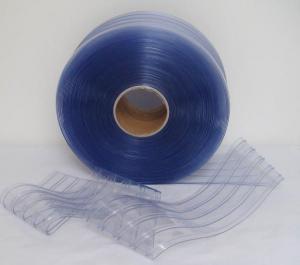

Anti Static PVC Strip Curtains in Green Color

- Loading Port:

- TianJin

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 50 Rolls roll

- Supply Capability:

- 15 Containers Per Month roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of Factory-sale Anti-static PVC Strip Curtains

Application tempt range: -15℃to 50℃

Thickness range from 1.5mm to 6mm

Width range from 150mm to 400mm

Standard Sizes

2mmX200mmX50m; 2mmX300mmX50m;

3mmX200mmX50m; 3mmX300mmX50m;3mmX400mmX50m

4mmX300mmX50m; 4mmX400mmX50m

Applications of Factory-sale Anti-static PVC Strip Curtains

Widely used in electronics, food, pharmaceutical, refrigeration industry.

Can be used as barrier wall,protective portiere/curtain for sensitive area or protective cover for sensitive industry.

Package& Delivery of Factory-sale Anti-static PVC Strip Curtains

Wooden pallet,shirnk film according to custom requires.

Colors of Factory-sale Anti-static PVC Strip Curtains

Green,Clear.

Data sheet of Factory-sale Anti-static PVC Strip Curtains

Performance Text | Standard Clear Formula | Cold Formula | Super Polar Curtain | Unit |

Softness A Hardness | 75+-5 | 65+-5 | 65+-5 | / |

Brittle Point | Approx -35 | Approx -45 | Approx -45 | Degress C |

Falling Ball Test | -20 No Break | -40 No Break | -50 No Break | Degress C |

Flexibility | -20 No Break | -40 Bo Break | -50 No Break | Degress C |

Water Absorption | 0.20% | 0.20% | 0.20% | % |

Tensile Stress | 340 | 420 | 420 | % |

Rupture Resistance | >5 | >2 | >2 | N/mm |

Reaction to fire | Self-Extinguishing | Self-Extinguishing | Self-Extinguishing | 0 |

Flammability | Inflammable | Inflammable | Inflammable | 0 |

Airborne Insulation | ~35dB | ~35dB | ~35dB | 0 |

Light Transmission | >80 | >80 | >80 |

- Q:What are the advantages of using plastic in small kitchen appliances?

- There are several advantages of using plastic in small kitchen appliances. Firstly, plastic is lightweight, making the appliances easy to handle and move around the kitchen. Secondly, plastic is durable and resistant to breakage, ensuring the longevity of the appliance. Additionally, plastic is a good insulator, preventing heat transfer and keeping the exterior cool to touch. Lastly, plastic is cost-effective, allowing for affordable pricing of small kitchen appliances.

- Q:Can home appliance plastics be made from biodegradable materials?

- Yes, home appliance plastics can be made from biodegradable materials. Biodegradable plastics are derived from renewable sources such as plant starch, corn, or vegetable oil. These materials break down naturally over time, reducing the environmental impact compared to traditional plastics.

- Q:How does the use of plastic in home appliances impact the overall lifespan of the appliance?

- The use of plastic in home appliances can have both positive and negative impacts on the overall lifespan of the appliance. On one hand, plastic can make appliances lighter and more affordable, increasing their accessibility to a wider range of consumers. However, plastic is generally less durable than other materials, such as metal, and may be more prone to wear and tear over time. Additionally, certain types of plastic can be susceptible to heat damage or degradation, potentially reducing the lifespan of the appliance. Therefore, while plastic can be beneficial in terms of cost and accessibility, it may also contribute to a shorter overall lifespan for the appliance.

- Q:How do plastic home appliances compare in terms of fire resistance?

- Plastic home appliances can vary in terms of fire resistance, depending on the type and quality of plastic used. Some plastic materials are specifically designed to be fire-resistant and can withstand higher temperatures without igniting or melting. However, not all plastic appliances possess the same level of fire resistance. It's important to consider the specific specifications and safety features of each appliance to determine its fire resistance capabilities.

- Q:How does plastic impact the overall noise reduction properties of home appliances?

- Plastic can significantly impact the overall noise reduction properties of home appliances. It is a lightweight material that can absorb and dampen vibrations, resulting in reduced noise levels. Plastic components, such as housing and insulation, are often used in appliances to minimize noise generated by internal mechanisms. Additionally, plastic enclosures can act as barriers, preventing sound from escaping the appliance and further enhancing noise reduction.

- Q:Can plastic home appliances be used in commercial settings?

- Yes, plastic home appliances can be used in commercial settings. However, their suitability and durability may vary depending on the specific appliance and the demands of the commercial environment. It is important to consider factors such as frequency of use, load capacity, and the potential for wear and tear before using plastic home appliances in commercial settings.

- Q:Do plastic home appliances require any specific cleaning products?

- Yes, plastic home appliances may require specific cleaning products depending on the type of plastic, the appliance's surface, and the type of dirt or stain being cleaned. It's recommended to consult the manufacturer's guidelines or use mild, non-abrasive cleaners to avoid damaging the plastic.

- Q:Are plastic home appliances resistant to mold or mildew?

- No, plastic home appliances are not inherently resistant to mold or mildew.

- Q:Can plastic parts in air conditioners handle the constant exposure to outdoor elements like rain and sunlight?

- Plastic parts in air conditioners are typically designed to withstand outdoor elements like rain and sunlight. They are made from durable materials such as high-quality plastics or polymers that are UV-resistant and water-resistant. However, it is essential to consider the specific brand and model of the air conditioner, as the quality and durability of plastic parts can vary. Additionally, regular maintenance and proper care can significantly prolong the lifespan of these plastic components.

- Q:Are plastic home appliances resistant to electrical surges or power fluctuations?

- No, plastic home appliances are not inherently resistant to electrical surges or power fluctuations. The material used in the construction of the appliance does not provide protection against such events. It is necessary to rely on surge protectors or voltage regulators to safeguard the devices from potential damage caused by electrical surges or power fluctuations.

1. Manufacturer Overview |

|

|---|---|

| Location | Hebei, China |

| Year Established | 1995 |

| Annual Output Value | Above US$ 50 Million |

| Main Markets | 15.00% Mid East 10.00% Northern Europe 10.00% North America 30.00% Eastern Asia 10.00% Africa 9.00% Eastern Europe 8.00% Southeast Asia 3.00% Oceania 3.00% Western Europe 2.00% Southern Europe |

| Company Certifications | ISO 9001 |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Tianjin; Qingdao; Shagnhai; Guanghzou |

| Export Percentage | 41% - 50% |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English; Chinese |

| b)Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | Above 5 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | High; Average |

Send your message to us

Anti Static PVC Strip Curtains in Green Color

- Loading Port:

- TianJin

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 50 Rolls roll

- Supply Capability:

- 15 Containers Per Month roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords