Aluminum Profile Sliding Windows and Doors Made in China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

1. Specification of Aluminum Profile Sliding Windows and Doors Made in China

Alloy | State | Tensile Strength δbMpa | Non-proportional Stretching Stress(δp0.2Mpa) | Stretching rate (δ%) | Pattern Thickness (mm) | HV | HW |

No Less Than | |||||||

6061 | T4/T6 | 180/265 | 110/245 | 16/8 | - | - | - |

6063 | T5/T6 | 160/205 | 110/180 | 8/8 | 0.8/- | 58/- | 8/- |

6063A | T5/T6 | 200,190/230,220 | 160,150/190,180 | 5,5/5,4 | 0.8,0.8/-,- | 65,65/-,- | 10,10/-,- |

2. Application of Aluminum Profile Sliding Windows and Doors Made in China

wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors,windows…

3. Feature of Aluminum Profile Sliding Windows and Doors Made in China

Surface Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Decoration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mochenical Property:

Chemical Composite and Mechanical Property

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

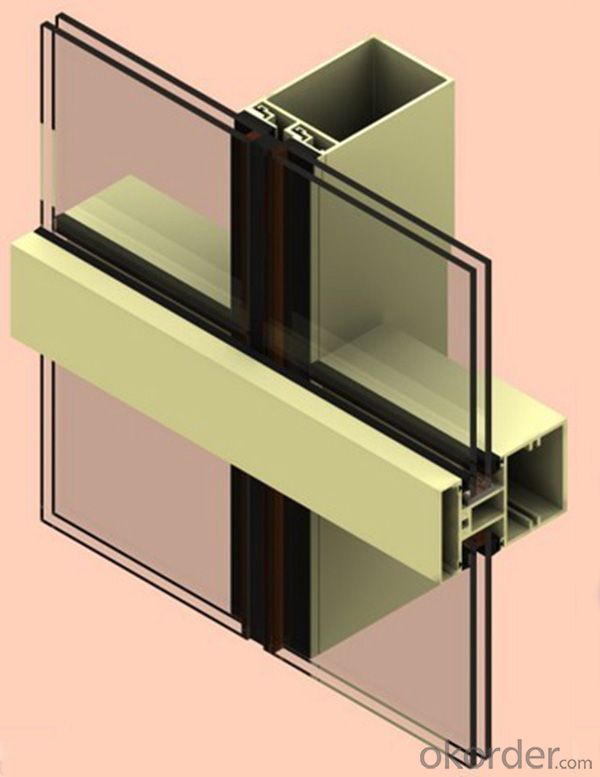

5. Image of Aluminum Profile Sliding Windows and Doors Made in China

6. Package and shipping of Aluminum Profile Sliding Windows and Doors Made in China

First, plastic cloth with drying agent inside; Second, Pearl Wool; Third, wooden cases with dry agent, fumigation wooden pallets, aluminum surface could cover blue PVC film

7. FAQ

Question 1: What is your MOQ?

We accept one ton per type for an order. But the detail we could negotiate.

Question 2: What is your normal terms of payment?

We always trade with you by T/T. But we also accept the L/C as you require.

Question 3: How many kinds of the surface treatment we can choose?

You could choose different color of powder coated. Anodized of black. matte silver, nature, champagne, bronze color. Mill finished. Wooden finished and printed.etc.

Question 4: Can you supply OEM services?

We offer OEM services for 17 years.

Question 5: How many days for opening the mould?

Normally about 10 days.According to the difficulty of your drawing.

Question 6: Can i choose the package what i want?

Yes, of course. We offer various kinds of package.e.g.PE foam. Shrink film. Wrapping paper.

But we would give you professional suggestion of package.

- Q:How about the weight calculation of 180 series semi concealed curtain wall aluminum profile

- A section of properties in CAD labeled dynamic block, the section area and mark block association graph can be easily calculated, section area, surface area, weight theory, and the setting up of a variety of materials such as aluminum options.

- Q:What are the factors involved in the selection of industrial aluminum profiles?

- Hardness: many customers are very concerned about the purchase of aluminum, and the preferred hardness is directly related to the chemical composition of the alloy. Secondly, the different states also have great influence. From the highest hardness, 7 lines, 2 lines, 4 lines, 6 lines, 5 lines, 3 lines, 1 lines are reduced in turn.Strength: strength is an important factor that must be taken into consideration when designing a product. As an aluminum alloy component, the appropriate alloy shall be selected according to the pressure to be taken. The strength of pure aluminum is the lowest, while the 2 and 7 series heat treatment alloys have the highest degree, and the hardness and strength have a certain lower phase relationship.

- Q:Are there any specific safety precautions when working with aluminum profiles?

- Working with aluminum profiles requires specific safety precautions that should be considered. Here are some important precautions to keep in mind: 1. Personal Protective Equipment (PPE): It is vital to wear appropriate PPE, such as safety glasses, gloves, and protective clothing, to safeguard against potential injuries. Aluminum chips or shavings can cause cuts or abrasions. 2. Ventilation: Ensure that the working area has proper ventilation to prevent the accumulation of aluminum dust or fumes. Aluminum dust can be combustible, and inhaling aluminum fumes can result in respiratory problems. 3. Fire Safety: Due to its high flammability, it is crucial to have fire prevention measures in place. Keep a fire extinguisher nearby and avoid sparks or open flames near aluminum profiles. Choose non-sparking tools and be cautious of excessive heat during cutting or welding processes. 4. Handling and Storage: Aluminum profiles can be heavy, so it is important to use correct lifting techniques to avoid back or muscle injuries. Store aluminum profiles securely and in an organized manner to minimize the risk of tripping or falling. 5. Cutting and Machining: When cutting or machining aluminum profiles, use appropriate tools and techniques. Ensure that the material is securely clamped before any cutting operation to prevent movement and potential accidents. 6. Ergonomics: Prioritize maintaining good ergonomics while working with aluminum profiles to reduce the risk of repetitive strain injuries or musculoskeletal disorders. Utilize ergonomic tools or equipment to minimize strain on the body. 7. Training and Knowledge: It is essential to undergo proper training and acquire knowledge about working with aluminum profiles. Understand the specific properties of aluminum and the associated hazards to work safely and efficiently. By adhering to these safety precautions, the risk of accidents, injuries, or health hazards when working with aluminum profiles can be significantly reduced.

- Q:Can aluminum profiles be used for exhibition stands or booths?

- Yes, aluminum profiles can be used for exhibition stands or booths. Aluminum is a versatile and lightweight material that is easy to handle and transport, making it ideal for creating modular structures. It offers durability, stability, and can be customized to fit various design requirements. Additionally, aluminum profiles can be easily assembled and disassembled, making them convenient for frequent use in exhibitions and events.

- Q:Can aluminum profiles be used for modular shelving systems?

- Yes, aluminum profiles can be effectively used for modular shelving systems. Aluminum is a lightweight yet strong material that offers excellent durability and resistance to corrosion. Its versatility makes it suitable for various applications, including shelving systems. Aluminum profiles can be easily customized and adapted to create modular shelving units of different sizes and configurations. Additionally, aluminum profiles can be easily assembled and disassembled, making them ideal for modular systems that can be adjusted or expanded as needed. Overall, aluminum profiles provide a reliable and aesthetically pleasing solution for modular shelving systems.

- Q:How do aluminum profiles contribute to LEED certification?

- LEED certification can be achieved through various means with the use of aluminum profiles. Firstly, aluminum is a sustainable material that can be easily recycled without compromising its quality. Incorporating aluminum profiles in construction projects helps reduce the demand for new raw materials, conserves energy, and minimizes greenhouse gas emissions. This aligns with LEED's objective of minimizing the environmental impact of buildings. Furthermore, aluminum profiles possess the qualities of being lightweight and durable, making transportation and installation efficient. This aspect contributes to earning LEED points in the Sustainable Sites category, which emphasizes the use of materials and techniques that have minimal impact on ecosystems and reduce pollution during construction. Moreover, aluminum profiles can enhance energy efficiency in buildings. By incorporating features like thermal breaks and insulation, aluminum profiles prevent heat transfer and reduce energy consumption for heating or cooling. This aspect contributes to earning LEED points in the Energy and Atmosphere category, which advocates for the use of energy-efficient systems and materials. Additionally, aluminum profiles are corrosion-resistant and require minimal maintenance throughout their lifespan. This durability contributes to earning LEED points in the Materials and Resources category, which encourages the use of long-lasting, low-maintenance materials to minimize waste and the need for replacement. In conclusion, aluminum profiles play a vital role in achieving LEED certification as they promote sustainability, reduce environmental impacts, improve energy efficiency, and enhance building durability. By considering the incorporation of aluminum profiles in construction projects, architects and builders can earn LEED credits and contribute to a more sustainable future.

- Q:What are the advantages of using aluminum profiles in the telecommunications infrastructure?

- There are several advantages to using aluminum profiles in the telecommunications infrastructure: 1. Lightweight: Aluminum profiles are significantly lighter than traditional materials like steel. This makes them easier to transport and install, reducing labor costs and time required for deployment. 2. Corrosion-resistant: Aluminum has excellent resistance to corrosion, meaning it can withstand harsh environmental conditions such as high humidity or exposure to chemicals. This makes it ideal for outdoor telecommunications infrastructure, where it may be exposed to the elements. 3. High strength-to-weight ratio: Despite its lightweight nature, aluminum profiles have a high strength-to-weight ratio. This means they can support heavy equipment and structures while still being relatively light, making them ideal for applications such as antenna mounts and support structures. 4. Easy customization: Aluminum profiles can be easily customized to meet specific design requirements. They can be cut, drilled, or shaped to fit unique specifications, allowing for flexibility in design and installation. 5. Cost-effective: Aluminum profiles are generally more cost-effective compared to other materials like steel or fiberglass. They require minimal maintenance, have a long lifespan, and can be recycled, reducing overall costs over the life cycle of the infrastructure. 6. Electrical conductivity: Aluminum is an excellent conductor of electricity, making it suitable for telecommunications infrastructure where electrical conductivity is required. 7. Aesthetically pleasing: Aluminum profiles have a sleek and modern appearance, which can enhance the overall aesthetics of the telecommunications infrastructure. This is particularly important in urban or residential areas where visual appeal is a consideration. Overall, the advantages of using aluminum profiles in telecommunications infrastructure include their lightweight nature, corrosion resistance, high strength-to-weight ratio, customization options, cost-effectiveness, electrical conductivity, and aesthetic appeal. These benefits make aluminum profiles a preferred choice for various components within the telecommunications industry.

- Q:Can aluminum profiles be used for curtain wall systems?

- Yes, aluminum profiles can be used for curtain wall systems. Aluminum is a popular material choice for curtain walls due to its lightweight, durability, and flexibility in design. It offers excellent structural integrity, weather resistance, and thermal performance, making it suitable for creating large glazed facades in buildings. Additionally, aluminum profiles can be easily fabricated, allowing for customization and integration of various components in curtain wall systems.

- Q:What is the difference between aluminum alloy and 6063-T5 6060-T66?

- 6060-T66, higher strength, average mechanical performance is higher than T6 under 20-30Mpa condition [T66 is in T6 (solid solution strengthening + fully artificial aging) condition, strengthened by special process status - in European standard can be found] 6063-T5 is the most common aluminum alloy and delivery condition, and most of the architectural profiles are applied

- Q:What are the different surface engraving options for aluminum profiles?

- There are several surface engraving options available for aluminum profiles. Some of the most common methods include: 1. Laser engraving: This technique uses a high-powered laser to etch the desired design or text onto the surface of the aluminum profile. Laser engraving provides precise and clean results, making it ideal for intricate patterns and fine details. 2. Diamond drag engraving: Also known as diamond scratch engraving, this method uses a diamond-tipped tool to scratch the surface of the aluminum profile. It creates shallow grooves that can be used to create logos, serial numbers, or other simple designs. 3. Chemical etching: Chemical etching involves using a chemical solution to remove specific areas of the aluminum profile. This process is often used to create custom designs, patterns, or textures on the surface of the profile. 4. Mechanical engraving: Mechanical engraving utilizes a rotating cutting tool to engrave the aluminum profile. This method is commonly used for basic text or simple designs and can be done manually or with the help of a CNC machine. 5. Sandblasting: Sandblasting involves shooting a high-pressure stream of sand or other abrasive materials onto the surface of the aluminum profile. This process creates a textured surface and can be used to achieve a matte or frosted finish. Each of these surface engraving options offers unique benefits and can be chosen based on the desired outcome, complexity of the design, and budget considerations. It is important to consider factors such as durability, precision, and aesthetic appeal when selecting the most suitable engraving method for aluminum profiles.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Aluminum Profile Sliding Windows and Doors Made in China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords