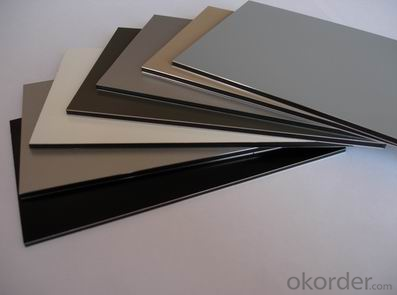

ALUMINUM PE COMPOSITE PANEL ORIGINAL CORLOR

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 6000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

1. Breif details

Place of Origin: Zhejiang, China (Mainland)

Brand Name: Jinxiang

Model Number: JX 6001

Usage: Outdoor

Function: Anti-Static, Antibacterial, Fireproof

Surface Treatment: Anodized, Brushed, Foil Decoration, Mirror, PE Coated, Printing, PVDF Coated, Nano Coated

Panel thickness: 2mm/3mm/4mm/5mm/6mm

Aluminum thickness: 0.10mm/0.12mm/0.15mm/0.21mm/0.30mm/0.40mm/0.50mm

Width: 1220mm,1250mm,1500mm,1570mm

Coating: PE, PVDF,NANO

Color: over 300 kinds of color (as per customer's requirement)

Core: Breakable,Unbreakable,Fireproof

Length: 2440mm (according to customers' request)

Standard size: 1220x2440mm

Logo: OEM (customer's logo and brand are welcome)

Name: Aluminium Composite Panel

2. Main Feature

. Excellent fireproof characteristics

Super peeling strength

Perfect cold resistance performance

Excellent surface flatness and smoothness

Superior weather, corrosion, pollutant resistance

Even coating, various colors

Superior impact resistance

Lightweight, easy to process and installation

Easy to maintain

3.Main Specification

PE/PVDF coated Aluminium Composite Panel Specification:

| Width(mm) | 1220 | 1250 | 1500 | |||||

| Length(mm) | 2440 | Or according to customer's request | ||||||

| Panel thickness(mm) | 2 | 3 | 4 | 5 | 6 | |||

| Aluminum thickness(mm) | 0.10 | 0.12 | 0.15 | 0.18 | 0.21 | 0.3 | 0.4 | 0.5 |

| Coating | PVDF | PE | Brush | Mirror | Glossy | Wood and stone texture | ||

4.FAQ

What is the main use for aluminium composite panel?

1) Gas piping, cables, building materials, etc (this product fills a gap

in the domestic construction materials field, with performance

indexes superior to panels manufactured overseas)

2) Curtain wall decoration for buildings where security is important,

such as airports, hospitals and research centers

3) Curtain wallboards for outside walls of normal buildings

5.

- Q:Now young people who like wood color ah, but the Chinese ah, understand the wood are very old-fashioned, including the designer in the class. The The wood is divided into two one is solid wood, one is garbage wood are labeled as small sand, together with the pressure may be different. The The Speaking of low on these two types of solid wood board is equal to two pressure into the plate on the market,

- First scraping putty, dry with sand can be polished after painting.

- Q:PCB plate manufacturers are famous what

- Sunrise, Matsushita, Arlon, Nelco, Rogers, Tanconic, polyflon, etc.

- Q:Is the cement pressure plate and the cement fiber board a plate? Is there a difference?

- Cement fiberboard and cement pressure plate is a product of two names, in fact no difference. The cementitious materials are cement, and the reinforcing materials are fibers (asbestos fibers and / or cellulose fibers). The name of the fiberboard emphasizes the reinforcement of the material 'fiber'; 'pressure plate' name emphasizes the production process, the use of presses on the board green pressure, squeeze out the water and compaction, improve the board's density and strength. 'Cement fiberboard' is a more traditional name, but in recent years is also known as 'cement pressure plate'. Advantages and Disadvantages of Cement Fiberboard Advantages: cement fiber pressure plate as a new environmentally friendly building materials, in addition to the function of the traditional gypsum board, but also has excellent fire performance and moisture resistance, the advantages of long life, a large number of industrial and commercial applications in the ceiling ceiling and partition, home decoration , Furniture liner, billboard liner, ship compartment board, warehouse floor, network floor and tunnel and other indoor works of the wall. Calcium silicate board processed into the ceiling, with resistance to subsidence, moisture, no dust, non-flammable and other characteristics, an effective solution to mineral wool board gypsum board easy subsidence, short life defects. Calcium silicate board, fiber cement pressure plate is the ideal decoration of the permanent building plate. Walls, ceiling also applies to the wall, the activities of the floor, table, billboards, goods cabinets, kitchen latrines, goods cabinets, fire Pipe, furniture liner, fire door lining. Disadvantages: easy to cause crevice cracking, and deal with the gap is too much trouble. (Thermal expansion and contraction is relatively strong in the reason)

- Q:Q235 material, 2.5mm thickness of the plate, flanging R corner of the smallest can not be less than how much? Is a material thickness? This problem is applied to similar flanging situation? Do sheet metal peers please help

- These are low carbon steel, brass, the bending factor, carbon steel bending coefficient than these data larger; are: 1.2,1.8,3.0.

- Q:Guodong E1 grade 180 plate how to identify

- Guodong is actually only a very popular in the southwest region of the logo, only a logo only, no one can identify whether it is authentic, do not mind too. Any special emphasis on your own use of the country ah LSH Ye like the plate, you should be careful. Our industry, as long as it is out from the manufacturers, are clear Guodong is not any security LOGO (and can not be tested to prove that Guodong produced), and the Guodong like the plate manufacturers are not directly The use of furniture, must be treated through the finishes will enter the furniture factory, and this finishes the process, the importance of the original sheet than ever. Or the words: the economic market, is always a penny of goods (aside from those who do not speak integrity of the business, because their behavior can not be used to measure the normal business theory) Guodong is actually only a very popular in the southwest region of the logo, only a logo only, no one can identify whether it is authentic, do not mind too. Any special emphasis on your own use of the country ah LSH Ye like the plate, you should be careful. Our industry, as long as it is out from the manufacturers, are clear Guodong is not any security LOGO (and can not be tested to prove that Guodong produced), and the Guodong like the plate manufacturers are not directly The use of furniture, must be treated through the finishes will enter the furniture factory, and this finishes the process, the importance of the original sheet than ever. Or the words: the economic market, is always a penny of goods (aside from those who do not speak integrity of the business, because their behavior can not be used to measure the normal business theory)

- Q:Do the closet with osb board with high density MDF which is better?

- Osb board is better. OSB (Oriented Strandboard) board, also known as oriented particleboard, the domestic also called the European pine board. It is a synthetic wood "OSB" source --- "Ou Song board" is the name of the directional structure of particleboard (OrientedStrandBoard, 0SB), is a from Europe, seventies and eighties in the international community to develop a new type of rapid development. "Ou Song board" (also known as "love grid") in the application of the furniture has been an unprecedented development, many large furniture companies are beginning to use "OSB" production of furniture, the reason why consumers like the lack of formaldehyde Release, and durable, and made of medium density fiberboard furniture, light weight, better flatness. High density MDF (HDF) is a kind of sheet made of wood fiber or other plant fiber as raw material, urea urea resin, or other synthetic resin under the conditions of heating and pressing. Smooth, in the ambient temperature and humidity changes, the size of good stability, easy to surface decoration treatment. The internal structure of fine, in particular, has a dense edge, can be processed into a variety of special-shaped edge, and do not have to cover the edge of the direct coating, you can achieve better shape effect. Uniform structure, inside and outside the same, so you can carry out the surface of the carved processing and processing into a variety of sections of the decorative lines, suitable for the replacement of natural wood for structural materials.

- Q:What is the difference between the addition of the plate and the Eo grade plate?

- 100% of the addition of non-formaldehyde-free plate and E0-type plate is different from the use of glue is not the same, E0-class plate is urea-formaldehyde resin, 100 wins and no use of non-formaldehyde plate is the use of formaldehyde-free US fourth generation MDI glue.

- Q:What kind of timber is the high grade guitar?

- General top or advanced guitar wood selection surface is not particularly large, generally fixed in several kinds of wood, the production of guitar is very much but in the high-grade guitar selection, the available is not particularly much (in addition to some special Creative thinking of the producer's whim). Here I give you a closer look: panel: Spruce spruce sound grain good, penetrating, cool and bright. It is the first choice for most guitar panels, which is made of German-made (Sicilia spruce) and Canadian (Inman Spruce), with high density, woody charm, hard and easy to process. The Representative Brand: H.Romannillos, Hauser, Martin, Taylor, Gibson. Cedar cedar sound deep atmosphere, strong sense of sticky, soft and warm. It is good for American-made (western pine) and Canada (Ingersel Cedar), high density, fine grain and delicate, easy to process, and now many guitar makers prefer wood (easy to process). ...). On behalf of the brand: Greg.Smallman, Kenny.Hill, Takamine, King of Recording.

- Q:What is the difference between acrylic and resin plates?

- Acrylic from English, the chemical name is abbreviated as: PMMA; PMMA, also known as polymethyl methacrylate, is made from acrylic monomer (pellet or liquid) MMA polymerization. Because the transparency is very high, can be as high as 93%, so it is also known as: plexiglass. Acrylic is not plastic, because the plastic is PVC collectively, from the use of acrylic terms: can be divided into: advertising materials, decorative materials, crafts materials. Resin board, also known as eco-resin plate (Ai Hao), chemical name: PETG PETG is a non-crystalline copolyester, PETG commonly used comonomer is 1,4-cyclohexanedimethanol (CHDM), all known as polyethylene terephthalate-1,4-cyclohexane Dimethanol ester. It is the product of polycondensation of terephthalic acid (TPA), ethylene glycol (EG) and 1,4-cyclohexanedimethanol (CHDM) by transesterification. Compared with PET, -cyclohexanedimethanol comonomer, with the PCT more than ethylene glycol comonomer, therefore, PETG performance and PET, PCT is very different. PETG sheet has outstanding toughness and high impact strength, the impact strength is modified polyacrylate 3 to 10 times, and has a wide processing range, high mechanical strength and excellent flexibility, compared to PVC transparency High, glossy, easy to print and have an environmental advantage.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

ALUMINUM PE COMPOSITE PANEL ORIGINAL CORLOR

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 6000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords