Aluminum Sheet And Plate And Slab And Other Grades Tempers

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 7 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Product Description

Cold rolled and hot rolled and cold drawn and hot drawn aluminum sheet is widely used in the field of construction field and decoration field, etc.

There are many different grades, such as: 1000 series, 2000 series, 3000 series, 5052,5754,5083,6061,6063,8011, etc.

The temper is include H14, H22,O,FO,H24, H44,H112,H114,etc.

2. Main features of the product

a.Competitive price

b.Frist-Class Service.

c. Shortest service.

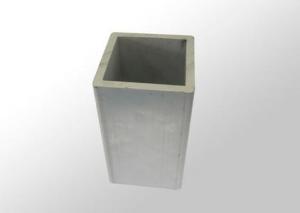

3. Image.

4. Product detailed sizes:

1000mm*2000mm, 1219mm*2438mm,1220mm*2440mm, 1000*1000,500*500,800*800,900*700mm,

1250mm*2500mm,1500mm*3000mm, etc.

5. FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006 or others.

What is the width range?

---It is from 1000mm to 2500mm, etc.

---Normally it is around 9000 tons totally.

Where is your client from?

---Normally it is from Japan, USA, ENGLISH, SINGAPORE, ETC.

What is your mainly products?

---Normally they are aluminum sheet, checkered sheet, mirror finish aluminium sheet, aluminum casting coil, etc.

- Q:What is the price of aluminum paint spray?

- It can also be calculated according to the weight. Do you have more aluminum profiles to be painted?

- Q:The aluminum and Fenglv aluminum material which is better suited for doors and windows

- Al Feng is one of the ten famous material, certainly no problem. But Feng packaging is too thick, high cost. To do the doors and windows of the aluminum used to choose cost-effective, as a special material for the sale of aluminum, I have the following recommendations: 1. The window wheel is good, and the pressed glass should be durable and corrosion resistant. 2. doors and windows sealing performance better, 3. pages to be matched with materials, gauze or rust, and thickness and density better than 4. The cost performance is high, the surface treatment layer of the profile is electrophoresis, and the electrophoresis layer should be thick. 5. The mounting frame needs to be hit to the horizontal line.

- Q:What are the different anodizing colors available for aluminum profiles?

- Aluminum profiles offer a variety of anodizing colors to choose from. These colors are obtained through a process known as anodization, which forms a protective oxide layer on the aluminum's surface. The most commonly used anodizing colors for aluminum profiles are clear, black, gold, bronze, and champagne. Clear anodizing is the natural color of aluminum and adds a transparent protective coating. It is often preferred for its ability to enhance the aluminum's appearance while maintaining its original color. Black anodizing is achieved by combining dyes and electrolytic processes. This color gives the aluminum profile a sleek and contemporary look, making it popular in architectural and decorative applications. Gold anodizing is achieved through a combination of dyes and electrolytic processes. This color adds a luxurious and elegant touch to the aluminum profile, making it an excellent choice for high-end applications like jewelry or luxury goods. Bronze anodizing is obtained by employing a combination of dyes and electrolytic processes. This color provides the aluminum profile with a warm and earthy tone, making it suitable for both modern and traditional designs. Champagne anodizing is achieved through a combination of dyes and electrolytic processes. This color imparts a light golden hue to the aluminum profile, giving it a sophisticated and timeless appearance. In addition to these standard colors, custom anodizing colors can be achieved by using different dye combinations or unique processes. These custom colors can be created to fulfill specific design requirements or to create a distinctive and attention-grabbing look.

- Q:Do aluminum profiles have good thermal insulation properties?

- Aluminum profiles, unfortunately, lack good thermal insulation properties. Due to its high conductivity, aluminum readily permits heat transfer. Consequently, when it comes to preventing heat transfer and providing thermal insulation, aluminum profiles are less efficient compared to materials like wood or vinyl. To improve the thermal insulation capabilities of aluminum profiles, they are frequently combined with thermal breaks or insulating materials. This combination serves to minimize heat loss or gain.

- Q:How do you ensure proper alignment and accuracy when using aluminum profiles?

- To achieve accurate alignment and precision when utilizing aluminum profiles, there are several crucial measures that can be implemented: 1. Opt for top-notch aluminum profiles that are manufactured with utmost precision and possess consistent dimensions. This will minimize profile variations and facilitate the attainment of accurate alignments. 2. Before commencing any assembly, meticulously cleanse the profile surfaces and any connecting elements like brackets or connectors. This will eliminate any dirt, dust, or debris that may hinder the alignment process. 3. Employ precise measuring tools such as rulers, calipers, or laser levels to meticulously measure and mark the intended positions for the profiles. This will guarantee correct alignment from the outset. 4. When connecting or joining multiple profiles, utilize alignment aids such as alignment pins or clamps. These aids will assist in holding the profiles in place while adjustments are carried out to achieve proper alignment. 5. Dedicate ample time to meticulously inspect and adjust the alignment at various points along the profile length. This will aid in identifying any inconsistencies or misalignments that may have occurred during the assembly process. 6. Prior to finalizing any connections or securing the profiles in place, thoroughly recheck all measurements and alignments. This will help prevent potential issues or errors that may arise later on. 7. If necessary, utilize shims or spacers to fine-tune the alignment. These minor adjustments can compensate for slight variations or inconsistencies in the profiles or installation surface. 8. Lastly, ensure that all connections and fasteners are securely tightened, without excessive force. Over-tightening can lead to misalignments or distortions, while loose connections can compromise the integrity and accuracy of the assembly. By diligently following these steps and paying meticulous attention to detail, it is possible to achieve proper alignment and precision when utilizing aluminum profiles. This will result in a robust and accurate structure that meets the desired specifications.

- Q:What are the different surface protection coatings for aluminum profiles?

- Some of the different surface protection coatings for aluminum profiles include anodizing, powder coating, painting, and electroplating. Anodizing forms a protective oxide layer on the surface, while powder coating and painting provide a durable and decorative finish. Electroplating involves depositing a thin layer of metal onto the surface to enhance its corrosion resistance.

- Q:Are aluminum profiles suitable for use in the marine industry?

- Aluminum profiles are indeed appropriate for utilization within the marine industry due to a multitude of reasons. Firstly, aluminum possesses numerous qualities that render it an exceptional material for marine applications. Primarily, aluminum exhibits a lightweight yet robust nature, which proves vital in the construction of boats and other marine vessels. Its lightweight composition enables enhanced speeds and superior fuel efficiency. Furthermore, aluminum showcases an impressive resistance to corrosion, thus making it an ideal candidate for enduring the harsh and corrosive marine environment. This particular attribute obviates the necessity for frequent maintenance and augments the lifespan of marine structures. Moreover, aluminum boasts exceptional thermal conductivity, facilitating prompt heat dissipation and diminishing the risk of overheating in marine engines. Lastly, aluminum is highly malleable and can be effortlessly molded into diverse shapes and profiles, granting versatility in both design and construction. In conclusion, employing aluminum profiles within the marine industry guarantees a combination of strength, durability, corrosion resistance, and lightweight properties, thereby establishing it as a suitable choice for marine applications.

- Q:Can aluminum profiles be used in display shelving and racking systems?

- Yes, aluminum profiles can definitely be used in display shelving and racking systems. Aluminum is a versatile and lightweight material that offers several advantages for these applications. Its strength-to-weight ratio makes it ideal for constructing sturdy and durable shelving and racking systems. Aluminum profiles can be easily customized and fabricated to meet specific design requirements, allowing for flexibility in creating different shelving configurations. Additionally, aluminum is corrosion-resistant, which is particularly beneficial in environments where moisture or chemicals may be present. The sleek and modern appearance of aluminum profiles also adds an aesthetic appeal to display shelving and racking systems. Overall, aluminum profiles are a popular choice for these applications due to their strength, versatility, and aesthetic qualities.

- Q:Can aluminum profiles be used for exhibition stands?

- Yes, aluminum profiles can be used for exhibition stands. Aluminum profiles are lightweight and versatile, making them an ideal choice for exhibition stands. They can be easily assembled and disassembled, allowing for easy transportation and storage. Additionally, aluminum profiles can be customized to fit the specific design and layout requirements of an exhibition stand. They can be used to create frames, partitions, and display panels, providing a sturdy and professional-looking structure. The use of aluminum profiles in exhibition stands also offers the flexibility to add accessories such as lighting fixtures, shelving, and signage, further enhancing the overall visual appeal and functionality of the stand.

- Q:Can aluminum profiles be used in the manufacturing of furniture?

- Yes, aluminum profiles can be used in the manufacturing of furniture. Aluminum is a versatile and lightweight material that offers several advantages for furniture production. It is highly durable, resistant to corrosion, and has a high strength-to-weight ratio. These properties make it suitable for various furniture applications, including chairs, tables, shelving units, and frames. Additionally, aluminum profiles can be easily customized, allowing for the creation of unique and modern designs. The use of aluminum in furniture manufacturing also contributes to sustainability, as it is a recyclable material. Overall, aluminum profiles provide designers and manufacturers with flexibility and durability, making them a popular choice in the furniture industry.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Aluminum Sheet And Plate And Slab And Other Grades Tempers

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 7 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords