Aluminum Sheet Metal Ceiling for Decoration

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t

- Supply Capability:

- 50000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

1.Structure of Aluminum Sheet Metal Ceiling for Decoration Description:

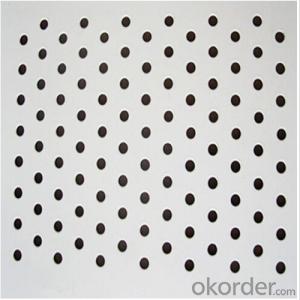

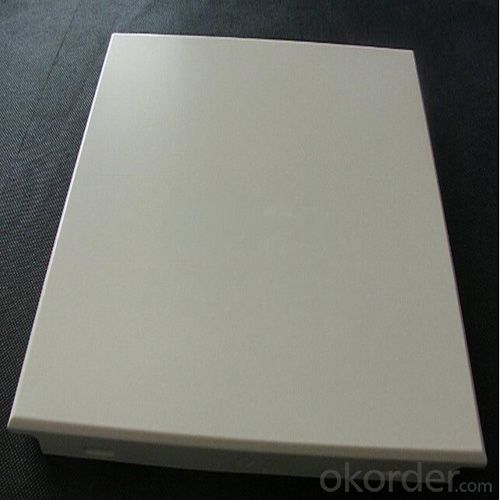

Aluminum Sheet Metal Ceiling for Decoration is in square ceiling, widest applicable among all type of ceiling with outstanding advantages. Plain or pattern can be selected according to the actual requirement. Clip in system which is concealed, steady structure, flat surface, could be both used as ceiling and wall panel.Perforation is a kind of processing technology for metal ceiling. ceiling design beautiful patterns according to the arrangement of perforated holes with powerful sound absorbing and isolating effect. We have over 40 kinds of fixed perforated types, and could be customized according to client's requirements on patterns, sound absorbing to meet the actual situation .

2.Main Features of Aluminum Sheet Metal Ceiling for Decoration:

1. Product Name: Aluminum False Ceiling

2. Color: Grey, RAL color available

3. Dimension: 600 x 600mm, custom made available

4. Surface finishing: Akzo Nobel powder coating

5. Material: aluminum alloy

3. Aluminum Sheet Metal Ceiling for Decoration Images:

4. Aluminum Sheet Metal Ceiling for Decoration Specification:

| Type | Type | Thickness | Surface Coating | Size | Color |

| Aluminum Perforated False Ceiling | Aluminum Alloy | 0.8mm, Custom made availabel | Akzo Nobel Electrostatic Powder Coating | 350 X 350, 350 X 700, 600 X 600, 600 X 1200, 618 X 618, Custom made availabel | White, Custom made available |

5.FAQ

Q1.How long have you been in this product?

A1:More than 10 years.

Q2. What's the minium quantity(MOQ)?

A2. 5 Metric tons

Q3. How long is shipping time?

A3. 7 (ready-made products)-25 days(OEM)

Q4. How do you guarantee the quality?

A4. 1. Cooperating and Exchaning experience with sevral quoted aluminum companies

2. Japanese and Swiss production line and skilled works (regular training and testing)

3. more than 10 years production experience.

Q5. Do you have after sale service?

A5. Yes. Any quality problem occurs within one year, pls take photoes,we will be responsible.

- Q:A copper-aluminum alloy has an aluminum concentration of (5.19x10^2) kg/m3.If the densities of aluminum and copper are 2.71 and 8.94 g/cm3, respectively, what is the concentration of aluminum in wt%?Could someone please help wit this question, im lost

- Copper Aluminum Alloy

- Q:Are the aluminum sheets suitable for manufacturing electronic enclosures?

- Indeed, aluminum sheets are well-suited for the production of electronic enclosures. The reason for aluminum's popularity in this regard lies in its remarkable combination of strength, durability, and lightness. Moreover, its capacity for conducting electricity effectively qualifies it for dissipating the heat generated by electronic components. Furthermore, aluminum sheets can be effortlessly molded, shaped, and machined to meet the precise specifications of electronic enclosures, thereby allowing for personalized and adaptable designs. Additionally, its ability to resist corrosion renders it suitable for safeguarding electronic devices against environmental elements. In summary, aluminum sheets offer the perfect material solution for the manufacturing of electronic enclosures.

- Q:It seemed in my experiment that aluminum wasn't reactive at all in the displacement reactions, except with copper sulfate. Is there a reason? or did I make a mistake? aluminum is more reactive than e.g silver nitrate, why didn't it react with it?

- Aluminium has a protective coating of Aluminium Oxide, this prevents many chemicals reaching the surface. This is because aluminium has a very strong affinity for oxygen and bonds to it with extremely strong bonds. It can be removed by dipping it carefully into a solution of Mercury (II) Chloride.

- Q:Can aluminum sheets be used for architectural cladding?

- Yes, aluminum sheets can be used for architectural cladding. Aluminum is a popular choice for cladding due to its durability, lightweight nature, and resistance to corrosion. It is commonly used in both residential and commercial buildings for its aesthetic appeal and versatility in various architectural designs.

- Q:What is the thickness range available for aluminum sheets?

- The thickness range available for aluminum sheets can vary depending on the specific requirements and applications. Generally, aluminum sheets can be found in a wide range of thicknesses, ranging from as thin as 0.006 inches (0.15mm) to as thick as 0.5 inches (12.7mm) or even thicker in some cases. However, it is important to note that the availability of specific thicknesses may vary depending on the supplier or manufacturer. Additionally, custom thicknesses can often be obtained through specialized fabrication processes.

- Q:Does Aluminum Foil really work to help beat the summer heat?I live in San Diego which is known for having perfect weather pretty much all year round, but just yesterday we are starting to get some record breaking heat. Most apartments, condos, and houses do not have A/C because like I just mentioned it's usually in the high 60s or low 70s during the spring and summer, perfect.Will Aluminum Foil work or can someone else suggest anything else?!PLEASE note that I'm just putting aluminum foil on my bedroom window which just faces some other apartment complex and I am not concerned with the aesthetics. I might consider putting something up (but just not sure what) on the living room window other than aluminum foil since everyone can see that window.

- First, get rid of the black curtain. Black absorbs solar heat, truthfully, any dark color. Put up white or a very light color instead. That will reflect the heat back out. You can buy an insulated pull shade or use automotive window tint on the window to help too. Another idea is to cover some foam board with foil and stick that in the window. And keep your bedroom door closed since you now have a window a/c unit. Good Luck!

- Q:How do you prevent galvanic corrosion when using aluminum sheets with other metals?

- To prevent galvanic corrosion when using aluminum sheets with other metals, there are several actions that can be taken: 1. Applying a protective coating, like paint or anodizing, on the aluminum surface can create a barrier between the aluminum and other metals. This prevents direct contact and reduces the risk of galvanic corrosion. 2. To isolate the metals and prevent galvanic corrosion, a non-conductive insulating material such as rubber or plastic can be placed between the aluminum and other metals. 3. Choosing metals that are less prone to galvanic corrosion when in contact with aluminum can reduce the risk. For instance, stainless steel, titanium, or other corrosion-resistant alloys are commonly preferred when working with aluminum sheets. 4. Inserting a dielectric material like nylon or Teflon washers between the aluminum and other metals can act as a barrier. This inhibits the flow of electrical current and prevents galvanic corrosion. 5. Controlling the environment by avoiding high moisture levels or extreme temperature variations can help in reducing the likelihood of galvanic corrosion. Proper ventilation and moisture control also play a significant role in preventing this type of corrosion. It's important to note that the most effective preventive measures may vary depending on the specific application and the types of metals involved. Seeking advice from a materials engineer or corrosion specialist can offer valuable guidance in selecting the most appropriate strategies to prevent galvanic corrosion in a particular scenario.

- Q:why is copper sheet but not aluminum sheet that becomes the negative pole after putting copper sheet and aluminum sheet connected with wire into concentrated nitric acid?

- According to metal reactivity series order table, aluminum has a better metallicity, but it will be passivated soon after contacting concentrated sulfuric acid, and won’t react again. But copper and concentrated sulfuric acid can react continually. So aluminum sheet becomes the positive pole after passivation.

- Q:Are aluminum sheets suitable for roofing systems?

- Yes, aluminum sheets are suitable for roofing systems. They are lightweight, durable, corrosion-resistant, and can withstand harsh weather conditions. Additionally, aluminum sheets have a long lifespan, require minimal maintenance, and are eco-friendly, making them a popular choice for roofing in many applications.

- Q:What is the typical fracture toughness of aluminum sheets?

- The typical fracture toughness of aluminum sheets can vary depending on the specific alloy and temper, but it is generally in the range of 20 to 35 MPa√m.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Aluminum Sheet Metal Ceiling for Decoration

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t

- Supply Capability:

- 50000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords