Anti-yellowing High Tensile High Clear Polyurethane Plastic TPU Film For Making Raincoat

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Introduction of TPU Film

Compared with the PU film, this kind of TPU film is with:Better elasticity, waterproofing, wear resistance, tear resistance and anti-yellowing.High temperature resistance and cold resistance.

Good for outdoor usage.High resistance to oils, grease and solvents.Good resistance to weather exposure.

2.Application of TPU Film

Household: shower curtain, table cloth, raincoat, umbrella

Bags: cosmetic bags, ziplock bag, cooler bags(liners)

Stationery: book cover, card holders/jackets, binders

3.Advantage of TPU Film

lightweight——low density 0.928 g/cm3

Durability——due to it’s good flexing and cold resistance

Good toughness

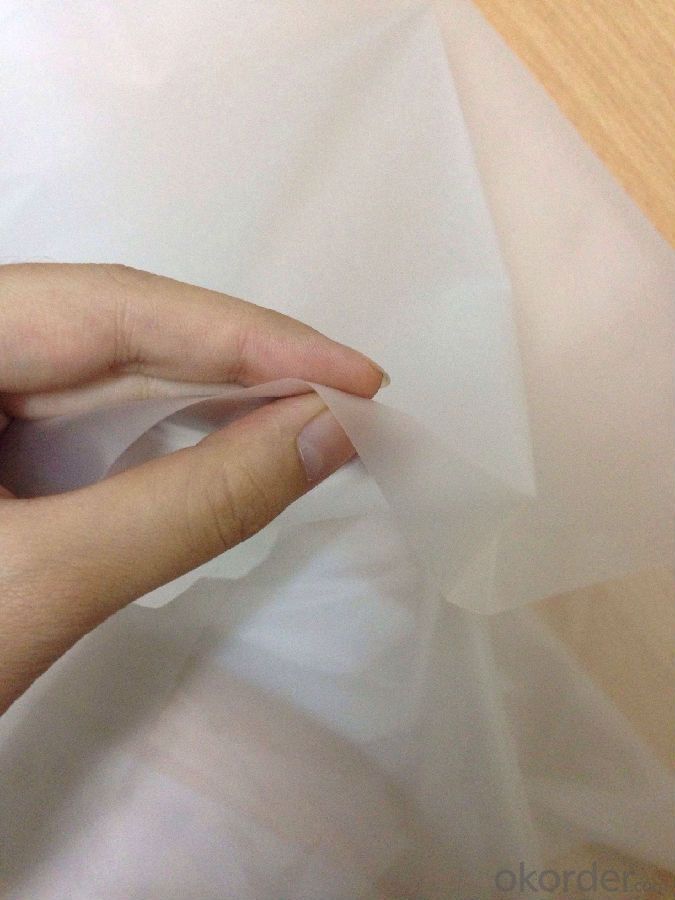

easy edge-tear processing, soft hand feeling

Available for silk screen and offset printing

Non-toxic and without plasticizer, can reach the standard like: FDA, REACH,ROHS,EN71-3

The similar price VS PVC, but more eco-friendly

4.Packing of TPU Film

CNBM TPU film is packed by Seaworthy Packing

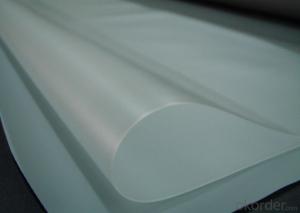

5.Pictures of TPU Film

6.Specification of TPU Film

Item Name | Transparent TPU film |

Full Name | Thermoplastic Polyurethanes |

Material | TPU Granule |

Thickness | 0.05-2.0mm ranged, special requirements can be accept |

Hardness | 75A-95A usually used |

Property | Eco-Friendly, Waterproof, Breathable, Non-Yellow |

Sample | Our stock sample free for you If customize sample need, the sample time is 4-6days |

Package | In roll or carton |

Lead time | 5-10days after sample confirmed, the exactly leadtime according to the QTY |

Payment terms | 30%TT, L/C, Western Union |

Advantage | TPU material is without any air pollution when burned. moreover,they can be decomposed by microorganism within 3-5 years when buried. TPU is the material which is ECO-friendly, high wear and tear resistance, excellent bending resistance, high strength, easy for vacuum forming and printing, easy for high frequency welding, water proof and breathable etc. TPU mateiral has passed the standard of SGS, CE, REACH, ASTM, ISO9001 |

7.Remarks

Our TPU products have passed the inspection of many international well-known tests such as SGS, ASTM, JIS, FDA and so on. Our TPU products are environmental friendly, non-toxic, water resistant, anti-yellowing, hydrolysis resistant, cold tolerant, high temperature resistant and good tearing resistant. Our TPU materials are not only applicable to the modern production field of articles for daily use, but also suitable for military - industrial complex, medical, electronics and other production areas such as for cricket bat, clothing, shoes, medicines, national defense, electronics, packaging materials, Inflatable products, waterproofing material, stone chip protection, high-end building sticker, solar protection film and so on.

8.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

- Q:Is there any way to clean the protective film on standard door?

- The ways to remove the protective film on stainless steel door: 1. If the film is not too big, you can apply some lacquer thinner to it and then scrub it with cleaning ball. 2. Detergent used in textile industry will work (Bottled such detergent is called al). I've tried it. It really works well. 3. Use sulfuric acid. But you should mix it with water before use, otherwise the door will corrode. Immerge the door into the mixed sulfuric acid for a period of time and scrub it with cleaning ball. 4. Firstly, use electric hair drier to heat the film. And them slowly tear it off or scratch it off with wooden shovel. The glue marks can be cleaned by solvent oil. If you don't have hair drier, boiling water is also okay! The best way is to heat the film at first and then clean it with talcum powder. It can stay glossy and new.

- Q:How to get rid of the aging protective film on kitchen ventilator? ?

- If it doesn't affect the appearance too much, you'd better keep it. It may damage the surface coating of the kitchen ventilator or even cause corrosion if you tear it off. If you must remove it, do it in a gentle manner. Ways like heating with fire, scraping with knife or grinding should be chosen with caution because even if it's the glass, scratches may remain on it. You could try to use some oil to soak it but it takes time.

- Q:How to easily tear off the protective film on household appliance that is used for too long?

- Cover the film with warm towel for a while. It will be easy to tear it off.

- Q:How to remove the protective films on floor tiles?

- The anti-fouling film on ceramic tile is actually a layer of protective wax, which can be easily wipe off with damp cloth.

- Q:PE film: the differences between protective film, stretch film and composite membrane.

- There are many kinds of materials used in protective films, such PE, PET and OPP. The film is mainly used during prodution of products and delivery of finished products. Stretch film is a kind of film with thinness and high tensile strength made from PE materials.And it's mainly used on packaging. For example, logistics companies, transport companies and express companies use it to pack products.And composite flim is composited with several different materials, like PE and PET. This type of film is more high-temperature resistant than ordinary PE protective film.

- Q:What are the main ingredients of the PE protective film? Is there any harm to human health?

- The main ingredients of PE protective film are PE film and acrylic adhesive, which are made into protective film,

- Q:How about the electrostatic adsorptive function of PE protective film ?

- 1. Corona treatment is used in the process of the making of PE protective film, increasing the surface area of the film and making it static to meet the need of the following gluing. It's conducive to the combination of glue and film this way. 2. There's no such PE anti-static protective film with glue itself has adsorption function. Multi-layer film blowing machine can make such product at one time.

- Q:What are the thickness of PET protective films?

- Pet protective film thickness is 0.05mm, 0.08mm, 0.12mm, 0.15mm,PET protective membrane of Baidu has many, like 8 silk, 12.5 silk, and so on.

- Q:Stainless steel plastic film for more than a year, how to remove clean? There is also a layer of plastic film after tearing off how to remove?

- The newly bought stainless steel pots or glass stick on some labels, off the labels, stickers on the traces of it is difficult to remove, wipe with a damp cloth, scraping knife will often leave traces, after repeated practice, I summarized some tips to share with you.On the hard surface of the self-adhesive mark, we can use non greasy wash water on the surface of the object, and then gently wipe with soft cloth; with industrial alcohol or gasoline can also remove these traces. If these stickers are found on the skin, they can also be removed with lemon juice.

- Q:How to remove the protective film on stainless steel?

- Not to tear it down. Peel it off after it's heated by air heater and then wipe the surface of the stainless steel with a warm towel.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Anti-yellowing High Tensile High Clear Polyurethane Plastic TPU Film For Making Raincoat

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords