Aluminum Profile Sunflowers For Heat Sink

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

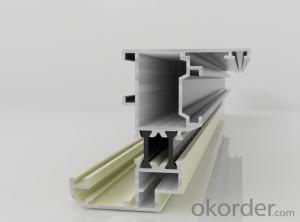

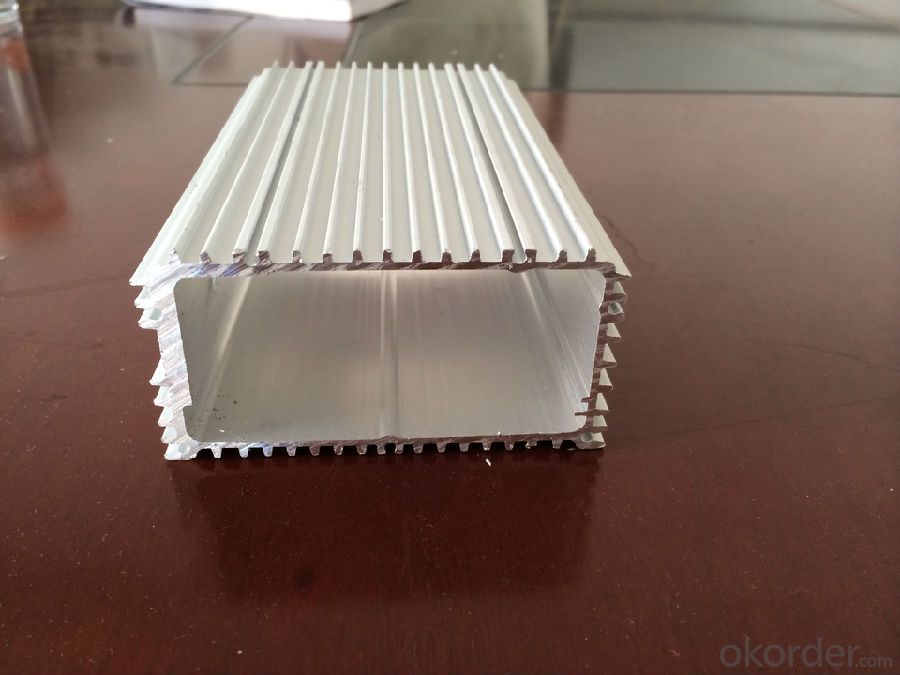

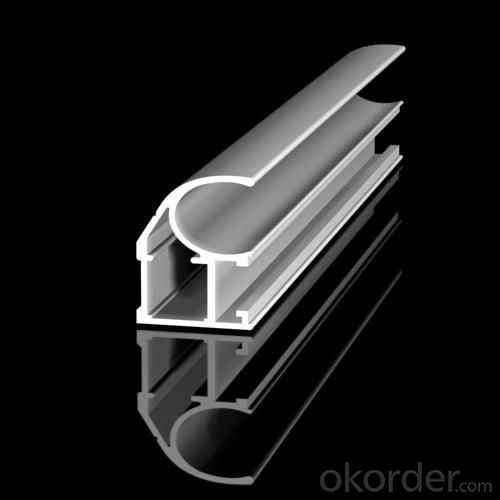

Structure of Aluminum Profile Sunflowers For Heat Sink Description:

We have more than 10 years experiences on manufacturing kinds of aluminum profiles, such as Aluminum Window & Door profiles, Aluminum tile trim profiles, Aluminum profiles for LED light, Round/Square General profiles, Aluminum heat sink, Aluminum heating insulation profiles, Curtain wall Aluminum profiles, and others Industry profiles.

Our products have exported to all over the world, and we also have a large of market share in Algeria, Angola, Philippine, Guinea, Ghana, South Africa, Nepal, Nigeria, Tanzania, Iraq etc.

Main Features of the Aluminum Profile Sunflowers For Heat Sink:

1, Strong R&G: help customers finalize the design, strong tool design ability, excellent, pressing and surface treatment technology;

2, Strong quality management: ISO&SGS SYSTEM;

3, 24 hours on-line communication, professional, patient, flexible;

4, High capacity of manufacturing and wide range of products;

5, We can provide secondary manufacturing.

6, High corrosion resistance, high weather resistance and good wear resistance.

7, Alternative surface treatment: Colorful ANODIZE, POWDER COATING, ELECTROPHORESIS & WOODEN GRAIN. Plentiful colors upon your needs.

8, Excellent material for smooth and subtle edges, elegant appearance.

9, Strong coated adhesion which is suitable for construction and industrial material.

Images of the Aluminum Profile Sunflowers For Heat Sink:

Aluminum Profile Sunflowers For Heat Sink Specification:

Material | Alloy Aluminum 6063,6061,6005 or customer nominated |

Temper | T3, T4, T5, T6 |

Surface | Anodize, electrophoresis, powder coating, PVDF coating, wood grain painting, matted, etc. |

Colour | Any colour based on Standard Germany RAL Mark |

Length | Coating 6.5 meters, Anodizing 6.5 meters, Mill finish 5 meters |

Press Machine | 500-4000 tons all together 64 press lines. |

Fabrication | 1. Windows and doors; 2. Drilling; 3. Bending; 4. Cutting; 5. etc. |

Certificate | ISO 9001 |

Moulding | 1. Using our moulds, no fee; |

2. Using customer drawing, opening mould, usually about 10~50 tons then the moulding can be refunded. | |

3. Mould cost is negotiable base on the order quantity | |

Capability | Annual output 100,000 tons |

FAQ:

1.Q: What about leadtime ?

A: Normally the leadtime is 60days after we receive the deposit and confirm the details. All the press machines we use is the best quality in China Yangli brand. The press machine leadtime from Yangli is 50days, the best leadtime we can give is 60days.

2.Q: What's the lead time for moulds?

A: Normally the mould leadtime is 45 days after we confirm all the details with customer. Our professional mechanical enginners from Austria will design the mould according to the samples from customer, or by the specifications offered by customers.

3.Q:What kinds of mould you can make? and what is your strong point for the moulds?

A: we can make wrinkle wall mould and smooth wall mould both. For wrinkle wall mould we can make, 79" pan, fish pan, bbq pan. For smooth wall mould we can make muffin cup, and cake cup, tar cup,etc. We can also make 2 or 3 portion conatiner moulds as long as you offer us sample or specifications. Our strong points are all our moulds are WEDMLS cut, which makes the mould more accurate and precise. Important materials likestainless steel parts we make in Austria. We also recut after heat treatment, which most of makers do not take this process.

- Q:Are aluminum profiles suitable for indoor applications with high humidity?

- Yes, aluminum profiles are suitable for indoor applications with high humidity. Aluminum is highly resistant to corrosion and does not rust, making it an ideal material for humid environments. Additionally, aluminum profiles can withstand moisture and humidity without warping or deteriorating, ensuring their durability and suitability for such conditions.

- Q:What are the different surface finishing options available for aluminum profiles?

- Aluminum profiles offer a range of surface finishing options, each with its own advantages and visual appeal. Some commonly used options include: 1. Anodizing: By creating a protective oxide layer through an electrochemical process, anodizing enhances corrosion resistance and provides various color choices. Anodized aluminum profiles are long-lasting, easy to maintain, and have a sleek, attractive look. 2. Powder Coating: This method involves applying dry powder to the aluminum profile's surface and then curing it with heat. The result is a durable, decorative finish that resists chipping, scratching, and fading. Powder coating offers a wide range of colors and can be customized for different textures and effects. 3. Polishing: Achieving a high-gloss, reflective appearance, polishing involves using abrasives and compounds to remove imperfections. This mechanical process creates a mirror-like finish, often used for decorative purposes where a shiny look is desired. 4. Brushing: By using abrasive brushes or pads, brushing creates a textured, brushed finish on the aluminum profile. This method produces parallel lines or circular patterns, providing a unique and stylish appearance. Brushed finishes are commonly used in architectural and interior design applications. 5. Electrophoretic Coating: Also known as e-coating, this immersion process involves applying an electrically charged paint to the aluminum profile. This ensures uniform coating thickness and excellent corrosion resistance. E-coating provides a smooth, even finish and is frequently used in automotive and industrial settings. 6. Wood Grain Effect: Aluminum profiles can be treated with a special coating to mimic the appearance of wood grain. This option is popular in architectural applications where the durability and low maintenance of aluminum are preferred over natural wood. These are just a few of the available surface finishing options for aluminum profiles. The choice of method depends on the desired appearance, functionality, and intended application of the profile.

- Q:Can aluminum profiles be cut to size?

- Yes, aluminum profiles can be cut to size. Aluminum profiles are typically manufactured in standard lengths and can be easily cut to the desired length or size using various cutting methods such as sawing, shearing, or CNC machining. This allows for customization and flexibility in using aluminum profiles for different applications.

- Q:Are aluminum profiles suitable for swimming pool enclosures?

- Swimming pool enclosures benefit greatly from the use of aluminum profiles. This material is not only durable and lightweight, but it also has a high resistance to rust and corrosion, making it perfect for humid and moist environments like swimming pools. Moreover, aluminum profiles can be easily customized to fit any pool size or shape, offering great versatility. In addition to this, they provide exceptional structural strength, ensuring the stability and longevity of the enclosure. Another advantage of using aluminum profiles is that they require minimal maintenance, resulting in cost-effectiveness. All in all, aluminum profiles are an excellent choice for protecting and enhancing the swimming pool area due to their durability, versatility, and low maintenance.

- Q:What are the standard dimensions and sizes of aluminum profiles?

- The standard dimensions and sizes of aluminum profiles can vary depending on the specific application and industry. However, there are some common dimensions and sizes that are widely used in various industries. In general, aluminum profiles come in various shapes such as angles, channels, tubes, and bars. The dimensions of these profiles typically range from small to large, with sizes measured in terms of width, height, and thickness. For example, aluminum angle profiles commonly have dimensions ranging from 1/2 inch to 8 inches in width and height, with thicknesses ranging from 1/16 inch to 1/2 inch. Aluminum channel profiles can have widths ranging from 1/2 inch to 12 inches, heights ranging from 1/2 inch to 3 inches, and thicknesses ranging from 1/16 inch to 1/4 inch. Aluminum tube profiles often come in various outer diameters, ranging from 1/8 inch to 6 inches, with wall thicknesses ranging from 1/32 inch to 1/4 inch. Aluminum bar profiles typically have widths ranging from 1/8 inch to 12 inches, heights ranging from 1/8 inch to 4 inches, and thicknesses ranging from 1/16 inch to 1/2 inch. It is important to note that these dimensions and sizes are just a general guideline, and specific applications may require custom dimensions or sizes. Additionally, different countries or regions may have their own standards and variations in aluminum profile dimensions and sizes. Therefore, it is always advisable to consult with manufacturers or suppliers to determine the specific dimensions and sizes that meet your requirements.

- Q:Can aluminum profiles be used for modular exhibition booths?

- Yes, aluminum profiles can be used for modular exhibition booths. Aluminum profiles are lightweight, durable, and easy to assemble, making them an ideal choice for creating modular exhibition booths. These profiles can be easily customized and reconfigured to meet specific booth design requirements. They offer a sleek and professional appearance and can be used to construct various elements of the booth, such as walls, frames, panels, and display shelves. Additionally, aluminum profiles can be easily transported and stored, making them a practical option for exhibition booths that need to be set up and dismantled multiple times.

- Q:How do aluminum profiles perform in fire-resistant structures?

- Aluminum profiles have proven to be highly effective in fire-resistant structures. Due to their inherent properties, aluminum profiles offer excellent fire resistance and are widely used in various applications where fire protection is crucial. One of the key benefits of aluminum profiles in fire-resistant structures is their ability to withstand high temperatures without compromising their structural integrity. Aluminum has a high melting point, around 660 degrees Celsius, which makes it highly resistant to heat. This property allows the profiles to maintain their shape and strength during a fire, ensuring the overall stability and safety of the structure. Furthermore, aluminum profiles have a low thermal conductivity, meaning they do not easily transfer heat. This characteristic helps to contain the spread of fire and limit its impact on the surrounding areas. By acting as a barrier against heat transfer, aluminum profiles can effectively compartmentalize the fire, preventing it from spreading rapidly and giving occupants more time to evacuate. In addition to their fire-resistant properties, aluminum profiles are also lightweight and durable. This makes them easy to handle during construction and reduces the overall weight of the structure. The durability of aluminum ensures that it can withstand the test of time, maintaining its fire-resistant properties for the lifespan of the structure. Moreover, aluminum profiles can be treated with special coatings or finishes to enhance their fire resistance. These coatings can provide an extra layer of protection, further delaying the ignition of the aluminum and improving its fire performance. Overall, aluminum profiles are highly reliable and efficient in fire-resistant structures. They offer exceptional fire resistance, containment of heat, and durability, making them a preferred choice for architects, engineers, and builders when designing structures that prioritize fire safety.

- Q:Can aluminum profiles be used for greenhouse construction?

- Yes, aluminum profiles can be used for greenhouse construction. Aluminum is a lightweight yet strong material that is resistant to corrosion, making it ideal for outdoor structures like greenhouses. It is also easy to work with, allowing for flexibility in design and construction. Additionally, aluminum profiles provide excellent thermal properties, which can help regulate temperature and improve energy efficiency within the greenhouse.

- Q:Are aluminum profiles suitable for electrical applications?

- Yes, aluminum profiles are suitable for electrical applications. Aluminum is a lightweight, durable, and corrosion-resistant material that can effectively dissipate heat, making it ideal for electrical components such as heat sinks, enclosures, and bus bars. Additionally, aluminum profiles can be easily customized and fabricated to meet specific electrical requirements.

- Q:What are the different surface engraving options for aluminum profiles?

- Aluminum profiles have several options available for surface engraving. Some of the most common techniques include: 1. Laser engraving: Achieving precise and clean results, laser engraving uses a high-powered laser to etch intricate patterns and fine details onto the aluminum profile. 2. Diamond drag engraving: Also known as diamond scratch engraving, this method scratches shallow grooves onto the surface of the aluminum profile using a diamond-tipped tool. It is suitable for creating logos, serial numbers, or simple designs. 3. Chemical etching: Custom designs, patterns, or textures can be created on the aluminum profile by using a chemical solution to selectively remove specific areas. 4. Mechanical engraving: A rotating cutting tool is used to engrave the aluminum profile in this method. It is commonly used for basic text or simple designs and can be performed manually or with the assistance of a CNC machine. 5. Sandblasting: By shooting a high-pressure stream of sand or other abrasive materials onto the surface of the aluminum profile, sandblasting creates a textured surface and achieves a matte or frosted finish. Each of these engraving options offers unique benefits and should be chosen based on the desired outcome, complexity of the design, and budget considerations. When selecting the most suitable engraving method for aluminum profiles, it is important to consider factors such as durability, precision, and aesthetic appeal.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Aluminum Profile Sunflowers For Heat Sink

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords