Aluminum Polyester Film Lamination Foil and Copper Foil for Cable

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 kg

- Supply Capability:

- 1000000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

AL Pet Lamination Foil and Copper Lamination Foil for Cable Foil

1.Structure of Aluminum Mylar foil Shielding Foil Description:

Electrical cable is used to transfer electricity, information and the realization of electromagnetic energy transformation. The electrical cable in a broad term mainly indicates to cable and in a narrow term indicate insulation material. Its definition is the aggregation of different parts below: one or more insulation cores, the wrapping layers of the cores, the general protective layers and the outer protective layers. Cables also include additive conductor without insulator.

2.Main Features of the Aluminum Mylar foil Shielding Foil:

Aluminum Mylar foil Shielding Foil is applicable to the shielding of coaxial cable, local network wire, electronic communication cable and computer peripheral wire etc.

1.Thickness: min 6.5mic; width: 300-1000mm.

2. According to GB/T 3198-2010.

3.Usages: cable shield, candy wrap

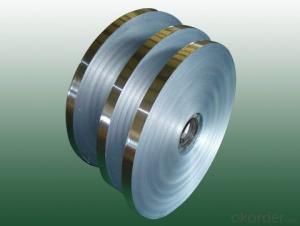

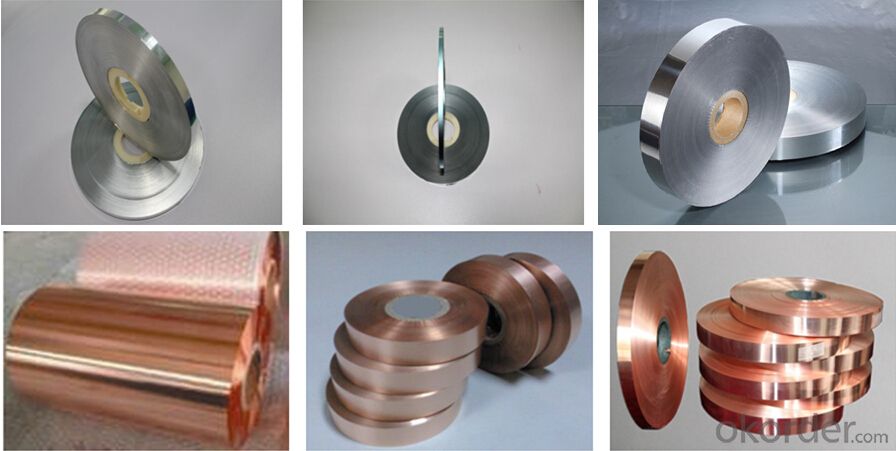

3. Aluminum Mylar foil Shielding Foil Images

4. Aluminum Mylar foil Shielding Foil Specification

AL-PET laminated foil

Description: Apply for overall or individual twisted pair shield for electronic cable and local network cables, protect from external electromagnetic interference. Features option of LUBRITAPE apply to decrease 50% friction of aluminum surface.

Construction: Aluminum foil, Polyester film

CODE | TOTAL THICKNESS | ALU THICKNESS | GLUE | POLYESTER FILM | WEIGHT |

FP007012 | 22±3 | 7 | 3 | 12 | 38.8±5% |

FP010012 | 25±3 | 10 | 3 | 12 | 46.9±5% |

FP020020 | 43±3 | 20 | 3 | 20 | 83.8±5% |

FP025012 | 40±3 | 25 | 3 | 12 | 87.6±5% |

Special specifications are also available, according to customer’s order. | |||||

AL-PET-AL laminated foil

Description: resilient shielding in cable assembling and provide the enhanced shielding required in harsh environments.

Construction: Aluminum foil +Polyester film+ Aluminum foil

CODE | TOTAL THICKNESS | ALU THICKNESS | GLUE | POLYESTER FILM | GLUE | ALU THICKNESS | WEIGHT |

DFP007015 | 35±3 | 7 | 3 | 15 | 3 | 7 | 65±5% |

DFP009020 | 39±4 | 9 | 3 | 15 | 3 | 9 | 76±5% |

DFP015025 | 61±5 | 15 | 3 | 25 | 3 | 15 | 115±5% |

DFP025025 | 80±5 | 25 | 3 | 25 | 3 | 25 | 175±5% |

Special specifications are also available, according to customer’s order. | |||||||

Bonded AL-PET laminated foil

Description: A laminated aluminum-polyester-aluminum tape is fully bonded to the foam dielectric to provide 100% coverage, longitudinally applied over the polyethylene core and the tape minimizes signal leakage.

Construction: Aluminum foil + Polyester film + Aluminum foil + EMAA film

CODE | TOTAL THICKNESS | ALU THICKNESS | GLUE | POLYESTER FILM | GLUE | ALU THICKNESS | GLUE | EMAA | WEIGHT |

DFPH009012 | 65±5 | 9 | 3 | 12 | 3 | 9 | 3 | 25 | 98±5% |

DFPH009020 | 72±5 | 9 | 3 | 20 | 3 | 9 | 3 | 25 | 108±5% |

DFPH009025 | 75±5 | 9 | 3 | 25 | 3 | 9 | 3 | 25 | 114±5% |

DFPH010025 | 84±5 | 10 | 3 | 25 | 3 | 10 | 3 | 25 | 126±5% |

Special specifications are also available, according to customer’s order. | |||||||||

Copper polyester foil

Description: Copper foil, copper lamination foil typically use as shielding for low/medium voltage cable and radio frequency coaxial cable. The rolled annealing copper foil is flexible to wrap cable core, also it has the excellent physical properties, Polyester film provides electrical insulation and high mechanical properties.

Construction: Copper foil + Polyester film

CODE | TOTAL THICKNESS | CU THICKNESS | GLUE | POLYESTER FILM | WEIGHT |

CP018012 | 33±3 | 18 | 3 | 12 | 175±10% |

CP007020 | 46±3 | 18 | 3 | 25 | 195±10% |

CP015012 | 30±3 | 15 | 3 | 12 | 160±10% |

Special specifications are also available, according to customer’s order. | |||||

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

① Where you used this foil?

Aluminum Mylar foil Shielding Foil is used for cable shield, candy wrap for the shielding of coaxial cable, local network wire, electronic communication cable and computer peripheral wire etc.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

- Q:It leaves this gross green satin on my fingerI wear it almost 24/7, its an antique.is that why? Help me!Thanks in advance.

- just use a turkey paster there basically the same thing and its long enough to get it all the way up there

- Q:is aluminum foil a pure substance?

- describe the situation that you think you will encounter first( should post this question on 'Bears' site)

- Q:I was always told to never leave food in a can, but not exactly whyCould I wrap it in Aluminum Foil?

- Eleven hours isn't bad.it is on the low end for his age.but my son is no different (aside from the restless)My son will fall asleep between 9:00 and 10:00 at night, will be up around 7:00am to nurse, then back to sleep until around 8:00.so he gets about eleven hours at night toohe'll sleep anywhere from 30minutes to two hours during the daySo, some days he's only getting around eleven and a half hours of sleep12-14 is the average for this ageAs far as the waking and shaking and screaming.have you looked into night terrors? My nephew had them for a while and it sounds a lot like itthere isn't much you can do to stop it, I'd go back to what was helping him before and see if he can work through thisIt takes time with kids, and if he's been hitting a lot of milestones these past four months, it could be attributing to the restless sleepGood luck!!

- Q:i would like to make a silencer for a ruger 10/22

- over at charlies but we finaly figured it out wasnt no good he got arrested been poachin at nite all smug and such then in court we seen the signlanguage lady telling the judge for charley that he had signed that , he wrote for plans to, they came rolled up, so he put them on end of that 06 and went huntin thensigned that he never heard a thing,,and wonderded how they knew, he was down in the grave yard shootin deer as every body there was dead already,

- Q:Back in nov, I split up a package of ground beef, wrapped each portion with aluminum foil, put in a ziplock bag and put in freezerThe beef was fresh when I did soToday when I took it out and unwrapped, the outside of the meat had turned brownIs it safe for me to cook and eat?

- He may grow out of itMany Siamese or similar types have that habitYou can put a little Bitter Apple Spray on the things he's sucking onHow old is he now and is he neutered?

- Q:I used to hit some pretty nice shots with my bat, then i went to the batting cages, and then i got dimple ball marks all over, so i went home, and tried to get rid of them, by using car polish ( or something like that) the next day i went to go hit against some live pitching, i kept on grounding everything right into the ground, Do you think the polish made everything slip right off the bat? or was it just me,? and if it was the bat, how do I make it less slipery

- The best fiber supplement is to eat lots of fruits and vegetables every day.

- Q:I have tried sandpaper and all it does is scrape up the paint a bitI was thinking a grinder would do the trick but I am not sure which type of grit would work for thatAlso I was thinking about chemically removing the paint as well.

- You might have hypothyroidismGet a checkup by a doctor.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Aluminum Polyester Film Lamination Foil and Copper Foil for Cable

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 kg

- Supply Capability:

- 1000000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords