Aluminum Sheets AA1070 Used for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

1.Structure of Aluminum Sheets AA1070 Used for Construction Description

Aluminum Sheets AA1070 is one semi-finished aluminium material.The Aluminum Sheets AA1070 is widly used in building, industry ect. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

Aluminum Sheets AA1070 Used for Construction is widely used for electronics, instruments, lighting decoration, packing industry, house decoration, curtain wall, honeycomb-core panel, sandwich panel, aluminum composite panel and aluminum composite pipes.

2.Main Features of Aluminum Sheets AA1070 Used for Construction

a.Competitive price---We have our own mills and can produce mill finished aluminium coils, so we can control the production cost better.

b.Professional after-sale service---We have more than 15 years exportation experience and you need not worry about the exporation problems.

c.Fast delivery time---We can control the delivery time within 35 days.

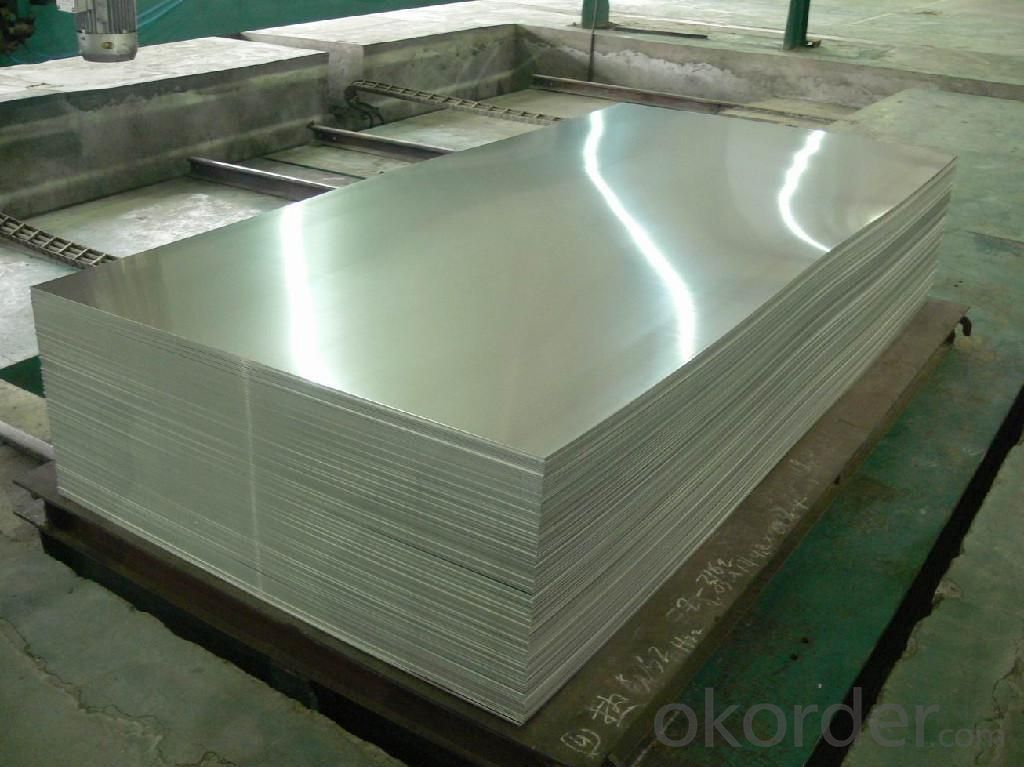

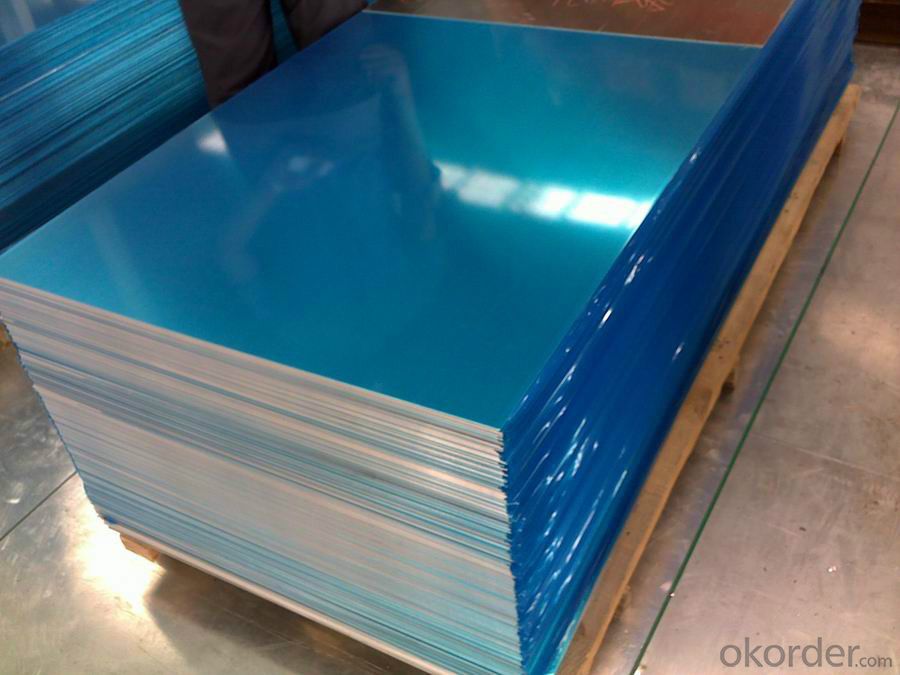

3.Aluminum Sheets AA1070 Used for Construction Images

4.Aluminum Sheets AA1070 Used for Construction Specification

Alloy | AA1070 |

Temper | H14, H16, H18, H22, H24, H26, H32, O/F |

Thickness | 0.2mm -- 100mm |

Width | 30mm -- 1700mm |

Standard | GB/T 3880-2006,EN,ASTM,JIS |

5. FAQ of Aluminum Sheets AA1070 Used for Construction

A.How to guarantee the quality?

Customers are welcome to our mill to visit and check the products. Besides, we can arrange a third party to test Aluminum Sheets AA1070 Used for Construction.

B.When will you deliver the products?

Aluminum Sheets AA1070 Used for Construction will be delivered within 35 days after receiving advanced payment or original L/C.

- Q:Can aluminum sheets be used for curtain walls?

- Certainly, curtain walls can utilize aluminum sheets. Aluminum proves to be a favored option for curtain wall systems because of its lightweight, enduring, and corrosion-resistant properties. Aluminum sheets can be effortlessly molded into different forms and dimensions, rendering them ideal for crafting the structural framework of curtain walls. Moreover, aluminum can undergo coating or anodization processes to enhance its visual appeal and offer extra safeguard against weather conditions. Consequently, aluminum sheets emerge as a versatile and pragmatic material for erecting curtain walls in both commercial and residential structures.

- Q:Can aluminum sheets be used for roofing?

- Indeed, roofing can be done using aluminum sheets. The preference for aluminum in roofing material selection is attributed to its sturdy composition, low weight, and resistance to rusting. Aluminum roofing sheets have gained recognition for their impressive lifespan, capable of enduring for many years without requiring replacement. Furthermore, aluminum possesses exceptional reflective capabilities, aiding in reducing energy expenses by maintaining a cooler temperature within the structure in hot weather. Furthermore, aluminum is effortless to install, rendering it an appealing option for roofing ventures. In summary, aluminum sheets are a dependable and pragmatic alternative for roofing purposes.

- Q:Are aluminum sheets suitable for insulation purposes?

- Yes, aluminum sheets are suitable for insulation purposes. Aluminum is a good conductor of heat, so it can effectively reflect and block thermal energy. Additionally, aluminum sheets are lightweight, corrosion-resistant, and easy to install, making them a popular choice for insulation applications.

- Q:Hi, I'm new here. Yoroshigu.I'm trying to make flash paper for magic tricks.To do that I have to make flash powder but in my location I can hardly find ingredients. Not to think about buying. Usually, I wait for a season and buy firecrackers. Then, I take the power and soak them into the paper and dry. This works but not so flash. Burned more likely.So, I wonder if I take aluminium oxide from aluminium oxide sandpaper and mix with powder from firecracker would produce a brighter flash than firecracker power alone?anyone know please share.

- Flash paper is not made with flash powder. Flash paper is paper that's been nitrated. The easiest way to make it is to get some nitrocellulose, pour it onto a sheet of glass or other flat surface, wait for it to dry and then scrape it off. It'll dry into a thin sheet that you can light and it'll burn just like flash paper. I do not suggest making flash powder. It's both friction and static sensitive and even a small unconfined amount can blow off your fingers. It's really not worth it.

- Q:Can aluminum sheets be used for protective barriers?

- Aluminum sheets are indeed suitable for protective barriers. Being both lightweight and durable, aluminum possesses exceptional strength and corrosion resistance. Its utilization is widespread across a multitude of contexts necessitating protection, such as construction sites, industrial facilities, and military installations. By effortlessly undergoing fabrication and shaping, aluminum sheets can be transformed into robust barriers that effectively impede unauthorized access and offer protection against potential hazards. Furthermore, aluminum demonstrates remarkable versatility as it can be combined with materials like glass or steel to heighten its protective capabilities. All in all, due to their strength, durability, and versatility, aluminum sheets represent a dependable choice for protective barriers.

- Q:Aluminum does not react with oxygen.Aluminum is a very unreactive metal.Aluminum forms a tough protective coating with oxygen.Aluminum tarnishes instead of corroding.If you could explain why it would be helpful!

- Aluminum forms a tough protective coating with oxygen. The coating of aluminum oxide is not porous enough to let further oxygen through it, so the aluminum underneath is protected from further corrosion.

- Q:after putting aluminum sheet into the area between magnet and iron products, could magnet attract iron again?

- magnet can attract iron if the aluminum sheet isn't too thick. Because aluminum can't cut off magnetic line of force, unless aluminum sheet's thickness surpass the range of magnetic attraction.

- Q:Bauxite ore contains aluminum oxide, which is decomposed using electricity to produce aluminum metal and oxygen. What mass of aluminum metal can be produced from 125 g of aluminum oxide?I'm really confused and I need help. Thanks.

- Aluminum Oxide is put together from aluminum and oxygen. A quick look at the periodic table tells you that Al has a +3 charge, while O has a -2 charge. Thus the formula must be Al2O3. Now, the atomic mass of Al is 26.982, and of O 15.999. This means that there is that many grams of each in one mole of each respective element. Thus the formula Mass of Al2O3 is 2(26.982)+3(15.999) = 101.961 g Al2O3. There are 2 mols of Al, so 2(26.982) = 53.964 g Al per the formula mass (53.964/101.961). Now that you have a ratio for the amount of Al in Al2O3, simply multiply it by the mass of aluminum oxide you have to get the mass of Aluminum out. Thusly: (53.964/101.961) x 125g = 66.157 g Al Ta-da!

- Q:What is the lifespan of the aluminum sheets?

- The lifespan of aluminum sheets can vary depending on several factors such as the quality of the aluminum, the environment in which they are used, and the level of maintenance they receive. However, aluminum sheets are known for their durability and longevity. On average, aluminum sheets can last anywhere from 20 to 30 years, but with proper care and maintenance, they can even exceed this lifespan. Regular cleaning, protection from harsh weather conditions, and avoiding exposure to corrosive substances can all contribute to extending the lifespan of aluminum sheets.

- Q:Are aluminum sheets suitable for automotive body framing?

- Yes, aluminum sheets are suitable for automotive body framing. Aluminum is lightweight, corrosion-resistant, and offers excellent strength-to-weight ratio, making it an ideal choice for reducing vehicle weight and improving fuel efficiency. It is commonly used in modern automotive manufacturing for body panels and frames, providing structural integrity while maintaining durability.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Aluminum Sheets AA1070 Used for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords