Aluminum Profiles for Office Screen Office Partition

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

1. Specification of Aluminum Profiles for Office Screen Office Partition

Alloy | State | Tensile Strength δbMpa | Non-proportional Stretching Stress(δp0.2Mpa) | Stretching rate (δ%) | Pattern Thickness (mm) | HV | HW |

No Less Than | |||||||

6061 | T4/T6 | 180/265 | 110/245 | 16/8 | - | - | - |

6063 | T5/T6 | 160/205 | 110/180 | 8/8 | 0.8/- | 58/- | 8/- |

6063A | T5/T6 | 200,190/230,220 | 160,150/190,180 | 5,5/5,4 | 0.8,0.8/-,- | 65,65/-,- | 10,10/-,- |

2. Application of Aluminum Profiles for Office Screen Office Partition

wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors,windows…

3. Feature of Aluminum Profiles for Office Screen Office Partition

Surface Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Decoration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mochenical Property:

Chemical Composite and Mechanical Property

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

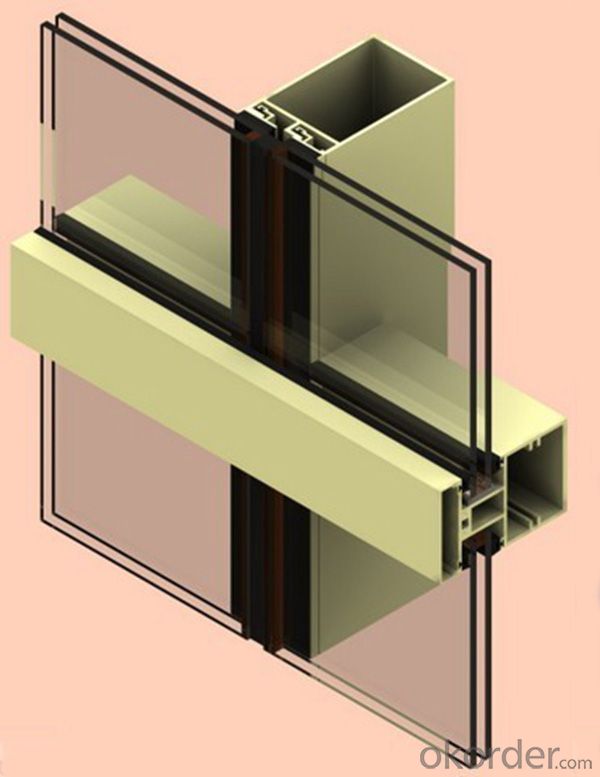

5. Image of Aluminum Profiles for Office Screen Office Partition

6. Package and shipping of Aluminum Profiles for Office Screen Office Partition

First, plastic cloth with drying agent inside; Second, Pearl Wool; Third, wooden cases with dry agent, fumigation wooden pallets, aluminum surface could cover blue PVC film

7. FAQ

Question 1: What is your MOQ?

We accept one ton per type for an order. But the detail we could negotiate.

Question 2: What is your normal terms of payment?

We always trade with you by T/T. But we also accept the L/C as you require.

Question 3: How many kinds of the surface treatment we can choose?

You could choose different color of powder coated. Anodized of black. matte silver, nature, champagne, bronze color. Mill finished. Wooden finished and printed.etc.

Question 4: Can you supply OEM services?

We offer OEM services for 17 years.

Question 5: How many days for opening the mould?

Normally about 10 days.According to the difficulty of your drawing.

Question 6: Can i choose the package what i want?

Yes, of course. We offer various kinds of package.e.g.PE foam. Shrink film. Wrapping paper.

But we would give you professional suggestion of package.

- Q:Can aluminum profiles be used in cleanroom environments?

- Yes, aluminum profiles can be used in cleanroom environments. Aluminum is a lightweight and versatile material that possesses many desirable qualities for cleanroom applications. It is non-corrosive, non-magnetic, and has a high strength-to-weight ratio, making it suitable for constructing cleanroom structures such as walls, partitions, and equipment racks. Aluminum profiles can be easily assembled and disassembled, allowing for flexible cleanroom configurations and future modifications. They can also be integrated with other materials like glass, acrylic, or stainless steel to meet specific cleanroom requirements. Additionally, aluminum profiles can be anodized or coated to enhance their cleanliness and resistance to contamination. Anodization provides a protective layer on the surface of the aluminum, making it more resistant to scratches and wear. Coatings such as epoxy or powder coatings can further improve the durability and cleanliness of the profiles. Overall, aluminum profiles offer numerous advantages for cleanroom applications, including their lightweight nature, strength, corrosion resistance, and flexibility in design.

- Q:Are aluminum profiles suitable for curtain walls and facades?

- Yes, aluminum profiles are highly suitable for curtain walls and facades. Aluminum is a lightweight, durable, and versatile material that offers numerous benefits for these applications. Firstly, aluminum profiles provide excellent strength and structural integrity, making them capable of withstanding various weather conditions, including wind loads and seismic forces. This makes them ideal for curtain walls and facades, where structural stability is essential. Additionally, aluminum is highly corrosion-resistant, which is crucial for exterior applications. It does not rust or deteriorate when exposed to moisture or other environmental factors, ensuring the longevity and durability of the curtain walls and facades. Furthermore, aluminum profiles offer design flexibility. They can be easily extruded into various shapes and sizes, allowing for the creation of unique and visually appealing curtain wall systems and facades. Aluminum also has a high strength-to-weight ratio, enabling the construction of large and expansive glazed areas while minimizing the overall weight of the structure. Aluminum profiles are also easy to install and maintain. They can be prefabricated and assembled off-site, reducing on-site construction time and costs. Additionally, aluminum requires minimal maintenance, typically only requiring occasional cleaning to maintain its appearance and functionality. Moreover, aluminum is a sustainable material. It is fully recyclable, meaning that it can be reused and repurposed at the end of its lifecycle, reducing waste and environmental impact. This aligns with the growing demand for eco-friendly and sustainable building practices. In conclusion, aluminum profiles are highly suitable for curtain walls and facades due to their strength, durability, corrosion resistance, design flexibility, ease of installation and maintenance, as well as their sustainability. They offer numerous advantages that make them a popular choice for architects, engineers, and building owners in these applications.

- Q:Do aluminum profiles have good thermal insulation properties?

- No, aluminum profiles do not have good thermal insulation properties.

- Q:Are aluminum profiles suitable for use in the mining industry?

- Yes, aluminum profiles are suitable for use in the mining industry. Aluminum is lightweight, corrosion-resistant, and durable, making it ideal for various applications in mining equipment and infrastructure. It offers strength and stability while being easy to transport and install. Additionally, aluminum profiles can withstand harsh environmental conditions and are resistant to chemicals commonly found in mining operations.

- Q:What are the dimensions and sizes of aluminum profiles?

- The dimensions and sizes of aluminum profiles can vary greatly depending on their intended use and design. They can range from small and narrow profiles, such as 10mm x 10mm square tubes, to larger and wider profiles, such as 100mm x 100mm square tubes. Additionally, aluminum profiles can come in various shapes, including square, rectangular, round, and custom shapes, to accommodate different applications and structural requirements. It is important to consult specific product catalogs or manufacturers for precise dimensions and sizes of aluminum profiles.

- Q:What are the different colors available for aluminum profiles?

- Design and aesthetics in aluminum profiles can be enhanced with a plethora of color options. Silver, black, bronze, and white are among the most commonly chosen colors. These colors are achieved through various finishing techniques like anodizing and powder coating. Anodizing involves the creation of a protective oxide layer on the aluminum surface, which can be dyed to achieve a range of colors. Conversely, powder coating entails the application of dry powder paint onto the aluminum, followed by heat curing, resulting in a resilient and vibrant finish. Moreover, specialized coatings and finishes enable the creation of custom colors. In summary, the wide array of color choices in aluminum profiles allows for versatility in architectural, industrial, and decorative applications.

- Q:How do you cut and shape aluminum profiles?

- To achieve the desired outcome and utilize the available tools, there are various methods for cutting and shaping aluminum profiles. Here, we present three commonly employed techniques: 1. Hacksaw or Miter Saw: This method is the most straightforward and accessible. By employing a hacksaw or a miter saw equipped with an aluminum cutting blade, you can mark the desired length on the profile and cautiously cut through it. It is crucial to maintain a secure grip on the profile and execute deliberate, unhurried cuts to prevent excessive vibration or the blade from getting stuck. 2. Power Saw or Circular Saw: When dealing with larger or thicker aluminum profiles, employing a power saw or circular saw equipped with a specialized aluminum cutting blade can expedite the process and make it more manageable. After measuring and marking the desired length on the profile, firmly secure it in place. Utilize the power saw to gradually and steadily cut through the profile, ensuring a firm grip and maintaining control throughout the procedure. 3. File or Grinder for Shaping: Once the profile is cut to the desired length, it may be necessary to shape or smooth the edges. This can be accomplished by utilizing a file or grinder equipped with an aluminum grinding wheel or sanding disc. Meticulously work the file or grinder along the edges, shaping or smoothing them as required. Be careful not to exert excessive pressure, as aluminum quickly heats up and may warp or sustain damage. When working with aluminum profiles, remember to wear appropriate safety gear, such as gloves and eye protection. Furthermore, it is advisable to practice on scrap pieces beforehand to familiarize yourself with the techniques and tools before commencing work on the final product.

- Q:How are aluminum profiles insulated?

- There are several methods available to enhance the thermal performance of aluminum profiles. One way is to incorporate a thermal break into the profile design. This involves inserting a non-conductive material, such as polyamide or polyurethane, between the inner and outer parts of the profile. By doing so, heat transfer between the interior and exterior of a building is minimized, resulting in improved energy efficiency. Another approach to insulating aluminum profiles is to apply insulating materials, such as foam or rubber, to either the interior or exterior surfaces of the profile. These materials act as barriers, reducing heat transfer and providing additional insulation. Additionally, insulating gaskets or seals can be fitted to aluminum profiles. These gaskets, typically made of rubber or other insulating materials, are positioned between the profile and the glazing. They create a thermal barrier, preventing heat loss or gain. In summary, the insulation of aluminum profiles can be achieved through the incorporation of thermal breaks, the application of insulating materials, or the use of gaskets. These methods effectively minimize heat transfer and enhance the energy efficiency of buildings.

- Q:Hangzhou aluminum how much money one meter, where can wholesale?

- Decoration materials market, your question is too general profile a variety of non-standard standard and non-standard decoration for many non-standard to open mold and MOQ is non-standard aluminum ingot processing fee plus 5000 yuan I hope to help you. Thank you!

- Q:What are the different types of extrusion processes used for aluminum profiles?

- There are several different types of extrusion processes used for manufacturing aluminum profiles. These processes are commonly used in the aluminum industry to create a wide range of shapes and sizes for various applications. 1. Direct Extrusion: This is the most common type of extrusion process used for aluminum profiles. In this process, a heated aluminum billet is forced through a die using a ram or screw, resulting in a continuous profile with a consistent cross-section. 2. Indirect Extrusion: Also known as backward extrusion, this process involves forcing the heated billet through a stationary die using a hollow ram. The ram pushes against the back of the billet, causing it to flow through the die and form the desired profile. 3. Hydrostatic Extrusion: Hydrostatic extrusion is a specialized process used for extruding aluminum profiles with complex shapes and thin walls. In this process, the billet is placed in a sealed container filled with a pressurized fluid, which helps to control the flow of the material and reduce the risk of defects. 4. Impact Extrusion: This process is used to create hollow profiles by striking a slug of aluminum with a punch while it is inside a die. The impact forces the material to flow around the punch and take the shape of the die, resulting in a seamless profile with excellent dimensional accuracy. 5. Cold Extrusion: Cold extrusion is a process used to manufacture aluminum profiles at room temperature. In this process, a billet is placed in a die and pressure is applied to force the material through the die, resulting in a profile with improved strength and surface finish. 6. Hot Extrusion: Hot extrusion is similar to direct extrusion, but the billet is heated to a higher temperature before being forced through the die. The elevated temperature helps to reduce the material's strength and increase its ductility, allowing for the creation of more complex profiles. Each of these extrusion processes has its advantages and limitations, and the choice of the process depends on factors such as the desired profile shape, size, complexity, and the specific requirements of the application.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Aluminum Profiles for Office Screen Office Partition

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords