Aluzinc steel sheet building material composed of sheets

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 14567 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

ALUZINC Steel Sheet is carbon steel sheet coated with aluminum-zinc alloy by a continuous hot-dip

process. The nominal coating composition is 55% aluminum and 45% zinc. A small but important addition

of silicon is included in the coating alloy. It is added not to enhance the corrosion performance, but to

provide good coating adhesion to the steel substrate when the product is roll-formed, drawn, or bent during

fabrication.

While Galvalume has excellent durability in many settings, it should not be used adjacent to concrete or mortar.

Due to the high alkaline content in these environments, bare and painted Galvalume rapidly corrode.

Standard and Grade :

Hot-dip Aluzinc steel coils | ||||

ASTM A792M-06a | EN10327-2004 | JIS G 3321:2010 | AS- 1397-2001 | |

Commercial quality | CS | DX51D+AZ | SGLCC | G1+AZ |

Structure steel | SS GRADE 230 | S220GD+AZ | SGLC400 | G250+AZ |

SS GRADE 255 | S250GD+AZ | SGLC440 | G300+AZ | |

SS GRADE 275 | S280GD+AZ | SGLC490 | G450+AZ | |

SS GRADE 340 | S320GD+AZ | SGLC570 | G450+AZ | |

SS GRADE 550 | S350GD+AZ | G500+AZ | ||

S550GD+AZ | G550+AZ | |||

Application :

Production of cold formed corrugated sheet and profiles for roofing, cladding, decking, tiles, sandwich

walls, rainwater protective systems, air conditioning duct as well as electrical appliances and engineering.

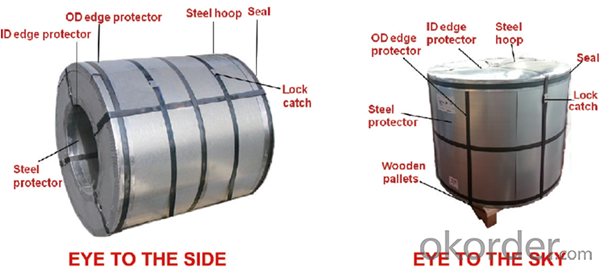

Packaging & Shipping

Packaging Detail | The packing of coil consists of anti-damp paper ,PVC film ,hardboard paper , steel box , strapped with steel strips, fitted with locks and edge protectors and guarantees the optimal condition of the delivered goods. Each coil can be additionally fitted with wooden/steel skids(eye of the side) or wooden pallets(eye of the sky) |

Delivery Time | within 30 days of receipt of LC original or prepayment |

Our Services

MOQ | FCL, 25 metric tons per 20GP, can be assorted with different sizes. |

LCL for trial order is acceptable. | |

Price Term | EX-WORK, FOB China Port, CNF, CIF |

Payment | T/T, 30% advanced payment before production and balance before shipment; OR Irrevocable L/C at sight. |

Delivery Time | within 30 days of receipt of LC original or prepayment |

FAQ

Q: How do you guarantee the quality of your product?

A: Every process will be checked by responsible QC which insures every product's quality.

Q: How much is your delivery time?

A: Normally within 30 days of receipt of LC original or prepayment, but mostly according to the

specific requirements or the quantity

Q: I need sample, could you support?

A: We can supply you with the sample for free, but the delivery charges will be covered by our customers.

For avoiding the misunderstanding, it is appreciated if you can provide the International Express Account for

Freight Collect. Also you can have a visit to us, welcome to CNBM!

- Q:How do steel sheets perform in terms of electromagnetic shielding?

- Steel sheets are highly effective in terms of electromagnetic shielding due to their strong conductivity and ability to reflect and absorb electromagnetic waves. They can block and redirect electromagnetic fields, reducing their impact on nearby electronic devices or sensitive equipment.

- Q:Can steel sheets be used for automotive exhaust systems?

- Yes, steel sheets can be used for automotive exhaust systems. Steel is a common material for exhaust systems due to its durability, resistance to heat and corrosion, and cost-effectiveness. Steel sheets are often formed into pipes, mufflers, and other components of the exhaust system to efficiently channel and expel exhaust gases.

- Q:How are steel sheets packaged for shipping?

- Typically, steel sheets are packaged in a manner that guarantees their protection during transportation. This is achieved through a series of steps aimed at preventing any damage or deformation that may occur during transit. To start, the steel sheets are commonly stacked on wooden pallets or placed in sturdy steel crates. This serves to create a stable base and prevents any movement or shifting of the sheets during transportation. Additionally, the use of pallets or crates facilitates the loading and unloading of the sheets onto trucks or containers. To further safeguard the steel sheets from scratches or other forms of surface damage, they are often wrapped with a layer of protective material. This can include plastic wraps, paper or cardboard interleaves, or even an application of oil or rust inhibitor. These protective materials act as a barrier, preventing any direct contact that could potentially cause scratches. Furthermore, steel sheets may be securely bundled together using steel strapping or wire. This bundling process helps to maintain the structural integrity of the sheets and prevents them from shifting or sliding during transportation. Lastly, once the steel sheets are appropriately packaged, they are typically labeled with pertinent information such as product specifications, quantity, and destination. This ensures ease of identification and proper handling at each stage of the shipping process. In summary, the packaging of steel sheets for shipping is meticulously carried out to ensure their safe and secure transportation. By utilizing pallets or crates, protective materials, bundling, and labeling, steel sheets can withstand the demands of shipping and reach their destination in optimal condition.

- Q:How are steel sheets manufactured?

- Steel sheets are manufactured through a process called hot rolling, where a large steel slab is heated and passed through a series of rollers to reduce its thickness and achieve the desired dimensions. The hot rolling process involves reheating the slab, which is then fed into a roughing mill to reduce its thickness. It is then passed through a series of tandem mills to further reduce the thickness and achieve uniformity. The final product is coiled into large rolls or cut into smaller sheets, ready for various industrial applications.

- Q:Can steel sheets be used for structural purposes?

- Yes, steel sheets can be used for structural purposes. Steel is a strong and durable material, and when formed into sheets, it can provide structural support in various applications such as building construction, bridges, and automotive manufacturing. The versatility of steel sheets allows for customization and ease of installation, making them a popular choice for structural purposes.

- Q:How can steel sheets be protected from corrosion?

- Steel sheets can be protected from corrosion through various methods such as applying protective coatings like paint or galvanization, using corrosion inhibitors, implementing cathodic protection, or utilizing stainless steel with inherent corrosion resistance.

- Q:Where can steel sheets be purchased?

- There are numerous places where one can acquire steel sheets. Local hardware stores, home improvement centers, and metal supply companies are among the common choices. These places typically provide a variety of steel sheet sizes and thicknesses for customers to choose from. Furthermore, the convenience of buying steel sheets online should not be overlooked. Online retailers and e-commerce platforms offer a wider range of options and competitive prices. To ensure you get the most value for your money, it is crucial to compare prices, quality, and customer reviews before making a purchase.

- Q:What is the maximum width of steel sheets?

- The maximum width of steel sheets can vary depending on the manufacturer and the specific requirements of the project. However, standard steel sheet widths typically range from 36 inches to 72 inches.

- Q:How are steel sheets protected during storage and handling?

- Steel sheets are protected during storage and handling through various methods to prevent damage and ensure their quality. One of the most common ways to protect steel sheets is by using a protective coating or oil. This coating acts as a barrier against moisture and other environmental factors that can cause corrosion or rust. Steel sheets are often stored in covered warehouses or storage areas to shield them from direct sunlight, rain, and other weather elements. This helps to prevent any potential damage to the sheets and maintain their integrity. During transportation and handling, steel sheets are typically lifted using cranes or forklifts with appropriate lifting equipment to avoid any bending or twisting. They are also properly secured and stacked in a way that minimizes the risk of damage or deformation. In addition, steel sheets are often packaged using materials such as plastic or cardboard to provide further protection against scratches or other physical damage. They may also be wrapped or sealed to prevent any contact with moisture or other contaminants. Overall, the goal is to ensure that steel sheets are kept in a safe and controlled environment during storage and handling to maintain their quality and prevent any potential damage that could compromise their performance in future applications.

- Q:How are steel sheets packaged for shipping?

- Steel sheets are typically packaged for shipping in a way that ensures their protection during transportation. The packaging process involves various steps to prevent any damage or deformation that may occur during transit. Firstly, the steel sheets are usually stacked on wooden pallets or placed in sturdy steel crates. This helps to provide a stable base and prevents any movement or shifting of the sheets during transportation. The use of pallets or crates also makes it easier to load and unload the sheets onto trucks or containers. To further protect the steel sheets from scratches or other forms of surface damage, they are often covered with a layer of protective material. This can include plastic wraps, paper or cardboard interleaves, or even a layer of oil or rust inhibitor. These protective materials act as a barrier between the steel sheets, preventing any direct contact that may cause scratches. Additionally, steel sheets may be bundled together with steel strapping or wire to keep them securely in place. This bundling process helps to maintain the structural integrity of the sheets and prevents them from shifting or sliding during transportation. Finally, once the steel sheets are properly packaged, they are typically labeled with relevant information such as product specifications, quantity, and destination. This ensures that the sheets can be easily identified and handled correctly at each stage of the shipping process. Overall, the packaging of steel sheets for shipping is carefully done to ensure their safe and secure transportation. By using pallets or crates, protective materials, bundling, and labeling, steel sheets can withstand the rigors of shipping and arrive at their destination in optimal condition.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Aluzinc steel sheet building material composed of sheets

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 14567 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords