Aluminum Sheet And Cold Rolled Plate Warehouse Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Product Description

Cold rolled aluminum sheet is widely used in the field of construction field and decoration field, etc.

There are many different grades, such as: 1000 series, 2000 series, 3000 series, 5052,5754,5083,6061,6063,8011, etc.

The temper is include H14, H22, H24, H44,H112,H114,etc.

2. Main features of the product

a.Competitive price

b.Frist-Class Service.

c. Shortest service.

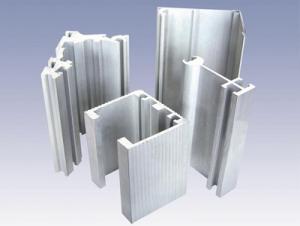

3. Image.

4. Product detailed sizes:

1000mm*2000mm, 1219mm*2438mm,1250mm*2500mm,1500mm*3000mm, etc.

5. FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006 or others.

What is the width range?

---It is from 1000mm to 2500mm, etc.

---Normally it is around 9000 tons totally.

Where is your client from?

---Normally it is from Japan, USA, ENGLISH, SINGAPORE, ETC.

What is your mainly products?

---Normally they are aluminum sheet, checkered sheet,

1100 grade and other else grades,

mirror finish aluminium sheet, aluminum casting coil, etc.

- Q:Are aluminum profiles suitable for medical equipment?

- Indeed, medical equipment finds aluminum profiles to be highly suitable. Aluminum, being a material that is both lightweight and strong, exhibits exceptional resistance to corrosion, thereby rendering it exceptionally appropriate for deployment in medical equipment. The ease with which aluminum can be transformed into diverse profiles and shapes further enhances its ability to meet specific demands. Moreover, aluminum possesses non-toxic, non-magnetic characteristics, and can be readily sterilized, thus rendering it completely safe for employment in medical settings. Furthermore, its capacity to withstand wear and tear, along with its durability, further amplifies its suitability for medical equipment, thereby ensuring extended and dependable functionality.

- Q:Are aluminum profiles suitable for indoor applications with high humidity?

- Yes, aluminum profiles are suitable for indoor applications with high humidity. Aluminum is highly resistant to corrosion and does not rust, making it an ideal material for humid environments. Additionally, aluminum profiles can withstand moisture and humidity without warping or deteriorating, ensuring their durability and suitability for such conditions.

- Q:Do aluminum profiles require any special maintenance?

- Yes, aluminum profiles require minimal maintenance. They are highly resistant to corrosion and rust, so regular cleaning with mild soap and water is usually sufficient. It is important to avoid using abrasive cleaners or tools that may scratch the surface. Additionally, lubricating moving parts with a silicone-based lubricant can help maintain their smooth operation. Overall, aluminum profiles are relatively low maintenance compared to other materials.

- Q:Many aluminum extrusions are edge banding materials. What special advantages do they have for opening materials?.

- Most brands have more openings. For example, New River aluminum material, the United States and aluminum, Zhong Wang aluminum and so on. Obviously, the sealing material has advantages. It's more popular now.

- Q:How do you prevent warping or distortion of aluminum profiles during fabrication?

- To prevent warping or distortion of aluminum profiles during fabrication, several measures can be taken. Firstly, it is important to ensure that the profiles are properly stored and handled before fabrication, avoiding any bending or twisting. During the fabrication process, maintaining consistent and controlled heat is crucial. This can be achieved through proper temperature regulation and using appropriate welding techniques. Additionally, employing fixtures or jigs to hold the profiles in place during fabrication can minimize any potential warping. Lastly, allowing sufficient cooling time after welding or machining processes can help alleviate any residual stress that may lead to warping.

- Q:What are the advantages of using aluminum profiles in the renewable energy sector?

- The utilization of aluminum profiles in the renewable energy sector brings forth numerous benefits. To begin with, these profiles possess a combination of lightness and strength, rendering them ideal for the construction of solar panel frames, wind turbine components, and other renewable energy infrastructure. Their favorable strength-to-weight ratio facilitates easy transportation and installation, thereby reducing costs and enhancing efficiency. Moreover, aluminum profiles exhibit exceptional resistance to corrosion, making them suitable for outdoor applications, even in harsh environments. This durability ensures the stability and functionality of renewable energy infrastructure over extended periods, including coastal areas and corrosive surroundings. Furthermore, aluminum profiles offer remarkable thermal conductivity, a crucial attribute for efficient heat dissipation in renewable energy systems. This property facilitates efficient cooling of solar panels, wind turbine generators, and other components, thereby improving their performance and lifespan. Additionally, aluminum is a sustainable material that can be effortlessly recycled. With the renewable energy sector's focus on promoting sustainability, the utilization of aluminum profiles aligns perfectly with the industry's objectives. Aluminum can be recycled repeatedly without compromising its properties, reducing the need for primary aluminum production and minimizing the carbon footprint of renewable energy projects. Lastly, aluminum profiles provide design flexibility and versatility. They can be easily customized and fabricated into various shapes and sizes, allowing for seamless integration into different renewable energy applications. This adaptability empowers engineers and designers to optimize the use of aluminum profiles, resulting in improved energy efficiency and overall system performance. In conclusion, the utilization of aluminum profiles in the renewable energy sector offers advantages such as lightweight strength, corrosion resistance, thermal conductivity, sustainability, and design flexibility. By incorporating aluminum profiles into renewable energy infrastructure, we can enhance the efficiency, durability, and environmental sustainability of the sector.

- Q:Can aluminum profiles be used in HVAC systems?

- Yes, aluminum profiles can be used in HVAC systems. They are commonly used for constructing ductwork, heat exchangers, and other components due to their lightweight, corrosion-resistant, and durable properties. Aluminum profiles are also easily customizable, making them suitable for various HVAC applications.

- Q:Can aluminum profiles be used for DIY projects or home improvement?

- Aluminum profiles have multiple applications in DIY projects and home improvement. Their versatility allows for easy cutting, shaping, and joining, enabling the creation of diverse structures and components. Despite being lightweight, they possess strength and durability, making them suitable for various projects. Whether you desire a personalized shelving unit, a garden fence, a solar panel frame, or even a one-of-a-kind furniture piece, aluminum profiles prove to be an excellent choice. Moreover, they possess corrosion resistance and require minimal upkeep, making them perfect for outdoor undertakings as well. With the appropriate tools and a touch of creativity, aluminum profiles can be transformed into functional and visually appealing additions to your home.

- Q:What are the anti-static properties of aluminum profiles?

- Due to their inherent electrical conductivity, aluminum profiles exhibit exceptional anti-static properties. This unique feature enables them to effectively dissipate static charges and prevent the build-up of static electricity. Consequently, aluminum profiles find widespread use in various industries, including electronics, automotive, aerospace, and manufacturing. In these sectors, they serve multiple purposes such as supporting conveyor systems, providing protective enclosures, and serving as grounding components. By minimizing the dangers associated with static electricity, such as electrostatic discharge (ESD) damage, fire risks, and interference with delicate electronic devices, the anti-static qualities of aluminum profiles guarantee safe and dependable operations.

- Q:80 series insulation aluminum broken bridge 1.4 thick, one square kilogram, how many kilograms aluminum material?

- Each brand of profiles, aluminum weight is not the same, but within the unit area is about 8 kilograms, little difference

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Aluminum Sheet And Cold Rolled Plate Warehouse Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords