Aluminum Sandwich Panel with Wholesale Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Aluminum Sandwich Panel Description:

Aluminum Sandwich Panel is a structure made of three layers: low density core inserted in between two relatively thin skin layers. This sandwich setup allows to achieve excellent mechanical performance at minimal weight. The very high rigidity of a sandwich panel is achieved thanks to interaction of its components under flexural load applied to the panel: core takes the shear loads and creates a distance between the skins which take the in-plane stresses, one skin in tension, the other in compression. General information on sandwich panel structure, different sandwich core types available and the potential with respect to weight savings is available in the following reference.

2.Main Features of the Aluminum Sandwich Panel :

Superior weather, corrosion, pollutant resistance

Even coating, various colors

Fireproof, excellent heat and sound insulation

Superior impact resistance

Lightweight and easy to process

Easy to maintain, self-clean

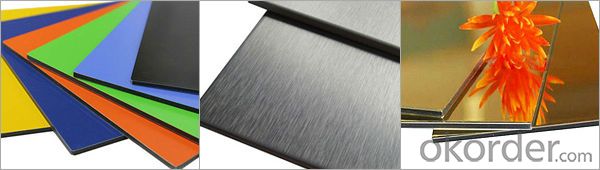

3. Aluminum Sandwich Panel Image:

| Our product image | ||

| ||

| PVDF aluminum composite panel | PE aluminum composite panel | Unbroken aluminum composite panel |

| ||

| Fireproof aluminum composite panel | Brushed aluminum composite panel | Mirror aluminum composite panel |

| Our factory |

|

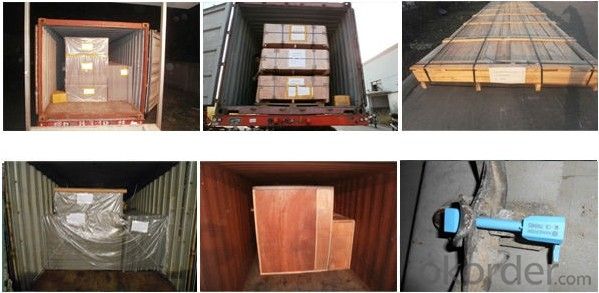

| Our package |

|

4. Aluminum Sandwich Panel Specification:

Width | 1000mm /1220mm /1250mm /1500mm /1550mm /1570mm |

Length | 2440mm /3200mm /4000mm /5000mm /6000mm(Max), or customized |

Thickness | 2mm / 3mm / 4mm / 5mm / 6mm (3mm and 4mm are most popular) |

Thickness of ALU-layer | 0.08mm,0.10mm,0.12mm,0.18mm,0.20mm,0.25mm,0.30mm,0.35mm,0.40mm,0.45mm,0.50mm |

Inner Core | Normal non toxic PE core, one side unbroken plastic, two side unbroken plastic, virgin LDPE, fireproof material |

Color | Solid color, metallic color, brush color, mirror, marble, wooden color, glossy |

Brand | OEM |

Surface | PE coating , PVDF coating, NANO, Brush surface, mirror surface |

Thickness of film | 0.07mm,0.09mm |

Packing | 1220*2440*4mm 1500 sheets in 1*20’ft container, nude packing; wooden pallet package for LCL. |

5.FAQ:

1) How about your quality?

According to international test standard, all the tested items are satisfied with high-class.

2).What are your certificates?

GB/T17748-1999 and ISO9001, SGS, CE etc.

3) How about your delivery time?

Within 15 working days after receiving deposite.

- Q:Aluminum plate is not assembled aluminum plate is not paste the clock

- Is not a series, the aluminum plate is veneer, aluminum-plastic plate is made of aluminum foil and plastic combination of integrated ceiling is one of the most bad material is not clear its series is 1 series and 3 series of aluminum

- Q:Whether the aluminum plate is non-combustible material

- Can provide non-combustible grade aluminum composite plate material, but can not say that aluminum-plastic plate is non-combustible material.

- Q:What is the cost of each material made by the bank's aluminum-plastic plate ceiling?

- Panjin domestic industry the best quality, large production of aluminum veneer. You say shape, but you do not have drawings, how to report the price to you.

- Q:Want to put the silicone plate into a right angle u line stick to a box outside, now do not know how to get that corner, will not use a wallpaper knife point it, cutting the kind of tool can use aluminum? Everyone who knows, tell me, thank you ah.

- You can cut the kind of aluminum-plastic plate tool, but the aluminum-plastic plate was 5mm Oh How thick is your silicone?

- Q:I want to open a small aluminum-plastic plate factory, how much money

- Production of aluminum-plastic board products, the need for pretreatment, painting, composite three sets of equipment, this down 800,000 on it, if it is a small factory, then you can find third-party manufacturers to paint, you can only on the composite line, so Single equipment 50 million enough.

- Q:OKorder Huayuan aluminum-plastic plate how?

- The company was the only company named "China Aluminum-plastic composite materials industry quality training base", in the organization of aluminum-plastic branch in this organization to carry out the quality of aluminum-plastic composite panel management, quality inspection, quality inspection and training to develop and modify the national standards activity.

- Q:Useful aluminum-plastic plate production line made of steel and aluminum did not?

- Use of aluminum-plastic plate production line made of steel and aluminum ??

- Q:What is the difference between aluminum and aluminum curtain wall aluminum veneer? That cost is high!

- Composite aluminum plate for the upper and lower layers of high purity aluminum alloy plate, the middle of non-toxic low-density polyethylene (PE) core board, also known as aluminum-plastic plate, aluminum veneer is a layer of aluminum. For the appearance of the difference between the two is not, but the color of aluminum-like pattern of some different. The price side of the curtain wall with the outer wall of aluminum-plastic board prices in 100 yuan, 2.5mm thick aluminum veneer prices around 240, 3mm veneer more expensive.

- Q:3MM aluminum composite panel prices

- The same structure of the 3 mm thick aluminum-plastic plate, according to different manufacturers and origin, the price is also very different, such as the production of Guangdong and Shandong production, Jiangsu and Zhejiang area production, the price difference is large, is the same product produced in Guangzhou, Then for 3 mm 0.12 mm aluminum thick product, the price is 80-180 yuan / Zhang between the bar.

- Q:Is there a good separation,

- Ethanol acetone heat treatment, stripping.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Aluminum Sandwich Panel with Wholesale Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords