Ampoule ISO Standard YBB Standard High Quality

- Supplier:

Triumph Junheng Co.,Ltd

Triumph Junheng Co.,Ltd

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100000 pc

- Supply Capability:

- 1000000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Ampoule ISO Standard YBB Standard High Quality

Neutral borosilicate glass is far superior to low borosilicate glass in terms of hydrolitic resistance, acid and alkali resistance, freezing resistance, filling speed,etc. and it is not easy to cause delamination"due to chemical soaking and corrosion. It is an internationally recognized safe pharmaceutical packaging materials.

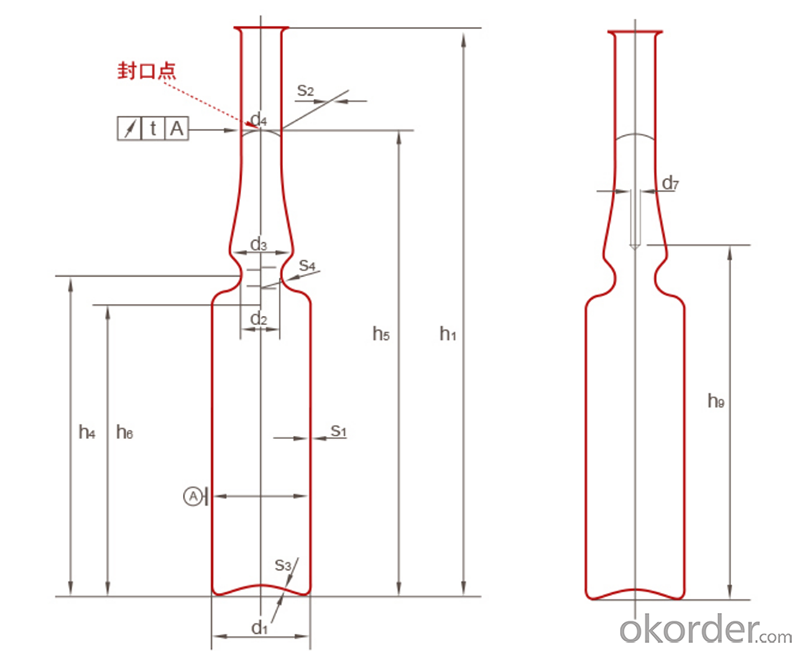

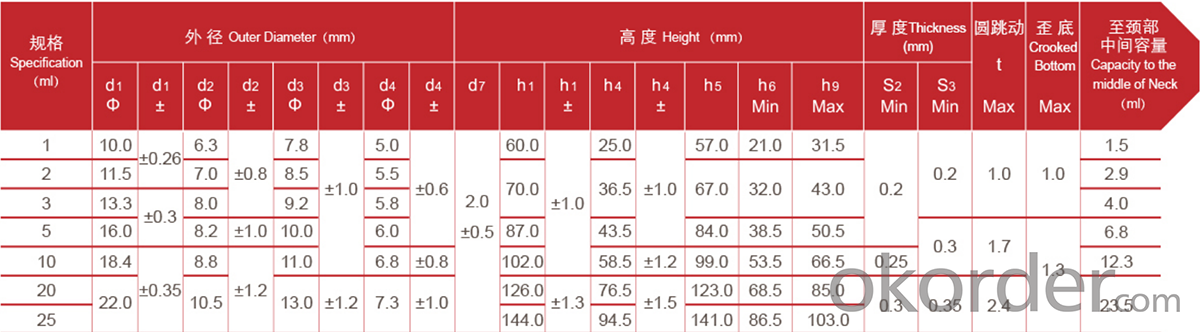

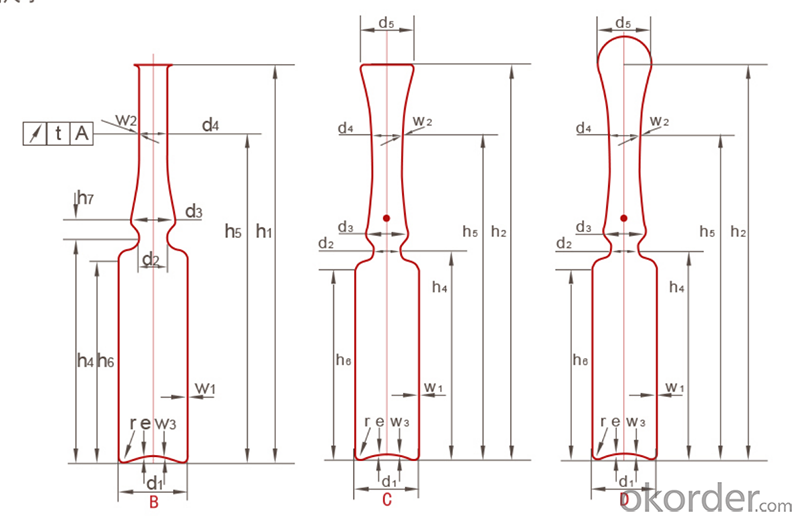

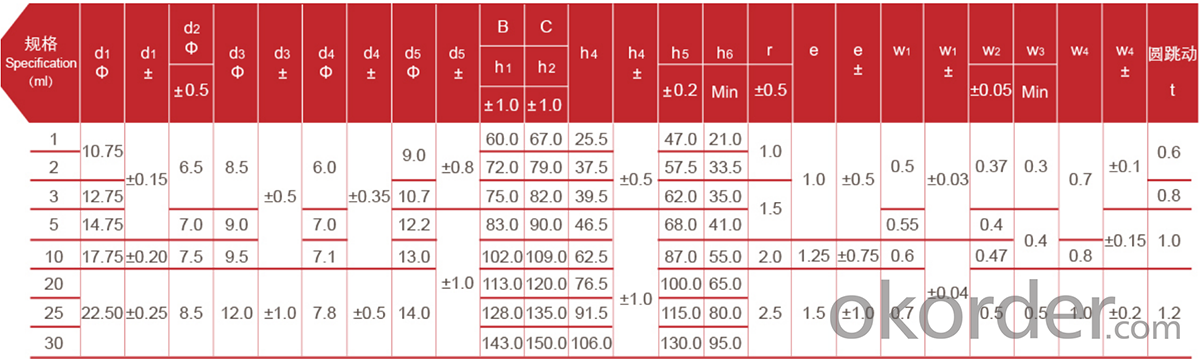

Ampoule YBB Standard

Ampoule ISO Standard

The converting products workshop of the plant has a 100000-level clean room that meets GMP standards, which provides superior production conditions for the production of glass containers and effectively avoids the impact of dust and bacteria on product cleanliness. The inspection system with 7 cameras and 360 continuously rotating and shooting, to detect the glass container body,mouth, shoulder, bottom,inner diameter,edge blind area and mouth bottom edge, as well the dimension, objects inside the container, cosmetic defects (bubbles, impurities and stones).The unqualified products such as crooked container are automatically eliminated, with a detection accuracy of 0.02mm, which ensures that the quality of the glass containers can reach the domestic YBB standard and the international ISO standard. "Excellence Centre"is a project established by Triumph Group and the world leading pharmaceutical packaging material manufacturer-Stevanato Group(Italy). The goal is to introduce world standard tubular glass containers production technology, technical process and quality standards to the Chinese market and make our company's products to keep up with international top standard.

Nationwide Seven Production Bases to Meet the Customers' needTriumph Junheng Co.,(hereinafter referred to as "Triumph Junheng") is a state-owned andprivate mixed ownership enterprise, Triumph Group of CNBM is the controlling shareholder.It ismainly engaged in the research and development, producing and sales of neutral Borosilicateglass tubing(hereinafter referred to as "Neutral Borosilicate glass tubing") and convertingtubular glass products. It has seven production bases located in Handan, Qingdao, Chongqing,Puyang, Anyang, Nanchang and Zhenjiang, which are expected to produce totally 170,000 tons of glass tubing and 136,000 tons of tubular glass container when they are reach full capacity. It is the first high-tech company which realizes stable mass production of high-quality Neutral borosilicate glass tubing with its "oxygen combustion + electric boosting"melting and Danner Tubing drawing technical process in China. It has leading R&D capabilities in the domestic pharmaceutical glass packaging industry, and can provide professional and personalized solutions of pharmaceutical glass packaging materials for materials for tubular glass converting and pharmaceutical companies.

Triumph Junheng builds a comprehensive research and development center for pharmaceutical neutral borosilicate glass in accordance with CNAS certification specifications. Continuously improve the level of laboratory quality management, minimize product quality risks, and meet the requirements of customers and regulations for the authenticity and reliability of testing/calibration to the greatest extent. The R&D center has a team with 30 people, covering various key technical fields such as raw materials analyzing, batching, melting, forming,and post-processing. The center has a building area of 800 square meters and consists of a precision instrument room, a physics laboratory, a chemical laboratory, a balance room, and a high temperature laboratory., Reagent room, equipped with 30 sets(sets)of R&D equipment such as atomic absorption spectrometer, expansion coefficient meter, and electron microscope. The R&D

center focuses on new technologies, intelligence, low energy consumption, localization and standardization, and actively undertakes national and local R&D projects to continuously achieve new technological breakthroughs.

Companys proucts have passed the Qulity inspection and Testing conducted by the national authoritative inspection agencies: Beijing Pharmaceutical Packaging Materials Inspection Institute and International Third Party Testing Agency-SGS. The product quality is fully in line with EP (European Pharmacopoeia), USP United States Pharmacopoeia),JP (Japanese Pharmacopoeia),According to the standard requirements of ISO12775 and the standard of "Neutral Borosilicate Glass Tubing" with Code YBB0012005-2-2015 approved by The National Food and Drug Administration. The expansion coefficient, boron content and hydrolitic resistance of products all have reached the international advanced level.

Quality Inspection

The international advanced automatic online inspection system has been adopted in the production line, which can automatically eliminate unqualified products with defects of dimension and cosmetic and unaligned ends treatment.

Automatic Packaging System

The automatic packaging system can complete the work of heat-shrinking into bundles and stacking into trays, effectively avoiding cosmetic defects such as scratches and impacting caused

by manual operation, ensuring the fastening of each bundle of products and the neatness of each tray.

- Q:Tempered glass and ordinary glass raw materials the same, but the manufacturing method is different, why first heating in rapid cooling, the difference is so great?

- When the glass is heated to a suitable temperature, it cools rapidly, causing a sharp contraction of the glass surface and a compressive stress, while the cooling in the middle of the glass is slower and it is too late to shrink, thus forming a tensile stress and making the glass obtain a higher strength. Generally speaking, the higher the cooling intensity, the greater the strength of the glass.

- Q:How to seal the glass fiber reinforced plastic mould?

- Step up. Concave convex surface or Z face.

- Q:What are the paper made of? What is the glass made of? What is the plastic made of?

- Basically, paper is made from vegetable fiber.

- Q:What kind of glass is alkali free high borosilicate?

- With low density, high chemical durability, and excellent thermal stability, it also has the surface clean, widely used in TFT-LCD LCD glass substrate, excellent flatness characteristics of up to 92% of the visible light transmittance, and excellent alkali precipitation, widely used in optical coating industry, semiconductor industry.

- Q:What is the raw material of glass? How is it converted to glass?

- Melting, the raw materials will be prepared by high temperature heating, forming a homogeneous bubble free liquid glass. This is a complex process of physics and chemistry. The melting of glass is carried out in a furnace. There are two main types of Furnaces: one is a crucible kiln, the other is glass in the crucible, and the other is heated outside the crucible. The small crucible kiln has only one crucible, and the larger one can be more than 20 crucibles. The crucible kiln is made by gap type, and now only optical glass and color glass are produced by crucible kiln. The other is the tank furnace. The frit is molten in the bath, and the flame is heated on the upper part of the glass. The glass melting temperature mostly in the 1300~1600 C Eve joy. Most of them are heated by flame and a few are heated by electric current. They are called electric furnaces. Now, the pool kiln is continuous production, small pool kiln can be a few meters, big can be more than 400 meters

- Q:What is the difference between acrylic board, lotus board, organic board and PVC board?

- Acrylic board is a kind of chemical material. Chemistry called "PMMA" is a polyacrylate, commonly known as "after the special treatment of plexiglass", in the application industry, acrylic raw materials in general in the form of particles, plates, pipes and other forms. Organic glass acrylic and special processing, organic glass products, light boxes with acrylic production has good transparence, pure color, rich colors, beautiful smooth, both day and night of two kinds of effect, long service life, does not affect the use of other features, in addition, acrylic and aluminum plate material, advanced screen printing etc. can be the perfect combination, to meet the business needs of acrylic plastic is to improve the store level business, unified enterprise image of the best form of outdoor advertising.

- Q:What are the materials for car windshields? Is there anything different than ordinary glass?

- Area of toughened glass is a new type of toughened glass, it through special treatment, can impact rupture, crack the glass can still maintain a certain clarity, ensure the driver's field of vision is not affected, has been widely used in the front windshield of the car, but with the demand for vehicle safety and the car environment continues to improve, with the safety performance of laminated glass with good heat insulation and sound insulation performance has gradually become the mainstream of the front windshield.

- Q:Acrylic plexiglass rod can be used in what way?

- Plexiglass sticks, which cheap plexiglass bonding is an important process, to enhance product quality and taste, affected by two aspects, one is adhesive; two is adhesive skills.

- Q:What kind of material is the glass made of?

- The glass is made of glass and the glass is made of silicon dioxide.

- Q:The use of quartz sand

- Derived from various magmatic rocks, sedimentary rocks and metamorphic rocks, less heavy minerals, associated minerals are feldspar, mica and clay minerals. There are two kinds of sedimentary rock genesis and metamorphic origin, the former is not obvious between clastic particles and cement, and the latter refers to quartz rocks with deep metamorphic and pure quality. The quartz veins are formed by hydrothermal action, almost all of them are composed of quartz, and they are compact and massive structures.The mineral content of quartz sand varies greatly, mainly quartz, followed by feldspar, mica, cuttings, heavy minerals and clay minerals.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Ampoule ISO Standard YBB Standard High Quality

- Supplier:

Triumph Junheng Co.,Ltd

Triumph Junheng Co.,Ltd

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100000 pc

- Supply Capability:

- 1000000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products