Aluminum Profile 6060 6061 6063 6082 Grade Aluminium Profile

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

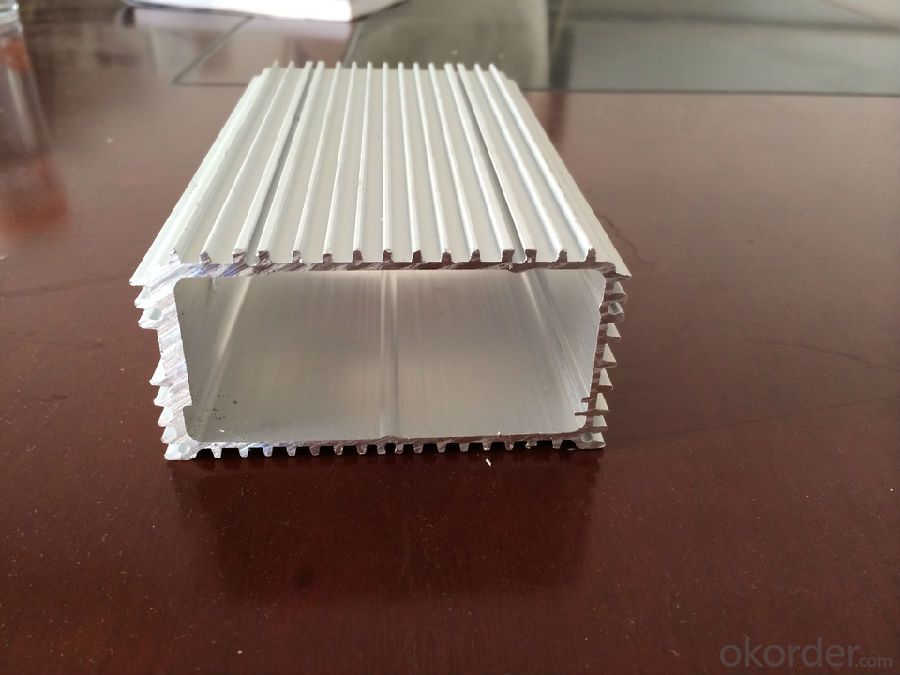

1.Structure of Aluminum Profile 6060 6061 6063 6082 Grade Aluminium ProfileDescription:

Aluminum Profile 6060 6061 6063 6082 Grade Aluminium Profile (also spelled anodising, particularly in the UK and Australia) is an electrolytic passivation process used to increase the thickness of the natural oxide layer on the surface of metal parts. Anodized aluminium surfaces, for example, are harder than aluminium but have low to moderate wear resistance that can be improved with increasing thickness or by applying suitable sealing substances.

2.Main Features of the Aluminum Profile 6060 6061 6063 6082 Grade Aluminium Profile:

High corrosion-resistance;

weather-resistance;

heat-resistance;

alkali-resistance and impact-resistance properties.

3.Aluminum Profile 6060 6061 6063 6082 Grade Aluminium Profile Images:

4.Aluminum Profile 6060 6061 6063 6082 Grade Aluminium Profile Specification:

1. Material: 6063,6061,6060,6005,6005A,etc.

2. Temper: T5 or T6

3. Finish: Mill finish, anodizing, powder coating, electrophoresis, wooden transfer or pvdf/carbon-flouride coated, polishing, brushing, sand blasting

4. Various colors: Silver, bronze, black, gold, blue, grey, champagne, bright, etc.

5. Machining: Cutting, punching, drilling, tapping, milling, bending, welding, CNC etc.

5.FAQ:

①How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China, consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe, America and Japan. OEM casting and forging service available according to customer’s requirements.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q:What are the potential fire hazards associated with aluminum coils?

- The potential fire hazards associated with aluminum coils include overheating, electrical failures, and the risk of flammable materials coming into contact with the coils.

- Q:What are the common cleaning and maintenance products for aluminum coils?

- Some common cleaning and maintenance products for aluminum coils include mild detergents, non-abrasive cleaners, and aluminum coil cleaners. Additionally, soft brushes or cloths can be used to remove dirt and debris from the coils. It is important to avoid harsh or abrasive cleaners that can damage the aluminum surface.

- Q:What is the expected lead time for manufacturing aluminum coils?

- The lead time for manufacturing aluminum coils can vary depending on several factors, such as the complexity of the coil design, the size and quantity of the coils being manufactured, the availability of raw materials, and the production capacity of the manufacturing facility. Generally, the lead time for aluminum coil manufacturing can range from a few weeks to several months. If the coils have a simple design and readily available raw materials, the lead time is usually shorter. However, if the coils have a complex design or require specialized materials, the lead time may be longer. Additionally, the production capacity of the manufacturing facility is a significant factor in determining the lead time. Facilities with higher production capacities can manufacture and deliver aluminum coils more quickly than those with lower capacities. To obtain an accurate estimate of the expected lead time, it is important to consult with the specific manufacturer. They will assess the project's specific requirements and provide a timeframe that aligns with those requirements.

- Q:Can aluminum coils be used for food processing equipment?

- Food processing equipment can indeed utilize aluminum coils. The reason behind the popularity of aluminum in this context lies in its remarkable thermal conductivity, resistance to corrosion, and lightweight properties. The food industry heavily relies on aluminum for a variety of applications, including heat exchangers, evaporators, and condensers. Specifically engineered to effectively transfer heat and uphold a consistent temperature, aluminum coils prove to be ideal for food processing equipment that demands precise temperature control. Moreover, aluminum is a non-toxic material, guaranteeing that it does not contaminate the processed food. Consequently, aluminum coils establish themselves as a dependable and secure choice for food processing equipment.

- Q:What are the common applications of aluminum coils in the aerospace industry?

- Aluminum coils are commonly used in the aerospace industry for various applications such as constructing aircraft frames, manufacturing wings, building fuselages, and designing engine components. The lightweight yet strong nature of aluminum makes it an ideal choice for these purposes, as it helps reduce overall aircraft weight, enhance fuel efficiency, and improve performance. Additionally, aluminum's corrosion resistance properties play a crucial role in ensuring the longevity and durability of aerospace structures.

- Q:Why do the layers loose when taking out coil after roll of aluminum 0.14?

- After rolling, the most possible reason may be poor deoiling effect. I think, for 0.14mm aluminum coil, the lining sleeve will not be forgotten. After rolling , oil ooze from aluminum layers, and the support of aluminum coil is not enough, leading to coil collapsing. The specific manifestations are that the edges of even round aluminum layers become like water ripple, and that the aluminum coils suddenly become uneven when taking out coil.

- Q:What are the potential challenges in recycling aluminum coils?

- Recycling aluminum coils presents several potential challenges that need to be addressed. To begin with, the removal of contaminants such as paint, oil, or other coatings from aluminum coils is a crucial step before the recycling process can commence. This task can be both time-consuming and costly as it requires thorough cleaning to ensure the quality of the recycled aluminum. Furthermore, the presence of mixed materials like steel or plastic in aluminum coils complicates the recycling process even further. These materials must be separated from the aluminum before it can be melted down and recycled. This separation necessitates specialized equipment and expertise, thereby increasing the cost and complexity of recycling aluminum coils. Transportation and logistics also pose a significant challenge in recycling aluminum coils. Their large and heavy nature makes it challenging and expensive to transport them to recycling facilities. Additionally, these facilities must possess suitable infrastructure to handle and process the coils efficiently. Moreover, the fluctuating market prices of aluminum contribute to the challenges in recycling aluminum coils. The value of recycled aluminum is influenced by global supply and demand, which can vary greatly over time. This unpredictability makes it difficult for recyclers to accurately predict the financial returns from recycling aluminum coils, potentially impacting the viability of the recycling process. Lastly, the overall awareness and participation in aluminum coil recycling present a challenge. Many industries and individuals may lack awareness regarding the benefits of recycling aluminum coils or may not have access to recycling facilities. Overcoming this challenge requires increasing education and improving accessibility to recycling programs, thereby promoting the sustainable recycling of aluminum coils.

- Q:Some properties of aluminum are summarized in the following list.normal melting point 658°C heat of fusion 3.95 kJ/g normal boiling point 2467°C heat of vaporization 10.52 kJ/g specific heat of the solid 0.902 J/g°C Calculate the quantity of energy required to heat 1.58 mol of aluminum from 33°C to its normal melting point? In KJCalculate the quantity of energy required to melt 1.02 mol of aluminum at 658°C? In KJCalculate the amount of energy required to vaporize 1.02 mol of aluminum at 2467°C? In KJ

- Calculate the quantity of energy required to heat 1.58 mol of aluminum from 33°C to its normal melting point in KJ- 1.58 mol x 26.98 g/mol x 0.902 J/g°C x (658 - 33)°C x 1 kJ/1000 J = 24.03 kJ Calculate the quantity of energy required to melt 1.02 mol of aluminum at 658°C In KJ- 1.02 mol x 26.98 g/mol x 3.95 kJ/g = 108.7 kJ Calculate the amount of energy required to vaporize 1.02 mol of aluminum at 2467°C In KJ- 1.02 mol x 26.98 g/mol x 10.52 kJ/g = 289.5 kJ

- Q:i came across marine grade aluminum (grade 6082), somebody was telling it is a special grade, i checked in internet, there is nothing specific in marine grade 6082, every manufacturer can produce it. please clarify. thanks

- This Site Might Help You. RE: what is marine grade aluminum? i came across marine grade aluminum (grade 6082), somebody was telling it is a special grade, i checked in internet, there is nothing specific in marine grade 6082, every manufacturer can produce it. please clarify. thanks

- Q:Tossing away an aluminum can wastes as much energy as pouring out half of that can’s volume of gasoline.what does that mean?

- There are two actions going on here. Throwing away a can and pouring out gasoline. Both are examples of wasting energy and the writer was trying to put a visual to the comparison. Since cans come in various sizes, the amount of energy is relative to the size of the can. For example, throwing out a 12 oz can is the same as pouring out 6 oz of gas.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Aluminum Profile 6060 6061 6063 6082 Grade Aluminium Profile

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords