Aluminum Sheets D.C 1XXX

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 8 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Aluminum Sheets D.C 1XXX Description

Aluminum Sheets D.C 1XXX is cut from aluminum coils 1xxx. The aluminum content of Aluminum Sheets D.C 1XXX is 99% at least. It has great ductility, heat conductivity, anti-corrosion and moisture resistance properties.

Aluminum Sheets D.C 1XXX is widely used for electronics, instruments, lighting decoration, packing industry, house decoration, curtain wall, honeycomb-core panel, sandwich panel, aluminum composite panel and aluminum composite pipes.

2.Main Features of the Aluminum Sheets D.C 1XXX

• Superior quality of raw material

• Reasonable and stable chemical composition

• Accurate tolerance

• Goode mechanical property

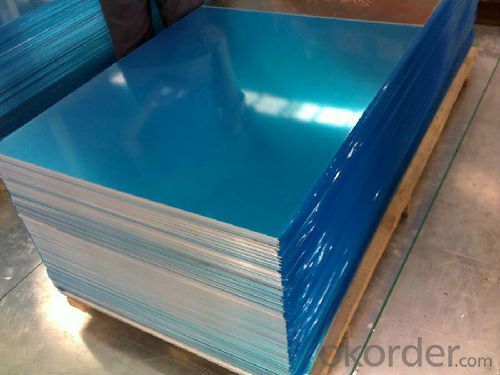

3.Aluminum Sheets D.C 1XXX Images

4.Aluminum Sheets D.C 1XXX Specification

| Alloy | AA1xxx (AA1050,AA1060,AA1070,AA1100 etc |

| Tmeper | H14, H16, H18, H22, H24, H26, H32, O/F |

| Thickness | 0.2mm-100mm |

| Width | 30mm-1700mm |

| Standard | GB/T 3880-2006 |

5. FAQ of Aluminum Sheets D.C 1XXX

A.How to guarantee the quality?

Customers are welcome to our mill to visit and check the products. Besides, we can arrange a third party to test the Aluminum Sheets D.C 1XXX products.

B. Now which countries do you export your goods?

Now we export to South East Asia,Africa, North America,South America ect.

- Q:Are the aluminum sheets suitable for manufacturing electronic enclosures?

- Yes, aluminum sheets are suitable for manufacturing electronic enclosures. Aluminum is lightweight yet sturdy, providing excellent protection for electronic components. It is also corrosion-resistant, making it suitable for various environments. Additionally, aluminum is a good conductor of heat, allowing for effective thermal management in electronic enclosures.

- Q:Can aluminum sheet be welded?

- Indeed, welding aluminum sheet is feasible. Aluminum, a versatile metal, lends itself well to welding through the utilization of diverse techniques like gas tungsten arc welding (GTAW), gas metal arc welding (GMAW), and resistance spot welding (RSW). Nevertheless, the welding of aluminum necessitates specific considerations due to its elevated thermal conductivity and low melting point when compared to other metals. Consequently, selecting the suitable welding process, filler material, and shielding gas is crucial to ensuring a successful weld. Moreover, proper surface preparation, including thorough cleaning and the removal of any oxide layer, plays a pivotal role in achieving a robust and long-lasting weld in aluminum sheet.

- Q:How does aluminum sheet perform in corrosive environments?

- Aluminum sheet performs exceptionally well in corrosive environments due to its inherent corrosion resistance. When exposed to moisture or various chemicals, aluminum forms a protective oxide layer that prevents further corrosion. This makes it a preferred choice for applications where resistance to corrosion is crucial, such as marine environments, chemical processing plants, and outdoor structures.

- Q:what kind of aluminum sheet is suitable for aluminum alloy double-edged saw?

- saw web size depends on the thickness and height of sectional material,equipment compatibility and permitted installed saw web size .

- Q:Are 101 aluminum sheets suitable for mold making?

- No, 101 aluminum sheets are generally not suitable for mold making. While aluminum is a commonly used material for making molds due to its durability and heat resistance, 101 aluminum is a low-strength alloy that may not meet the requirements for mold making. For such purposes, it is recommended to use aluminum alloys with higher strength and hardness, such as 6061 or 7075 alloys. These alloys offer better resistance to wear, deformation, and heat, making them more suitable for creating molds that can withstand the pressures and temperatures involved in the molding process.

- Q:I have no idea, and I can't figure this out, and neither can my aunt and she's super smart. It's this project that's due on Monday, and if I can't get it turned in, then I get detention and a failing lab grade. The only information I have is it's $2.96 for a roll of aluminum, it contains 2.96 square meters, and it weighs .995 grams...

- say it's a trick question, because it there is no denotational value for a single aluminum atom :/

- Q:Can aluminum sheets be used for industrial shelving?

- Certainly, industrial shelving can indeed make use of aluminum sheets. Aluminum, being a material that is lightweight and durable, offers numerous benefits for industrial shelving applications. It possesses resistance against corrosion, making it suitable for environments that face exposure to moisture or harsh chemicals. Moreover, the strength-to-weight ratio of aluminum proves advantageous, enabling the creation of robust shelves capable of supporting heavy loads while remaining relatively light in weight. Furthermore, aluminum is low-maintenance as it does not necessitate painting or sealing like other metals. Consequently, aluminum sheets are an incredibly practical option for industrial shelving due to their durability, resistance to corrosion, and lightweight characteristics.

- Q:What are the different methods of joining aluminum sheets without welding?

- There are several methods of joining aluminum sheets without welding, including adhesive bonding, mechanical fastening (such as screws or rivets), clinching, and using non-welding techniques like friction stir welding or laser welding.

- Q:Can aluminum sheets be bent?

- Yes, aluminum sheets can be bent. Aluminum is a highly malleable metal, which means it can be easily shaped or formed using techniques such as bending, rolling, or folding. The process of bending aluminum sheets involves applying force to the metal in order to create a desired angle or curve. This can be done by using specialized tools such as a brake press or by using manual techniques. The flexibility of aluminum makes it a popular choice for various applications where bending or shaping is required, such as in construction, automotive, or aerospace industries.

- Q:How do aluminum sheets perform in terms of electrical conductivity?

- Aluminum sheets are known for their excellent electrical conductivity. They are highly conductive, ranking second only to copper in terms of electrical conductivity among common metals. This high conductivity makes aluminum sheets an ideal choice for various electrical applications, including wiring, power transmission, and electrical components. The low resistivity of aluminum allows for efficient transfer of electricity, ensuring minimal energy loss during transmission. Additionally, aluminum sheets are lightweight, making them a preferred material for electrical systems where weight reduction is desired. Overall, aluminum sheets offer exceptional electrical conductivity, making them a reliable and efficient choice for electrical applications.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Aluminum Sheets D.C 1XXX

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 8 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords