Anti-slip Tape with Solvent Based Acrylic

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 3000000 m²/month

- Option:

- Solvent Tape

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Anti-slip Tape with Solvent Based Acrylic

1. Structure of Anti-slip Tape Description

surface: choice anti-slip sand, rubber anti-slip fiber, sand-free special anti-slip material;

base paper: white/leather silicone paper

middle layer: PET, PP, PVC and aluminum, etc.

base glue: ready-to-use waterproof strong viscose

2. Main Features of Anti-slip Tape

Good impact resistance

Excellent in adhesion

Resistance to cold, heat

Excellent in adhesion and flame retardant

Resistance to age

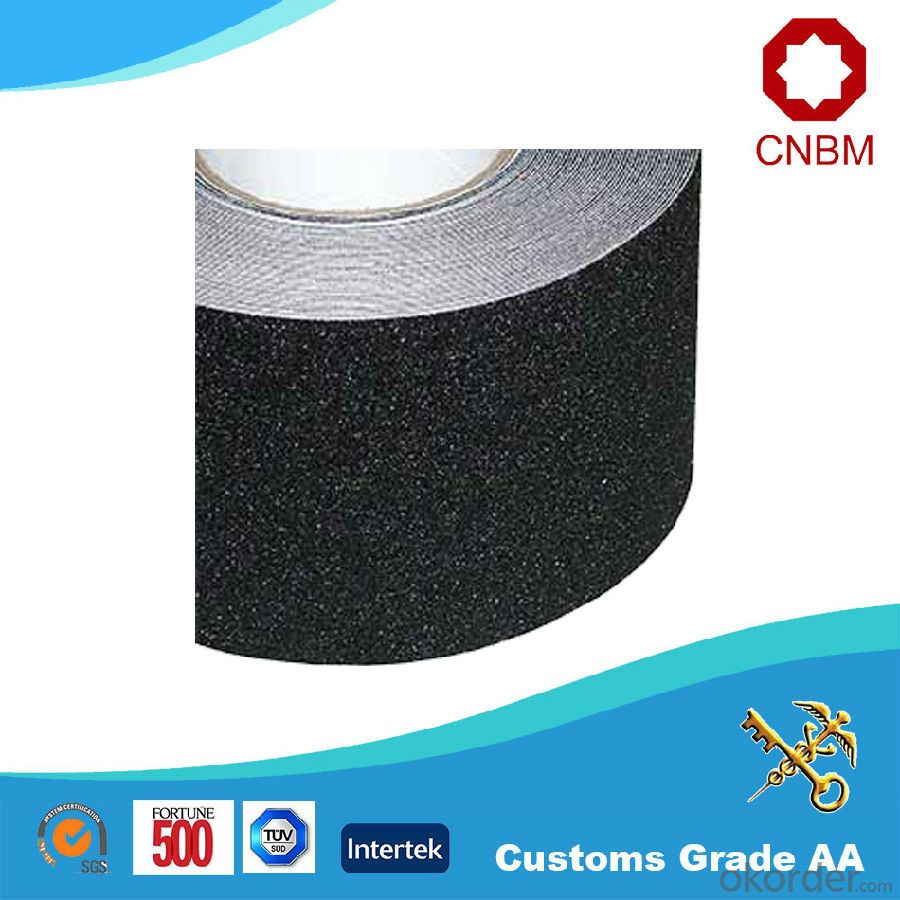

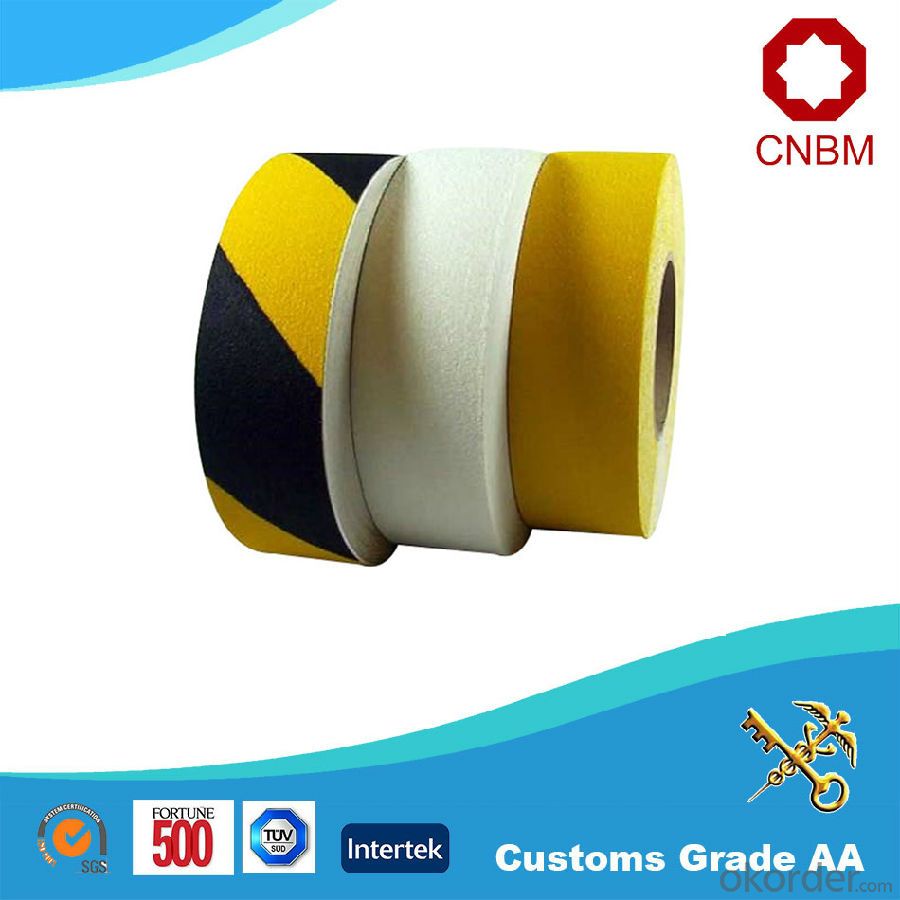

3. Anti-slip Tape Images

4. Anti-slip Tape Description

Item No. | Carrier | Thickness (c) | Anti-skid sand | Surface granularity |

CN-1101 | PVC film | 10 | black corundum | 60 items |

CN-1102 | PVC film | 25 | black corundum | 40 items |

CN-1105 | PVC film | 10 | black corundum | 100 items |

CN-1106 | PET film | 5 | black corundum | 60 items |

CN-1107 | PP film | 5.6 | black corundum | 80 items |

CN-1108 | PET film | 6 | silicon carbide | 50 items |

5. FAQ

Q1. What can we do for you?

Satisfactory sales service

24 hours service for you

Custom-made advices for your need

Your inquiry will be replied within 12 hours.

Professional consultation on your local market

Q2.What are the colors of Anti-slip Tape?

black, gray, red, orange, blue, between yellow and black, red and white, transparent, white, reflective, night light-emitting, etc. printing a variety of beautiful picture and patterns according with customer requirements

Q3. How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

- Q:How do I prevent packaging tape from losing its adhesive properties?

- To prevent packaging tape from losing its adhesive properties, it is important to store it in a cool, dry place away from direct sunlight and extreme temperatures. Additionally, ensure that the surface where the tape is applied is clean and free from any dust, oil, or moisture, as these can compromise the adhesive. Applying the tape firmly and evenly, avoiding excessive stretching, can also help maintain its adhesive strength.

- Q:Can packaging tape be used for sealing plastic food containers?

- Yes, packaging tape can be used for sealing plastic food containers. However, it is important to note that using food-grade adhesive tapes specifically designed for sealing food containers is recommended to ensure safety and maintain the quality of the food.

- Q:Does packaging tape come in different patterns or designs?

- Yes, packaging tape does come in different patterns and designs.

- Q:What are the considerations for using packaging tape on plastic packaging materials?

- When using packaging tape on plastic packaging materials, there are several important considerations to keep in mind. These considerations include: 1. Adhesive Compatibility: It is crucial to ensure that the adhesive used in the packaging tape is compatible with the specific type of plastic material being used. Different plastics have different surface properties and may require different adhesive formulations to ensure proper bonding. For example, low surface energy plastics like polyethylene may require a tape with a specific adhesive designed to adhere to such surfaces. 2. Strength and Durability: Plastic packaging materials come in various thicknesses and strengths. When selecting packaging tape, it is important to consider the strength and durability required for the specific plastic material being used. The tape should be strong enough to securely hold the packaging together without tearing or breaking, ensuring the integrity of the package during handling and transportation. 3. Temperature Resistance: Plastic packaging materials can be sensitive to temperature changes. If the package is exposed to extreme temperatures such as heat or cold, the packaging tape should be able to withstand these conditions without losing its adhesive properties. Certain plastic materials may also shrink or expand due to temperature changes, which can affect the adhesion of the tape. Therefore, it is important to choose a tape that is suitable for the expected temperature range. 4. Residue and Damage: Some packaging tapes may leave behind adhesive residue or cause damage when removed from plastic packaging materials. This can be problematic if the packaging needs to be reused or if the plastic material is sensitive to damage. Selecting a packaging tape that is designed to be easily removable or leaves minimal residue can help mitigate these concerns. 5. Regulatory Compliance: Depending on the industry or product being packaged, there may be specific regulations and standards that need to be followed. It is important to ensure that the packaging tape used complies with any applicable regulations, such as food safety standards or environmental requirements. By considering these factors, one can select the appropriate packaging tape that will effectively adhere to plastic packaging materials while also providing the necessary strength, durability, temperature resistance, and compliance with regulations.

- Q:How does packaging tape perform on fabric or textile surfaces?

- Packaging tape typically does not perform well on fabric or textile surfaces. While it may adhere temporarily, it does not provide a strong bond on these materials and is not designed to withstand the flexibility and movement of fabrics. Additionally, the adhesive on packaging tape may leave residue on the fabric or even damage it when removed. Therefore, it is not recommended to use packaging tape on fabric or textile surfaces. Instead, it is advisable to use specialized fabric tapes or sewing techniques for any applications involving fabrics.

- Q:How do I prevent packaging tape from getting tangled?

- To prevent packaging tape from getting tangled, here are a few tips: 1. Use a dispenser: Invest in a tape dispenser specifically designed for packaging tape. The built-in cutting blade and roller mechanism will help keep the tape controlled and prevent tangling. 2. Start with a clean surface: Before applying the tape, ensure the surface is clean and free from dust, debris, or any other potential obstacles that may cause the tape to stick and tangle. 3. Avoid excessive handling: Minimize handling of the tape as much as possible. Each time you touch the tape, there is a higher chance of it twisting or tangling. Try to handle the tape only when necessary. 4. Cut the tape cleanly: Use a sharp cutter or a dispenser with a cutting blade to make clean and straight cuts. Jagged or uneven cuts can cause the tape to twist or tangle as it is being unrolled or applied. 5. Store it properly: When not in use, store the tape in a cool and dry place, away from direct sunlight or extreme temperatures. Keeping the tape in its original packaging or a designated container can also prevent tangling. 6. Unroll carefully: When unrolling the tape, hold the roll firmly and apply a slight tension to keep it straight. Avoid jerky movements or pulling the tape too forcefully, as this can cause it to twist or tangle. By following these tips, you can minimize the chances of packaging tape getting tangled, making your packaging process smoother and more efficient.

- Q:Can packaging tape be used for sealing plastic containers?

- Yes, packaging tape can be used for sealing plastic containers. Packaging tape is designed to adhere to various surfaces, including plastic, and provides a secure seal to prevent the contents of the container from spilling or getting damaged. It is commonly used for sealing boxes during shipping or storage, but it can also be used effectively on plastic containers. However, it is important to ensure that the tape is firmly applied and that all edges and seams are properly sealed to maintain the integrity of the container.

- Q:Can packaging tape be used for sealing plastic flower pots?

- Indeed, packaging tape is capable of effectively sealing plastic flower pots. This versatile adhesive tape is widely utilized for the purpose of sealing boxes and packages. Its robust adhesive properties render it suitable for securely fastening plastic flower pots, thereby preventing any potential leaks or spills. However, it is crucial to ensure that the surface of the plastic flower pot is devoid of dirt or moisture before applying the tape, as the presence of either could compromise its adhesion. Moreover, it is worth mentioning that there exist specialized tapes explicitly designed for sealing or repairing plastic materials, which may offer superior performance and durability when employed on plastic flower pots.

- Q:What kind of material is used in this kind of tape? What are its features? How are they made? And so on!The more detailed you write, the better!

- Polypropylene is matrix, polypropylene is non-toxic and has no ignition point (but of course it can burn)

- Q:Is packaging tape safe to use on painted surfaces?

- Yes, packaging tape is generally safe to use on painted surfaces. However, it is recommended to test a small, inconspicuous area first to ensure that the tape does not damage or peel off the paint.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Anti-slip Tape with Solvent Based Acrylic

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 3000000 m²/month

- Option:

- Solvent Tape

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords