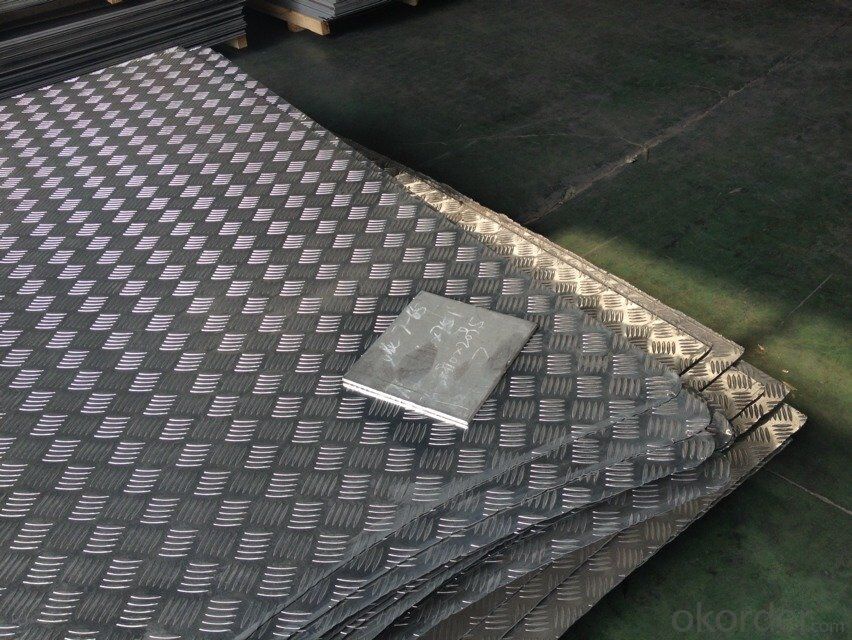

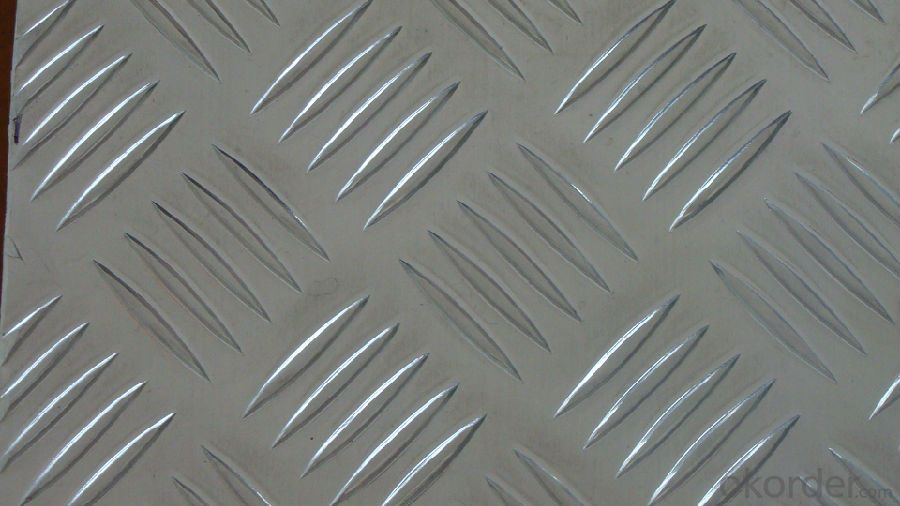

Aluminum Sheet Diamond Tread Plate Anti Skid Sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 8 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

aluminum chequered plate are widely usd for bus, cars and shipping vessel as the floor....

Aluminum tread plate is also called anti-slide aluminum sheet which is widely used in manufacturing vehicles, ships, washing machines, refrigerator shell, etc.

Specification:

Alloy: 1050, 1060, 1100, 3003, 3105, 5052

Temper: O, H12, H14, H16, H18, H22, H24, H26, H32

Thickness: 1.0~10mm

Width: 1000~1600mm

Length: 1000~6000mm

Packing:

One roll in an individual box or printed PP bag

Certain quantities in a standard carton

Depends on customer’s request

Service

1. We have the good and professional team, have a good after-sales service.

2. Accept any drawings or your samples to develop new product.

3. Offer relateive technical support,quick response,all your inquire will replied within 24 hours.

4. OEM, buyer design, buyer label services provided.

5. Have the certification of ISO 9001, SGS.

6. Special discount and protection of sales area provided to our distributor.

FAQ

Q1:Do you provide sample? How many days will samples be finished?

Free samples will be provided if needed, but customers should undertake shipping cost or freight charges, samples will be finished in 5-7days

Q2: Can we visit your factory?

Welcome to our factory at any time.

Q3: Complaint solving process

Finding your salesman—Salesman provide you the solution (If it’s our responsibility, we will resend substitutes or return money or provide discount for your next order, etc.; If it’s shipping company’s responsibility, we will also help you until the problem is resolved.) —If salesman can’t solve your problem, please call our manager .

Q4: Delivery time

3~30working days after confirming the payment. If the order is urgent, we will push our workers to finish in advance.

Q5: What's your MOQ?

Normally 8MT are requested as the minium order quantity ,we shall give

additional instructions in special circumstances.

Q6: What are the terms of payment and currencies do you accept?

T/T or L/C is accepted, currently we appreciated your payment through

USD,EUR, RMB

Q7: Do you accept customized orders?

Yes, we do. Your customized orders are always welcomed. Please kindly offer us your samples or drawings, so that we can customize the products according to your preferences. About any further detail, please feel free to contact us.

Q8: What information should I let you know if I want to get a quotation?

Your detailed requirements regarding the products's dimensions, including shape, thickness, top out (length*width*height), and your order quantity are highly appreciated if you want further information about our quotation

Q9: How about the mass production?

The lead time of mass production depend on quantity, usually 25-30days (20FT) .

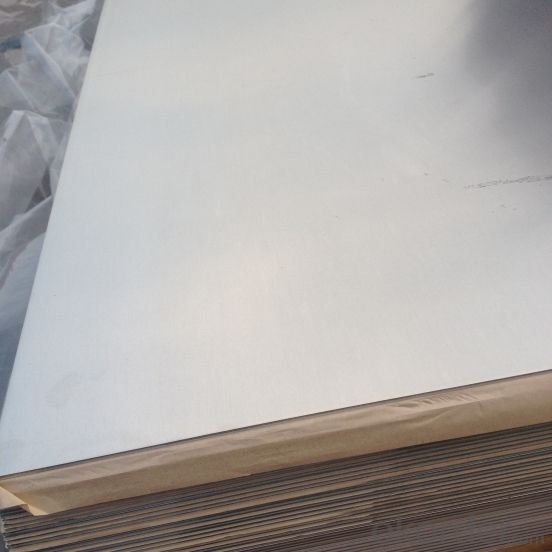

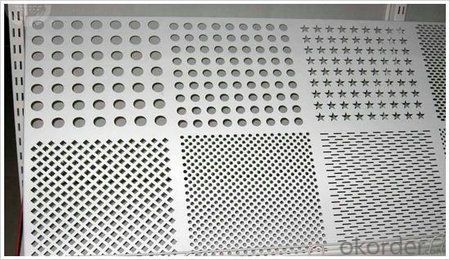

- Q:What are the different types of aluminum sheets?

- The different types of aluminum sheets include plain aluminum sheets, embossed aluminum sheets, perforated aluminum sheets, painted aluminum sheets, and brushed aluminum sheets.

- Q:Can aluminum sheets be used as a substitute for steel in certain applications?

- Yes, aluminum sheets can be used as a substitute for steel in certain applications. Aluminum is a lightweight and versatile material that offers several advantages over steel. It has a high strength-to-weight ratio, meaning it can provide the same strength as steel while being significantly lighter. This makes aluminum sheets an excellent choice for applications where weight reduction is critical, such as in aerospace, automotive, and transportation industries. Additionally, aluminum is highly resistant to corrosion, which eliminates the need for additional protective coatings or treatments. This property makes aluminum sheets suitable for applications in marine environments or other corrosive conditions. Aluminum sheets also exhibit excellent thermal conductivity, making them ideal for applications that require heat dissipation, such as heat exchangers or radiators. Furthermore, aluminum is more malleable than steel, allowing for easier shaping and forming. This characteristic makes aluminum sheets suitable for applications that require complex or intricate designs. However, it is important to note that aluminum has a lower tensile strength compared to steel. Therefore, in applications that require high load-bearing capacities or structural integrity, steel may still be the preferred choice. In such cases, a careful evaluation of the specific requirements and trade-offs between weight, strength, and cost should be considered before deciding on using aluminum sheets as a substitute for steel.

- Q:Can aluminum sheets be used for packaging purposes?

- Yes, aluminum sheets can be used for packaging purposes. They are commonly used in the packaging industry due to their lightweight, corrosion-resistant, and malleable properties. Aluminum sheets can be easily formed into various shapes and sizes, making them ideal for packaging products such as food, beverages, pharmaceuticals, and cosmetics. Additionally, aluminum provides a protective barrier against moisture, oxygen, and light, ensuring the quality and longevity of the packaged goods.

- Q:I get to do an aluminum blank for a fence and I am curious whether I can put slots in it with the router?I am not sure how thick it is, may say 3/16's.

- Yes you can use a router on aluminium. Use some kind of a fence, a piece of angle iron or a block of hardwood. Use a new bit, an old dull one will cause you problems. Pre-drill smaller holes than the slot width at each end of the slot. Stay back away from the end of the slot about 1/32 of an inch. Make several passes, at a depth of about 1/16 of an inch, per pass. If you can, make the slot with a bit smaller than the finished slot width. Use a 3/16 bit for a 1/4 inch slot. Use a 5/16 bit for a 3/8 inch slot. This will give cleaner slot edges and allow you to accurately make the slot width that you want. You can do this dry, but a little WD-40 oil will give even cleaner slot edges. Also climb mill the last pass on each slot edge to give a better/ smother edge. Climb Milling is pushing the router backwards of the way you normally travel in wood. Ben

- Q:What are the different methods for finishing the edges of aluminum sheets?

- Depending on the desired outcome and application, there are several approaches to finishing the edges of aluminum sheets. One commonly used method is edge trimming, where excess material is removed from the sheet's edges to achieve a smooth and straight edge. This can be accomplished using various tools like shears, saws, or routers. Another technique is edge deburring, which is employed to eliminate any sharp or rough edges left after cutting. Sanding or grinding tools are often utilized to smooth out the edges and produce a more polished finish. Moreover, edge rolling is a method that can be employed to create rolled or rounded edges on aluminum sheets. This is achieved by using a rolling machine that applies pressure to the edges, bending them into the desired shape. For a more decorative finish, edge profiling can be employed. This involves using specialized tools or machines to craft custom edge shapes or designs on the aluminum sheet. It allows for unique and aesthetically pleasing edges that enhance the overall appearance of the sheet. Lastly, edge painting or coating is an option worth considering. This process entails applying a protective or decorative paint or coating to the edges of the aluminum sheet. This not only provides a finished look but also helps protect the edges from corrosion or other damage. Ultimately, the choice of method for finishing the edges of aluminum sheets depends on factors such as the intended use, desired appearance, and specific project requirements.

- Q:Cooks are warned not to use aluminum cookware when preparing acidic foods. Why?

- The reacton will make the food taste bad..metalic. Aluminun will poisen your body. We should never use alluminum cookware.

- Q:If one were to hit someone with a baseball bat, would it cause more pain to use a wooden bat or an aluminum one? Just wondering.

- They both hurt a lot! Wooden ones are heavier and have more density, while aluminum ones are lighter, but they can swing a lot faster. So really, they both have their things about them that make them very painful. I wouldn't recommend getting smacked with ANY baseball bat - they HURT!!!

- Q:What are the different types of alloys used for anodized aluminum sheets?

- Anodized aluminum sheets can be made using various types of alloys, each with its own unique characteristics and uses. Some commonly used alloys include: 1. Pure aluminum, found in 1000 series alloys, is highly resistant to corrosion. It is frequently employed in anodized aluminum sheets across different industries such as architecture, automotive, and aerospace. 2. The 5000 series alloys, which contain magnesium as the primary alloying element, offer increased strength and excellent weldability. These alloys are often chosen for anodized aluminum sheets in applications that require high strength and resistance to atmospheric corrosion. 3. The 6000 series alloys are renowned for their exceptional combination of strength, extrudability, and corrosion resistance. Among this series, the 6061 alloy is widely used for anodized aluminum sheets in structural components, marine applications, and consumer electronics. 4. The 7000 series alloys are famous for their extraordinary strength and are typically used in applications that demand high-performance materials. The most commonly utilized alloy in this series for anodized aluminum sheets is 7075, which finds extensive use in the aerospace and defense industries. 5. The 2000 series alloys are mainly employed when high strength and excellent fatigue resistance are needed. These alloys are commonly used in the aerospace industry for anodized aluminum sheets. It is crucial to consider the specific requirements of the application, including desired strength, corrosion resistance, and other mechanical properties, when selecting the appropriate alloy for anodized aluminum sheets.

- Q:I need some aluminum sheets for an art project. I'm not sure where to find such a thing, though. I've looked at Home Depot briefly and aluminum flashing is the closest thing I've found. Flashing comes in a roll and is just a bit too thin. I need flat sheets of aluminum that are somewhat stiff, but not more than, say, 1/4 thick. Are there any stores that sell such things? A larger sheet would be fine if I could either get it cut at the store or find some way to cut it to the size I want. How do you cut aluminum, anyway? Any suggestions are greatly appreciated!

- diamond plate (the shiny stuff used for platforms and steps on firetrucks) comes in large sheets and is smooth on one side. you can cut it with a circular saw using a fine tooth carbide blade. wear goggles because the chips fly everywhere and you don't want little sharp metal pieces in your eyes. i'm not sure where to buy it but you may have some luck at northern tool, harbor freight, or a welding supply store.

- Q:Can aluminum sheet be used for architectural applications?

- Yes, aluminum sheet can be used for architectural applications. It is a versatile material that offers durability, lightweight properties, and corrosion resistance, making it suitable for various architectural projects such as facades, roofing, window frames, and decorative elements. Additionally, aluminum can be easily formed, fabricated, and finished to meet specific design requirements, making it a popular choice in the construction industry.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Aluminum Sheet Diamond Tread Plate Anti Skid Sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 8 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords