Amino Trimethylene Phosphonic Acid China Supplier

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 6000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

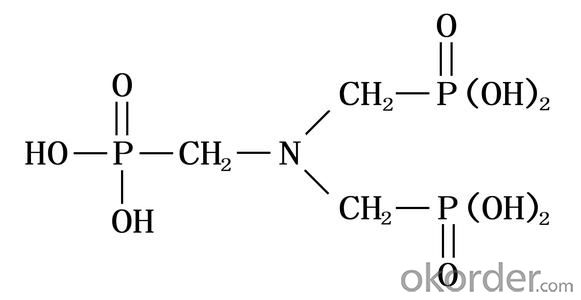

Amino tris(methylene phosphonic acid) / Amino Trimethylene Phosphonic Acid/ ATMP / 6419-19-8 / C3H12NO9P3

CAS No. 6419-19-8

Molecular Formula: N(CH2PO3H2)3

Molecular weight: 299.05

Structural Formula:

Properties:

ATMP has excellent chelation, low threshold inhibition and lattice distortion ability. It can prevent scale formation, calcium carbonate in particular, in water system. ATMP has good chemical stability and is hard to be hydrolyzed in water system. At high concentration, it has good corrosion inhibition.

ATMP is used in industrial circulating cool water system and oilfield water pipeline in fields of thermal power plant and oil refinery plant. ATMP can decrease scale formation and inhibit corrosion of metal equipment and pipeline. ATMP can be used as chelating agent in woven and dyeing industries and as metal surface treatment agent.

The solid state of ATMP is crystal powder, soluble in water, easily deliquescence, suitable for usage in winter and freezing districts. Because of its high purity, it can be used in woven & dyeing industries and as metal surface treatment agent.

Specification:

| Items | Index | |

|---|---|---|

| Standard | Solid | |

| Appearance | Clear, Colorless to pale yellow aqueous solution | White crystal powder |

| Active acid % | 50.0-51.0 | 95.0min |

| Chloride (as Cl-)% | 1.0 max | 1.0 max |

| pH value (1% solution) | 2.0 max | 2.0 max |

| Fe,mg/L | 10.0max | 20.0max |

| Density (20°C)g/cm3 | 1.31-1.35 | - |

| Colour APHA (Hazen) | 30.0max | - |

Application range&using method:

ATMP is usually used together with other organophosphoric acid, polycarboxylic acid and salt to built all organic alkaline water treatment agent. ATMP can be used in many different circulating cool water system. The recommended dosage is 5-20mg/L. As corrosion inhibitor, The recommended dosage is 20-80mg/L.

Package and Storage:

ATMP liquid: Normally In 30kg or 250kg net Plastic Drum;ATMP solid: 25kg inner liner polyethylene (PE) bag, outer plastic woven bag, or confirmed by clients request.Storage for ten months in room shady and dry place.

Safety Protection:

ATMP is Acidity, Avoid contact with eye and skin, once contacted, flush with water.

Shipping Date: Within 7-10 workdays after receiving your deposit.

Our Service:

Own Lab and joint venture factory.

Superb r&d team;Safety standardization production.

Rich experience in export and strong logistical support.

Good relationship with many large domestic pharmaceutical factory.

Perfect service, perfect supply chain.

- Q:What is positive and negative catalyst in chemistry?

- Negative catalysts are, on the other hand, slowing down the positive reaction rate at the same time

- Q:What is the reaction of hydrogen peroxide to add manganese dioxide?

- There are bubbles produced

- Q:The greater the chemical adsorption strength, the catalyst activity changes

- If the adsorbent is a reactant, then the better the adsorption capacity of the better catalytic effect; but the catalyst surface of the product will generally have adsorption, if this effect has become very strong, then desorption The process will become difficult, the catalytic effect will decline; the other one, if the adsorption of other substances, such as the reaction may produce a reaction or the catalyst will poison the material, it is greatly detrimental to the catalytic effect. The effect is to be controlled in a suitable optimum range for superior, and preferably to be selectively adsorbed.

- Q:CO and NO react under the action of a catalyst to generate chemical formulas for CO2 and N2.

- C from +2 to +4 price 2e * 2

- Q:Chemistry GCSE what is a catalyst?

- A catalyst is a substance added to a reaction to speed the reaction up!

- Q:Does the catalyst affect the chemical reaction rate constant? How does the chemical reaction rate constant change when a positive catalyst is added to a reaction?

- The positive catalyst will increase the constant, negat

- Q:I dont know what it is but when i open up my computer it comes up and it says that its not working? so i really dont know what to do.

- Catalyst is what ATI calls the drivers for their video cards or video devices built into mainboards. Download the newest video driver for your video card from ATI or from your computer manufacturer's site if the video device came with the computer. Install that, and you should be all set. You may want to check your add and remove programs and remove any of the old, malfunctioning ATI or Catalyst drivers before attempting to install the new one. Good luck!

- Q:The last question asked no one answered this question.

- This problem is difficult to answer comprehensively because the study of the different directions of the catalyst is different.

- Q:and can you give me an example of it .. please give it in easy terms if you can. thanks

- A okorder /... hope this helps!!

- Q:What chemical reactions can water do the catalyst?

- Many solid and solid reactions can be converted into reactions between liquids, which speeds up the reaction rate, and perhaps the water here is the catalyst.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Amino Trimethylene Phosphonic Acid China Supplier

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 6000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products