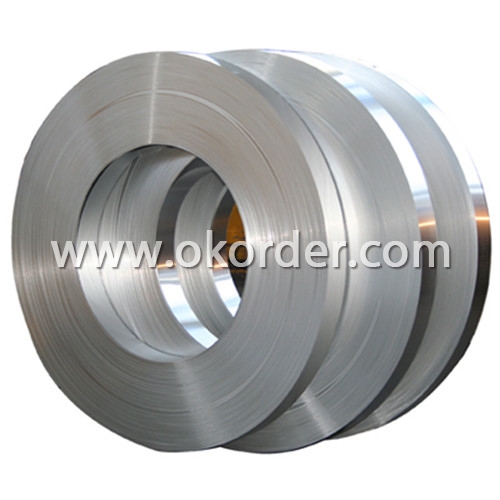

Aluminum Strips AA8006

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 Tons m.t.

- Supply Capability:

- 1000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Specifications of Aluminum Strips AA8006

Alloy Number | AA8006 |

Temper | Temper H12, H14, H16, H18, H22, H24, H26, H32,HO, F |

Thickness | 0.10-500mm |

Diameter | 10mm- 2200mm |

Standard | GB/T3880-2006, ASTM, ISO, EU standard |

Special specification is available on customers' requirements.

2. Usage/Applications of Aluminum Strips AA8006

Aluminum strips are widely used for PS printed materials substrate, building decoration materials, stamping products, building mirror materials, nameplate, insulation materials, aluminum plastic composite material, capacitor strip, transformer strip, welding parts, heat exchanger, clock surface and disk, kitchen utensils, reflecting apparatus etc.

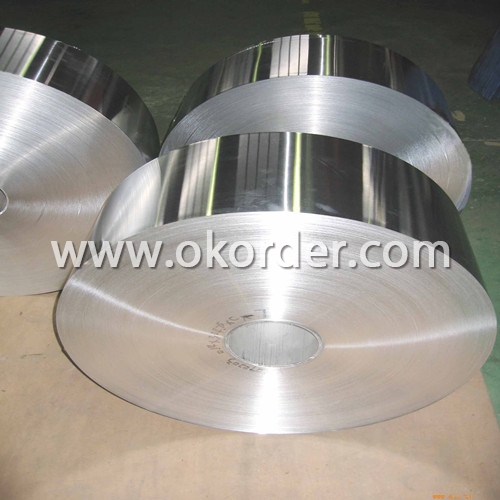

3. Packaging & Delivery of Aluminum Strips AA8006

Packaging: Seaworthy package, bubble plastic bag inside, anti-moisture paper wrapped outside, covered with cartons, on wooden pallets, in containers. Pallet weight: Max. 2.30 tons.

Shipment: the goods will be delivered in 30 days after getting the buyer's payment.

4. Production Flow of Aluminum Strips AA8006

Rolling--Annealing--Slitting—Sawing, Cut-To-Length, Shearing

- Q:How does the excavator aluminum belt turn in place?

- This is how it works1. Support the front half of the track with the bucket, so that half or more of the track is out of the ground2, turn the operating lever in the opposite direction of the desired turn, and then turn the track

- Q:What gas is best for welding aluminum strip?

- If the welded aluminum strip is welded by argon arc welding, it is best to use high purity argon and 5 purity of 9.

- Q:Why is the president of aluminum strip mildew, will affect the performance of the transformer?

- Aluminum with long mildew is actually aluminum is oxidized, the conductivity of alumina is lower than aluminum, so the resistance increases, resulting in increased contact surface heating, may endanger the insulation of the transformer will reduce the performance.

- Q:Would you like to buy a sensor for measuring the thickness of aluminum ribbon?

- ZTMS08 system has been optimized through performance and field calibration, and its main technical specifications and performance parameters comply with the relevant regulations. It can be widely used for thickness measurement of paper, paperboard and other sheet materials.

- Q:What kind of mask is good for welding aluminum strips?

- The welding aluminum strip will produce certain peculiar smell and aluminum chip. Can solve this problem at the same time, activated carbon mask can solve, activated carbon can absorb some peculiar smell, at the same time can come dust.

- Q:Which is better, an aluminum belt excavator or a tire excavator?

- Crawler excavator horsepower (generally 220 horsepower or more), more than the mountain or the ground soil construction complex engineering, mining, large accident rescue; tire excavator is generally used in municipal engineering construction, small horsepower.

- Q:Aluminum tape spraying process, please?

- Curing. The workpiece after spraying is sent into a baking chamber at 180~200 DEG C to heat it and solidify the powder(7) cleaning. After the coating is solidified, remove the protective material and trim the burr

- Q:How much is the small aluminum belt excavator?

- There are many types of small tracked vehicles, but I don't know which one you want.

- Q:The role of aluminum strip in tanks

- Because of the tread on the track, and can install thorns, so in the rain, snow, ice or uphill road.

- Q:How can the aluminium band be welded to the steel shell?

- Welding method:1) to deal with the surface of the aluminum strip and steel shell surface oil and oxide skin.2) after the low temperature welding wire 303B Wei Odin flatto, then put between the aluminum strip and steel shell.3) the resistance is placed in the welding place where the flat 303B wire is welded.4) in the premise of high temperature continuous heating, 303B welding wire melting forming, bonding aluminum strip and steel shell.Welding attention method:1, resistance welding current output must be enough, otherwise the parent can not reach the temperature, welding wire will not be adhesive.2, the surface of the oxide film must be handled clean, so that the aluminum band is easy to glue, otherwise, the aluminum oxide film will hinder the welding line bonding aluminum belt.

1. Manufacturer Overview |

|

|---|---|

| Location | Henan, China |

| Year Established | 1996 |

| Annual Output Value | Above US$200 Million |

| Main Markets | Mid East;Eastern Europe;North America |

| Company Certifications | ISO 9001:2000;ISO 14001:2004;OHSAS 18001 |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 30%-50% |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English;Chinese |

| b)Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | Average |

Send your message to us

Aluminum Strips AA8006

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 Tons m.t.

- Supply Capability:

- 1000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords