Anti-Reflective Coated Glass

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 100 m2 m²

- Supply Capability:

- 10000 m2 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

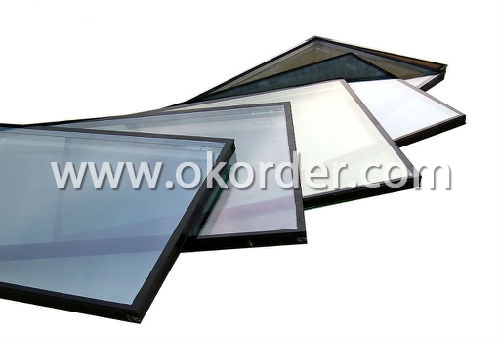

Anti-Reflective Coating Glass, short as AR Glass, is deposited by the hot-dip/immersion plating/dipplating process with anti-reflective coatings on both sides of the glass, making the light transmittance above 98% and reducing largely the reflectivity on the surface of glass compared with the original glass.

Features of Anti-Reflective Coated Glass:

1. Reduce the reflected images, it looks like no glass, greatly enhancing the visual clarity.

2. Make the items true to nature and the colors more beautiful.

3. Further processing (to be tempered, insulated, laminated, etc.) of it is the same as the original glass.

Specifications of Anti-Reflective Coated Glass:

Thickness: 3-12mm (with±0.2mmtolerance)

Max size: 5000*3300mm (with±1mmtolerance)

Applications of Anti-Reflective Coated Glass:

Anti-Reflective Coating Glass is mainly used as flat display panels such as LCD, PDP, outdoor display screen, laptop display and mobile phone display and other electronic display products which need high transmittance and low reflectivity.

AR Glass can also be widely used as building glass, showcase display glass or shopwindow display glass, improving the visual effect significantly.

- Q:What are the raw materials made of glass and plastics?

- Polyethylene (Polyethylene, PE), referred to as PE. is ethylene organic polymer compound. Polyethylene is the best material in contact with food. Non-toxic, tasteless and odorless, conform to the hygiene standards of food packaging. Polyethylene film, transparent, with moisture, oxygen, anti acid and alkali resistance, air tightness in general, excellent heat sealing properties. Known as "plastic flowers" reputation. Plastic packaging and printing volume is the largest and most important materials.PVC-- PVC

- Q:Is it a vacuum cup with fluorine coating that affects the health?

- Fluorine is a nonmetallic chemical element, chemical symbol F, atomic number 9. Fluorine is the halogen elements of a periodic system of A VII family, located in the second period in the periodic table of elements.

- Q:How is glass made? What are the main ingredients?

- Raw material pretreatment. The bulk raw materials (quartz sand, soda ash, limestone, feldspar, etc.) are crushed to damp the raw materials, and the iron bearing raw material is treated with iron to ensure the quality of the glass.

- Q:What's the connection between tempered glass and float glass?

- Tempered glass is made of ordinary glass in the tempering furnace

- Q:How is glass made? What is its raw material?

- Glass is formed by the melting of sand with other chemicals. Glass raw materials for natural ore, the ore will be crushed first, processed into powder, according to the type of glass, according to the formula made of ingredients, into the glass furnace for melting, forming glass liquid. The glass passes through the feed tank and flows out of the feed port to form the stock. The temperature of the stock is 1150~1170 degrees centigrade and the alkali free glass is 1200~1220 degrees centigrade. The material shares every minute near '200 times cut into ball billet. The billet passes through the chute, the ball distributor and the ball plate, and then rolls into different funnels respectively, then falls into a groove formed by three rollers with the same rotating direction. When the ball is rotated on the roller and its surface tension, the ball glass is formed gradually. Its diameter is determined by the thickness, velocity, and shear velocity of the glass stream.

- Q:What material is used in the protective film in the middle of glass?

- Production process is:1: opening, the entire glass will be cut into a larger size than the molding of 0.6mm pieces.2:CNC carved, will open material scrap with steel sand grinding chamfering, drilling (or slot), after the end of CNC on the forming of the carved glass3, flat grinding, mainly to deal with the opening and CNC caused by surface scratches.4: cleaning, ultrasonic cleaning machine will be washed flour, while drying glass.5: tempering, the use of potassium acid to strengthen the glass, so that the stress of glass, strength, resistance and so on to meet certain requirements.6: cleaning: the tempered glass re-entry ultrasonic cleaning.7: stick ab8: packing finished products

- Q:What kind of glass is smoked glass?

- Glass material mainly has three parts: basic material, flux and colorant, and also includes decoloring agent, clarifying agent and corrosion inhibitor

- Q:How can the invisible gauze of screen window increase its pressure resistance (glass fiber material)?

- To have good quality, if the quality of other yarn nets, there may be broken.

- Q:Acrylic plexiglass rod can be used in what way?

- Plexiglass sticks, which cheap plexiglass bonding is an important process, to enhance product quality and taste, affected by two aspects, one is adhesive; two is adhesive skills.

- Q:How to distinguish between good and bad glass fiber reinforced plastic?

- Glass fiber reinforced plastic used for raw materials, resin, glass fiber reinforced plastic fiber silk, filler, calcium powder to 1:1:1 ratio configuration, high-quality glass fiber reinforced plastic choose high-quality resin: unsaturated ortho benzene resin 196, colorless transparent. Low viscosity, low heat release, low shrinkage, high speed cure, high speed compatibility and gloss.

1. Manufacturer Overview |

|

|---|---|

| Location | Guangdong, China |

| Year Established | 1995 |

| Annual Output Value | |

| Main Markets | Mid East; Eastern Europe; Southeast Asia |

| Company Certifications | ISO 9001:2008 |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Shenzhen, China |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | English; Chinese |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | Average |

Send your message to us

Anti-Reflective Coated Glass

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 100 m2 m²

- Supply Capability:

- 10000 m2 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords