Amino Trimethylene Phosphonic Acid Best Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 6000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

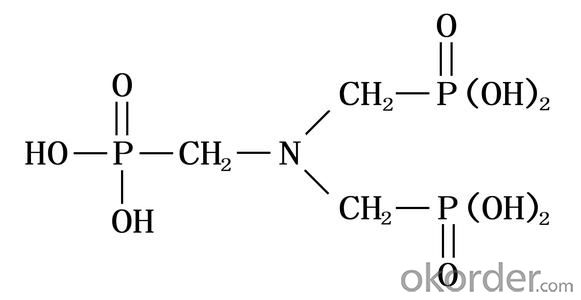

Amino tris(methylene phosphonic acid) / Amino Trimethylene Phosphonic Acid/ ATMP / 6419-19-8 / C3H12NO9P3

CAS No. 6419-19-8

Molecular Formula: N(CH2PO3H2)3

Molecular weight: 299.05

Structural Formula:

Properties:

ATMP has excellent chelation, low threshold inhibition and lattice distortion ability. It can prevent scale formation, calcium carbonate in particular, in water system. ATMP has good chemical stability and is hard to be hydrolyzed in water system. At high concentration, it has good corrosion inhibition.

ATMP is used in industrial circulating cool water system and oilfield water pipeline in fields of thermal power plant and oil refinery plant. ATMP can decrease scale formation and inhibit corrosion of metal equipment and pipeline. ATMP can be used as chelating agent in woven and dyeing industries and as metal surface treatment agent.

The solid state of ATMP is crystal powder, soluble in water, easily deliquescence, suitable for usage in winter and freezing districts. Because of its high purity, it can be used in woven & dyeing industries and as metal surface treatment agent.

Specification:

| Items | Index | |

|---|---|---|

| Standard | Solid | |

| Appearance | Clear, Colorless to pale yellow aqueous solution | White crystal powder |

| Active acid % | 50.0-51.0 | 95.0min |

| Chloride (as Cl-)% | 1.0 max | 1.0 max |

| pH value (1% solution) | 2.0 max | 2.0 max |

| Fe,mg/L | 10.0max | 20.0max |

| Density (20°C)g/cm3 | 1.31-1.35 | - |

| Colour APHA (Hazen) | 30.0max | - |

Application range&using method:

ATMP is usually used together with other organophosphoric acid, polycarboxylic acid and salt to built all organic alkaline water treatment agent. ATMP can be used in many different circulating cool water system. The recommended dosage is 5-20mg/L. As corrosion inhibitor, The recommended dosage is 20-80mg/L.

Package and Storage:

ATMP liquid: Normally In 30kg or 250kg net Plastic Drum;ATMP solid: 25kg inner liner polyethylene (PE) bag, outer plastic woven bag, or confirmed by clients request.Storage for ten months in room shady and dry place.

Safety Protection:

ATMP is Acidity, Avoid contact with eye and skin, once contacted, flush with water.

Shipping Date: Within 7-10 workdays after receiving your deposit.

Our Service:

Own Lab and joint venture factory.

Superb r&d team;Safety standardization production.

Rich experience in export and strong logistical support.

Good relationship with many large domestic pharmaceutical factory.

Perfect service, perfect supply chain.

- Q:Palladium is the main catalyst in chemistry?

- Palladium in the chemical mainly to do the catalyst; palladium and ruthenium, iridium, silver, gold, copper and other alloy, can improve the palladium resistivity, hardness and strength, used in the manufacture of precision resistors, jewelry and so on. While the most common and most commercially available palladium jewelery is palladium.

- Q:Why does the CuO catalyze the reaction rate faster and faster when catalyzing the decomposition of hydrogen peroxide or tell me how to make the catalyst catalyst faster

- CuO exothermates when catalyzing the decomposition of hydrogen peroxide, so the reaction becomes faster.

- Q:Why the catalyst is required to have a large surface area and a rich pore structure

- Has a large surface area, is the reactants and catalyst contact more fully, improve the catalytic effect

- Q:I need to name 3everyday catalysts for my chemistry homework. I don't want anything complicated there must just be 3 easy ones out there... Then could you please state what each one is used for? Please do it like this, e.g.Hello ; used to say hi to someone. I know that's a bad example but please!!

- Hello ; Chemical catalysts are substances that increase the rate of reaction (while remaining themselves chemically unchanged: Polyethylene, the polymer used to make everything from: 1. garbage bags and 2. grocery bags, to 3. squeezable bottles, to 4. cable insulation, is made by passing ethylene gas over a catalyst. Most other polymers are made in the same (or similar) way. Synthetic rubber, nylon, polyester, PVC, teflon, etc. It's not hard to think of 10 uses for these catalyst-produced materials alone... e.g. : 5. rain coats 6. pantyhose 7. water pipes 8. bouncy balls 9. non-stick surfaces and pads 10. saran wrap 11. food containers 12. cell-phone and laptop cases 13. cheap wigs 14. fishing line... 15. Enzymes are Biological catalysts: 16. beer and 17. bread are typically made with yeast, a living organism containing enzymes I hope this helps!

- Q:In the chemical calculation, the quality of the catalyst should not be counted before and after the reaction

- It is not the same .. because the quality of the catalyst will not change .

- Q:What is the quality of the catalyst in the chemical reaction, for example, 34.3 g before the hydrogen peroxide reaction, 32.7 g after the reaction, and how much is the catalyst mass?

- You can not calculate this question, the quality of the catalyst before and after the same reaction, how much reaction before the reaction on how much

- Q:How does active charcoal catalyze in some chemical reactions?

- It is a carrier, because its particles are small (micron level, nano-level), has a relatively large surface area, can be loaded on the catalyst to provide more reaction sites. Although called activated carbon, but its catalytic aspects of the relevant business reports.

- Q:what is a catalyst?

- Somthing that helps to speed things up. example: an enzyme is a biological catalyst, it speeds things up

- Q:and can you give me an example of it .. please give it in easy terms if you can. thanks

- a catalyst enables a reaction to occur quicker, by lowering the activation energy, and finding it an alternate path way to react. example of a catalyst is an enzyme, found in our saliva, it helps us digest our foods, by breaking it down into smaller pieces.

- Q:What is the difference between a catalyst and an oxidizing agent?

- A catalyst alters the rate of a reaction without being used up in the reaction. An oxidising agent oxidises other compounds, the agent itself being reduced in the process.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Amino Trimethylene Phosphonic Acid Best Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 6000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products