complex admixtures do not require any other equipment except for the geosyncline configuration.

- Q:The main components of a mixing station

- The concrete mixing station consists mainly of five major systems, such as mixing main, material conveying system, material weighing system, material storage system and control system.

- Q:Classification of concrete mixing stations

- There is the distinction between level 1, level 2, level 3. Because some projects, especially the project of the state, are required to provide the units of concrete, and the quality is low because of the low quality. There is a clear list of bids in general.

- Q:How long does it take to build a concrete mixer station?

- The main idea is that the goods are completely incomplete, and the crane, the manpower, the mechanical tools. If everything is in place, then the pure installation will be two weeks to a month. Of course, also see you buy what type of product, container type is compared commonly faster, smaller and faster, under 3000 type slightly faster, 4000 and 5000 slowly

- Q:How to choose a good concrete mixer station?

- The concrete mixing station of choose and buy should focus on quality and quantity. Some users choose and buy when the concrete mixing station, don't know how should choose the equipment, now there are goods on the market of concrete mixing station, concrete mixing station, concrete mixing station. Users should choose different devices and different type of concrete mixing stations according to their own situation.

- Q:How much water does a concrete mixer use every day?

- Dosage, depending on your project and mixing station construction factory cleaning every day, because now the country's love the strict monitoring of environmental protection, to maintain clean our factory, is a lot of water to clean the work area. So the client had better prepare the pool to ensure the normal operation of the project.

- Q:The average commodity concrete is mixed with a day to use how much fly ash

- That depends on the amount of concrete and the ratio, there is no absolute value. In concrete, the amount of cement is very large, and the price of cement per kilogram of cement is more expensive than the price of ash, gravel, sand and water. On the premise of guarantee the quality of concrete, concrete mixing station of utmost reduce the dosage of cement is to reduce unit cost of concrete price, search is one of the important measures to prevent concrete cracking.

- Q:The mixing time of the concrete mixer is in which standard

- Concrete quality control standard gb50164-2011

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Asphalt Batching Plant with productivity of 64 t/h

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t

- Supply Capability:

- 1 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords