Aluminum Zinc Rolled Coil for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

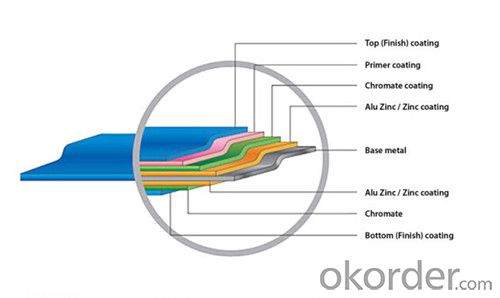

Structure of Aluminum Zinc Rolled Coil

Description of Aluminum Zinc Rolled Coil

Standard | ASTM A653, JIS G3302,GB/T3830-2006 |

Grade | DX51D,SGCC,SPCC,SGHC |

Thickness | 0.18mm--1.2mm |

Width | 400-1250mm(usual size:914mm,1000mm,1200mm,1219mm,1250mm,) |

Base metal | Galvanized steel coils |

Zinc coating | 40-80gsm |

Coil ID | 508mm,610mm |

Coating thickness | Top:17-25um back:5-8um |

Color options | Ral number or as per your request |

Packing | 3 Layer Standard seaworthy export packing: Inside is kraft paper ,water plastic film in the middle Outside GI steel sheet to be covered by steel strips with lock inner coil sleeve. |

Main Feature of Aluminum Zinc Rolled Coil

Corrosion resistance

Weather resistance

Long working life

Good formability

Applications of Aluminum Zinc Rolled Coil

1. Construction and building: roofing; ventilating duct; handrail; partition panel;etc.

2. Electric appliance: refrigerator; washing machine; refrigerator; DVD;etc.

3.Transportation: oil tank; road sign; etc.

4.Agriculture:barn; etc.

5.Others:vending machine; game machine; etc.

Aluminum zinc rolled coil images

FAQ of Aluminum Zinc Rolled Coil

We have organized several common questions for our clients,may help you sincerely:

1. What is the minimum order quantity ?

Our MOQ is 50mt for each size. And we will consider to give more discount if you make big order like 1000 tons and more. Further more, the more appropriate payment term your offer the better price we can provide.

2. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q:Are steel coils used in the aerospace industry?

- Yes, steel coils are used in the aerospace industry for various applications such as manufacturing aircraft components, structural parts, and engine components.

- Q:I was wondering if anyone knew the grade/type of steel for this product. I'd like to use it as stock for a knife blade, but would like to know the specs so I can determine if it is suitable and, if so, how best to heat treat it.Thanks.PS: I know it isn't stainless, but that leaves a lot of other steel types.

- That isn't good steel for a functional knife. But that doesn't mean its useless to you. It makes for cheap and easier practice. Its a good idea to screw up a couple of cheap pieces of steel before you start buying expensive blanks. The mild steel will be easier to work with too, so its a good start towards being able to shape a harder piece. Practice a few times withcheap, soft steel. Get to know your tools. At some point the steel will be limiting your abilities. Then its time to start buying the expensive stuff. Steel can be hardened by introducing carbon when the steel is above a certain temp. But its difficult and a little unsafe in uncontrolled conditions. Really not worth bothering with.

- Q:How are steel coils inspected for weldability using welding tests?

- A range of welding tests can be utilized to inspect steel coils for their weldability. The bend test is a common approach where a segment of the coil is cut and bent to assess the weld's quality. This evaluation helps identify any brittleness or flaws that could compromise its integrity. Furthermore, the guided bend test is conducted to evaluate the weld's ability to endure bending without cracking or breaking. Another technique employed is the macro etch test, which involves cutting a cross-section of the coil and applying a chemical solution to etch it. This test effectively exposes imperfections or irregularities in the weld, such as porosity, slag inclusions, or fusion deficiencies. Moreover, the hardness test measures the weld's hardness, which is crucial as excessive hardness can lead to cracking or brittleness, while insufficient hardness may cause weld failure under specific conditions. Additionally, non-destructive testing methods like ultrasonic testing, magnetic particle inspection, or radiographic examination can be employed to detect internal defects, such as cracks or voids, in the steel coil welds without causing any damage to the material. Conducting comprehensive inspections through these welding tests is essential to ensure the quality and weldability of steel coils before their use in various applications. By identifying and addressing potential issues, these inspections guarantee that the steel coils meet the necessary standards for weldability and structural integrity.

- Q:What are the dimensions of steel coils used in the storage tank industry?

- The dimensions of steel coils used in the storage tank industry can vary depending on the specific requirements of the tank being manufactured. However, in general, steel coils used for storage tanks are typically available in various sizes and thicknesses. The width of steel coils can range from around 600 millimeters to 2,400 millimeters, while the length can vary from several meters to tens of meters. The thickness of the coils can also vary, typically ranging from 1.5 millimeters to 10 millimeters or more. These dimensions are determined by factors such as the size and capacity of the storage tank, the material being stored, and the structural requirements of the tank. The specific dimensions for a given storage tank project would be determined by the tank manufacturer or designer, in accordance with industry standards and specific project specifications.

- Q:What are the different methods of coil welding for steel coils?

- There are several different methods of coil welding for steel coils, including resistance welding, laser welding, and induction welding. Resistance welding involves applying pressure and passing an electrical current through the coils to create a weld. Laser welding utilizes a high-powered laser beam to melt and fuse the edges of the coils together. Induction welding involves using electromagnetic fields to heat and fuse the coils. Each method has its own advantages and is chosen based on the specific requirements of the application.

- Q:Ok, so I'm obsessed with learning how to play the guitar (I preffer acoustic)... I'm a teenage girl that wants to play rock/pop/folk music... I want to learn first how to strum... then eventually how to pick...so what type of string is better? nylon or steel?

- A good number of teachers (in No.California) recommend nylon string guitars for beginner students for the following reasons: 1: Either (nylon strings or steel strings) type of acoustic guitar can play ANY type of music However,nylon strings are much easier (less punishing) on the fingers as well as you start learning to use your fingers (not a pick )to play. Many beginners with the steel-string like to start right away with the use of a pick to avoid the hardness of the steel strings and seldon move up to learn to use the bare fingers to play. 2: For those concern about volume many classical acoustic are built with an electric plug that can be utilize to hook into an amplifiying unit. 3: Once you learn to finger-play you are ahead of some players that started with a pick and have a difficult time to play without a pick. 4: Right hand (if a right-handed)finger dexterity is very important in playing the melody passages (harmony that depends primarily on chords) of any musical piece. 5: It is true that a nylon-string guitar brings out a more mellower sound and the steel-strings have a brighter (but tin-like) sound. Both can be heard clearly in a standard living room environment without need of amplification. In the final analysis is a matter of personal choice. Most of my profesional guitar player friends have and play often both types of guitars. They play the nylon-string when in a group of players and they are assigned the 1st guitar music part. When they are playing harmony (back up) they seem to play more the steel-string instrument. A note of interest: Every player I know that plays classical guitar knows how to sight-read music while most other players that only play with a pick and steel-strings guitar use Tabs for playing. Either way it is you that have to decide. Try both instrument in the same piece of music (or strumm on both) and see which one you like. Good Luck and Enjoy whatever guitar you choose.

- Q:What are the common surface finishes available for steel coils?

- The common surface finishes available for steel coils include hot-dip galvanized, galvannealed, electro-galvanized, and painted finishes.

- Q:What are the safety regulations for handling steel coils?

- The safety regulations for handling steel coils include wearing appropriate personal protective equipment, such as gloves and steel-toed boots, using proper lifting techniques and equipment, ensuring a clear and organized work area, and following guidelines for stacking and securing coils to prevent accidents and injuries. Regular inspections and maintenance of equipment and storage areas are also crucial for ensuring safe handling of steel coils.

- Q:How are steel coils used in the production of gutters and downspouts?

- Steel coils are used in the production of gutters and downspouts by being shaped and formed into the desired size and shape of the gutters and downspouts. The coils are unrolled and passed through a roll-forming machine, which cuts and bends the steel into the required profile. This process allows for the efficient and cost-effective production of gutters and downspouts with high durability and strength, ensuring their ability to withstand various weather conditions.

- Q:Are steel coils used in electrical equipment manufacturing?

- Yes, steel coils are commonly used in electrical equipment manufacturing. Steel coils are often used as core material in transformers, motors, and generators due to their magnetic properties and ability to efficiently transfer electrical energy. They provide structural support and help enhance the performance and efficiency of electrical equipment.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Aluminum Zinc Rolled Coil for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords