Aluminum Window and Door Factory with ISO CE etc

- Loading Port:

- Guangzhou

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 set

- Supply Capability:

- 1000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Descriptions for Aluminum window and door

Our window system features good sound insulation,better in energy-saving and comprehensive after-sale service.

A.Adopt 14.8mm or other type heat insulation strip.

B.Suitable for the area with high performance heat preservation, heat insulation .

C.Sash width ≥300mm;Sash height≤2400mm;Weight of window sash ≤250kg.

D.Side frame, follow the procedure of glue injection after corner crimping; Leading the flow of Sealant through sealant guide plate, increasing the intensity and Sealing performance of window corner.

E.Sash frame use plastic corner key connect through inside hexagonal bolt, easy connection, simples construction, less fabrication process, suitable for quantitive production and it’s very convenient to be changed for the dimension of sash and frame.

F.For more options from 16-22mm glazing.

G.Heat insulation can be achieved as 2.0W / m² k ~ 2.5W / m² k.

H.Beautiful shape, elevation effect concise and bright.

I.Use excellent hardware ,flexible opening, tiny opening and closing force, opening deft and agile, without noise.

J.Sealing design with anti-crash piece, Prevent shaking piece as an whole, convenient installation.

2. Specifications for Aluminum window and door

1. Material | Aluminium ingot; 6063, 6061, 6082, 6005, T5, T6, |

| 2. Section Shapes | I, U, T, C, Z, L, H, square, round, flat, hollow, t-slot and other complicated shapes by custom design. |

| 3. Surface treating | Mill/Anodized(oxidation)/Sand blast/Powder coating/Electrophoresis/Wood grain. |

| 4. Application | 1) - for Window and door frames |

| 2) - for Wardrobe cabinet sliding doors, kitchen. | |

| 3) - for Building curtain glass walls | |

| 4) - for Solar panel frames, Solar mounting / roofing brackets | |

| 5) - for Industry assembly lines equipment. | |

| 6) - for Heatsinks | |

| 7) - for LED lighting | |

| 8)- other by custom design size and dimension | |

| 5. Production lines | 1) 5 melting and casting production lines |

| 2) 25 extruding production lines | |

| 3) 6 anodizing and electrophresis production lines | |

| 4) 2 powder coating production lines | |

| 5) 4 wooden grain production lines | |

| 6) 2 heat insulation broken bridge production lines | |

| 7) 2 wiredrawing and polishing production lines | |

| 6. Characteristic Services | 1). OEM Service. |

| 2). Design according to the customers' requirements. | |

| 3). more years' professional experience in research, manufacturing | |

| 4). Our modern deep processing center can provide machining such as Cutting, punching, drilling, etc. | |

| 7. Quality Control | We operate the most strict quality control system, the detection is from the material, production process, |

| to final product, and ensure the product quality and traceability. | |

| 8.Process | Die design→Die making→Smelting&alloying→QC→Extruding→Cutting→Heat Treatment→ |

| QC→Surface treatment→QC→Welding→Packing→QC→Shipping→After Sale Service | |

| 9.Standard | GB5237-2008 equal to EN12020-1.2(2001) |

| 10.Payment | T/T: 30% for deposit, the balance will be paid before delivery |

| 11.Delivery Time | 1. 15-35 days production. |

| 2. If making a mould, plus 7~10 days. | |

| 12.Packaging Detail: | Inside : packed with plastic film to protect each piece |

| Outside: Wrap to be bundles by waterproof craft paper or EPE film. Customized request available | |

| 13.Lead Time | Die Developing and Sample testing: 12-18 days . |

| Mass Production: 20-30days. |

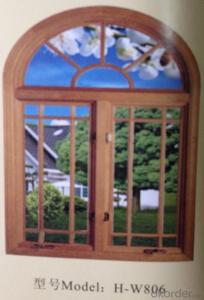

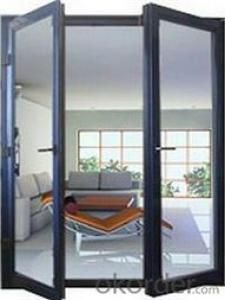

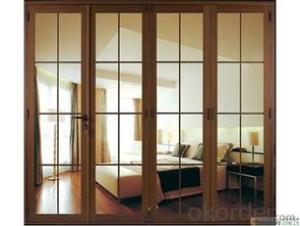

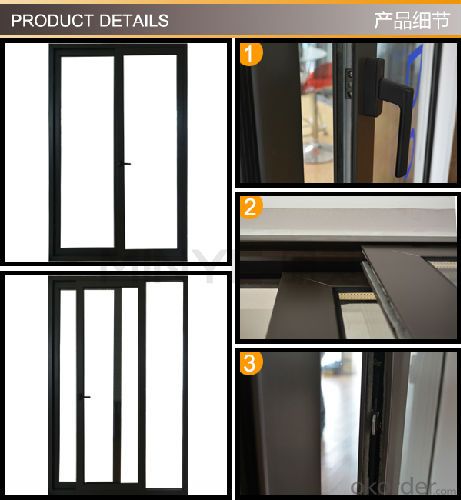

2. Photo for Aluminum window and door

- Q:How much can the sill plate pull out?

- Depending on the material, size, and the use of the situation, to determine. If the windowsill board to force the future, such as standing, put flower pots, etc., the size of the outer probe is best than half of the windowsill. If not appropriate may be appropriate, it is best not to be greater than a quarter, more than one-half of the risk of falling.

- Q:Sliding window is not a fixed window?

- Hello, the sliding window is not a fixed window, the so-called fixed window is fixed glass in the glass can not move on top of the glass, and can generally enhance the lighting of office space

- Q:What is the material for the door stone and the windowsill?

- sure! Artificial marble is made of plastic and stone powder, artificial marble health, will not change color, easier to clean, no radiation, natural marble texture hard, colorful, shades, there are a variety of shiny, so the formation of a unique natural beauty. Artificial marble than natural marble light weight, high strength, thin thickness, corrosion resistance, anti-pollution, a better processing, can be made curved, curved surface, easy construction. But in the color and texture is less than natural marble beautiful, natural soft. "I am worried about the issue of stone radiation," I answered this question much better, you can find the search in the station. Other materials: granite, mostly radiation, but within the allowable range are safe; metal materials, less aesthetic, easy to produce scratches on the surface; wood material, not wear, durability, poor weather resistance. Go through the stone is the stone threshold --- to solve the internal and external height difference, to solve the transition between the two materials, blocking water, from the aesthetic role of a slate. Stone corner is usually done "chamfer", that is, grinding a bevel, the same is for the beautiful and convenient. Stone stone stone is recommended to use granite, granite material than marble hard, resistant to tread. If there is a side of the ground (usually the bathroom outside the side) there are stone floor parquet or stone floor ring edge, can also use the same or the same material, more beautiful. Common cheap, strong, good color with the stone for the town of black (Inner Mongolia), Jinan green, sesame ash and so on. The windowsill is made of natural marble. Artificial marble is generally used for kitchen, toilet platen, easy to clean.

- Q:Why the windowsill under the beam?

- Under the windowsill should be called "pressure top", the general width and wall width, length is greater than the window hole 400mm, that is, one side to the wall 200mm, mainly used to reinforce the window under the brick wall, fixed aluminum window nail nail in the windowsill Above the top of the concrete, so that aluminum windows are fixed above and below the concrete, the side of the window is only fixed on the brick wall.

- Q:Winter windowsill will be moldy around ah, the window is always dripping, would like to ask you when the windows are how to handle the decoration?

- Stone windowsill, metal package edge, can be. The window dripping is condensed and the double glass will improve a lot.

- Q:The windowsill marble countertops are thicker

- You say it is the original thickness of the plate or that thick side ah. Plate thickness, then I know that is 16.5mm thick side of the words according to its different thickness of the different styles.

- Q:What kind of material is the best of the countertops?

- Artificial stone countertops Artificial stone, also known as polymer solid board, is the use of natural ore powder + color masterbatch + acrylic resin, high temperature, high pressure treatment of the plate, uniform texture, no pores, the market is recognized as the most suitable for modern kitchen Of the cabinet panel material. Advantages: Artificial stone more wear-resistant, acid, high temperature, impact, compression, bending, anti-penetration and other functions are also very strong. Its deformation, bonding, turning and other parts of the treatment is unique; rich color, the overall shape, and can be repeated polished renovation. So the stain is strong, because the surface without pores, oil, water stains are not easy to penetrate them, the general stains can be wiped with a damp cloth or detergent can be any length of seamless bonding, with the material of the adhesive will be two Adhesive after grinding, seamless, no trace at the seam. Disadvantages: nature is clearly inadequate, the texture is relatively false; the price is higher. special reminder Even if it is seamless artificial stone, because of its different processing technology, the quality is also divided into three six nine, so in the choice of certain pick credibility is better, the service has guaranteed the brand. The industry suggested that, according to cost, it is best not to consider less than 1,000 yuan of artificial stone.

- Q:Is the bathroom window tiles originally finished tiles to prepare the tiles to prepare the windowsill according to marble Some people say that marble will be more and one waterproof and no tiles good tiles and feel the overall comparison of agile tangled ah

- According to personal preferences, I think it is better to use tiles, because the tile is a close to mature products, with the life and waterproof effect is very good, and Naisuan Jian.

- Q:My home windowsill is a piece of marble windows and windowsill gap between the rain and rain into the house where the rain .... what methods are useless which experts know how to solve the solution please advise!

- If you did not press before you said Now can only use glass glue seal or marble glue this is only a remedy

- Q:Window beam and the difference between the beam, there is not every layer should ring beam?

- Ring beam is in the housing of the cornice, the top of the window, floor, crane beam roof or the top of the base elevation, along the masonry wall in the horizontal direction of the structure of reinforced concrete beam structure. Is a continuous closed beam that is provided along the walls of the building and around the interior wall. Its purpose is to enhance the overall stiffness of the building and the stability of the wall. The ring beam can reduce the adverse effects on the building due to uneven settlement of the foundation or the greater vibration load and the wall cracking caused by it. In the seismic fortification area, the use of ring beam reinforcement wall is even more necessary.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Aluminum Window and Door Factory with ISO CE etc

- Loading Port:

- Guangzhou

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 set

- Supply Capability:

- 1000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords